Encyclopedia of what a power plant is and who. Power plant: definition and types. Depending on the degree of application

Power plants are enterprises that generate electricity. Power plants are divided into thermal, hydraulic and nuclear. Thanks to mechanization and automation, the operation of power plants is controlled centrally. The work of personnel is characterized by great responsibility and tension.

The most favorable working conditions are at hydroelectric power plants. At nuclear power plants, radioactive radiation, aerosols and gases pose health hazards.

The main producers of electricity are powerful block-type thermal power plants using coal, shale, peat, fuel oil, and natural gas as fuel. Harmful factors are high temperatures (see), noise (see) and vibration (see). In summer, the temperature in the boiler-turbine shop reaches 30-35°, on the boiler platforms, at the deaerators and in the crane cabins - 35-50°. In winter, the microclimate is characterized by sudden temperature changes and drafts. The microclimate can be improved by careful thermal insulation of equipment and proper ventilation. It is necessary to install air conditioners in control panels and crane operator cabins. When unloading and transporting fuel, in the boiler shop and ash department, the concentrations of fuel and ash dust reach 20-100 mg/m3; when repairing and cleaning boilers - 100-500 mg/m3. Fuel oil ash can cause poisoning due to the vanadium it contains and skin diseases caused by impurities of nickel, vanadium, etc.

Reducing dust levels is facilitated by: sealing fuel supply paths, introducing dust-free methods for cleaning boilers and wet cleaning of premises. In areas with intense dust generation it is necessary to use (see). Sources of noise and vibration are turbogenerators, gas and steam pipelines, pumps, mills, etc. The total noise levels at turbines are 94-110 dB, at mills - 109-120 dB, in the boiler shop - 80-95 dB, in control panels - 70-90 dB. The noises are high frequency. General vibration parameters slightly exceed permissible levels. Reducing noise and vibration can be achieved by thoroughly sound and vibration insulation of machines. In some areas it is advisable to use antiphons (see).

Power plants are enterprises (thermal, hydraulic and nuclear) that generate electricity. The basis of the energy sector is made up of powerful block-type thermal power plants, which, in addition to electrical energy, can produce thermal energy for industrial and domestic needs in the form of steam and hot water (cogeneration). The operation of the power plant is controlled from the main switchboard, individual blocks and units from group and local switchboards. The work of driver-operators is characterized by great responsibility and tension, especially during the start-up period and in an emergency. For the rational organization of their work, control electronic computers are currently used.

The most favorable working conditions are at hydroelectric power plants (HPPs) and nuclear power plants (NPPs).

The main workshops of a thermal power plant are the boiler and turbine shops. The fuel used is coal, oil shale, peat, fuel oil and natural gas. Harmful factors are high temperatures, intense noise (see), dust (see) and toxic gases. In summer, the temperature reaches 30-35°, at the sites of water inspections, deaerators and in crane cabins - 35-50°. In winter, the microclimate is characterized by sudden temperature changes and drafts. Favorable meteorological conditions are achieved by improving the thermal insulation of equipment and proper operation of aeration systems. It is advisable to install air conditioners in the rooms of group control panels and crane operator cabins.

The highest concentrations of dust (10-50 mg/m3) are observed during unloading, crushing, transportation of fuel and in the ash room. When repairing and cleaning boilers, the dust concentration reaches 100-500 mg/m3. Aerosols of polysulfur fuel oil ash contain from 5 to 27% vanadium and up to 8-10% nickel, aerosols of coal ash contain up to 24% free silicon dioxide, and shale ash contain up to 10-20% free lime. Reducing dust levels can be achieved by installing local suction, introducing dust-free methods for cleaning boilers and wet cleaning of premises. Repair workers must use respirators (see) and special clothing.

The concentration of carbon monoxide, hydrocarbons, sulfur dioxide and sulfuric anhydrides, as a rule, does not exceed permissible values. Sources of noise are turbogenerators, steam pipelines, ejectors, pumps, mills. General noise levels for turbines range from 94 to 110 dB, for ball mills - from 109 to 120 dB, in a boiler shop - from 80 to 95 dB, in group switchboard rooms - from 70 to 90 dB. Noises are characterized by the entire frequency range, including ultrasonic. To reduce noise, it is necessary to carefully soundproof steam and gas pipelines and promptly eliminate additional noise. Antiphons should be used in certain areas.

Just a hundred years ago, an ordinary person could not even imagine how many different devices would surround him. And all current electronics, household appliances and industrial equipment use electricity in their work - from a banal lighting lamp to multifunctional processing centers in large industries.

Providing electricity is one of the most important tasks for a home, office or industry. It is quite clear that specialized equipment is used for this, meeting the needs in each specific case - power plants of various purposes and capacities.

Power plant - what is it?

According to the definition accepted in the technical literature, power plant is a complex of equipment, installations, and control equipment that ensures the production of electrical energy. In addition, power plants are all buildings and structures involved in the process of generating electricity, which belong to one enterprise and are located in a certain territory.

Almost all power plants use in their work the energy of rotation of the shaft of the main element - the generator, which actually generates electricity. The main differences between all types of such generating equipment are in size, form factor, and type of energy source, which actually rotates the shaft.

In addition to the generator itself, which is the main part of all power plants, regardless of their size, the complete set also includes other elements: power lines and connecting power lines, boilers and tanks, turbines and transformers, switches and automation equipment. All these parts, combined into a single system, form power plants of the required power and purpose.

A little history and statistics

The beginning of the development of power plants can be called the opening of the first of them. A historical event took place in September 1882 in New York, where Thomas Edison's company opened the first thermal station that powered an entire area of the city. Also in 1882, the first hydroelectric power station appeared, providing electricity to two paper mills and the private house of the owner of the company that implemented this project.

For Russia, the era of electrification began in 1886 - it was in this year that a thermal power plant was successfully launched, which guaranteed illumination, first only of the Winter Palace, and then of all the utility rooms and Palace Square. The station operated on hard coal and successfully demonstrated the possibility of providing a large number of consumers with inexpensive and high-quality energy. This year should be considered the beginning of the successful, albeit rather slow, electrification of the country. With the advent of Soviet power, the pace of creating a single powerful energy system increased significantly - just remember the famous Goelro plan, which successfully provided even remote settlements of the Soviet Union with “Ilyich light bulbs”.

The development of technology has not ignored the energy sector. In addition, humanity has long been concerned about the gradual depletion of natural resources, which also led to a change in energy sources and the usual coal, gas, and oil are gradually being replaced by renewable resources - wind, solar, tidal energy, and nuclear energy. Naturally, new types of energy require new technological solutions that ensure not only proper use, but also complete safety of any power plant.

Taking into account the specifics of their own natural resources, traditional energy in different countries and continents has received different main directions of development: thermal, nuclear, and hydropower currently generate the overwhelming majority of all electricity in the world. More than 90% of all power plants in the world operate using liquid, solid and gaseous fuels - oil products, coal, gas. Their use predominates in the energy systems of not only our country, but also other countries - China, Mexico, Australia.

Hydroelectric power plants make it possible to successfully use a directed and concentrated water jet as a propulsion device for turbines, with only minimal impact on the environment. In Brazil and Norway, almost all of the electricity produced is generated by hydroelectric power plants, which is facilitated by the availability of large amounts of water resources.

A striking example of countries where nuclear energy predominates are France and Japan. Without their own reserves of coal or gas, these countries, with the discovery of the possibility of using a controlled nuclear reaction, almost completely switched to electricity generated by nuclear plants.

Home power plant is not a dream

A natural direction in the energy sector is the development of compact energy sources. Even a small diesel power plant is an opportunity to provide an office building, a work village or several houses with an uninterrupted supply of electricity. Often, such options are the only possible way to enable remote fields to operate, especially in permafrost or polar station conditions. Conventional power sources for power plant generators in places where it is impossible to install conventional power lines are gradually being replaced by alternative options - wind generators, solar panels, power plants powered by tidal or surf energy.

Due to their compactness, alternative methods of generating electricity are gaining great popularity among individuals. One relatively small wind turbine can easily provide electricity for a private household, and if you approach the process comprehensively, adding a solar station and batteries to the system, you can get an excellent autonomous home. Among other things, non-standard options for generating electricity can significantly reduce its cost, which in modern conditions is an important factor. It is alternative methods of energy supply that allow us to safely say that in the near future it will be the case that a compact home power plant is not a luxury, but a completely affordable and safe source of electricity for every family.

Power plants are used to supply electricity to stationary and mobile objects. They are a set of installations, apparatus and equipment that are used to produce electricity, together with the buildings and structures necessary for this, located in a certain area. Modern power plants can start up in a short time and are protected from precipitation and mechanical impact. The largest projected is the Evenki hydroelectric power station.

Why are power plants needed?

The power plant can easily be called one of the most important structures necessary to ensure the livelihoods of the population. Without electricity today, not a single settlement or enterprise can exist. Modern power plants are built far from densely populated areas, consist of a complex of buildings and installations, and are divided into various types and types, united by a common principle. It lies in the fact that they all operate from a system of generators that produce energy through shaft rotation.

Types of power plants

According to the method of generating energy, power plants are divided into:

- atomic. Energy is produced by nuclear reactors and a number of specialized installations and systems;

- thermal. The main one is external fuel, which, when burned, creates energy to turn the generator shaft;

- hydroelectric power stations. The main “force” is the natural energy of the rivers on which dams are installed;

- wind power plants. Depends on air masses;

- geothermal. They are powered by underwater thermal sources;

- sunny. Absorb and convert solar energy.

According to their purpose, power plants are divided into the following types:

- power. Necessary for power supply to large consumers, such as cities and factories;

- chargers. They are used to charge various accumulators and batteries, equipped with chargers, and the power plant must also include a DC electric drive;

- lighting Equipped with a complete set of spotlights and lamps, designed for illuminating business facilities and construction sites;

- special. Used for welding and other types of work.

Power plants are also divided into:

- into variable and constant (according to the type of current);

- for diesel and gasoline (by engine type);

- for high-, medium- and low-power (in terms of power);

- for low and high voltage (voltage).

Electrical energy, which began to be actively used, by historical standards, not so long ago, has significantly changed the life of all mankind. Currently, different types of power plants produce huge amounts of energy. Of course, for a more accurate representation, specific numerical values could be found. But for qualitative analysis this is not so important. It is important to note the fact that electrical energy is used in all spheres of human life and activity. It is even difficult for a modern person to imagine how it was possible to do without electricity just a hundred years ago.

The high demand also requires corresponding generating capacities. To generate electricity, as people sometimes put it in everyday life, thermal, hydraulic, nuclear and other types of power plants are used. As is not difficult to notice, the specific type of generation is determined by the type of energy that is required to generate electric current. At hydroelectric power plants, the energy of water flowing from a height is converted into electric current. In the same way, gas-fired power plants convert the thermal energy of burning gas into electricity.

Everyone knows that the law of conservation of energy operates in nature. All of the above inherently transform one type of energy into another. A chain reaction occurs in the decomposition of certain elements with the release of heat. This heat is converted into electricity through certain mechanisms. Thermal power plants operate on exactly the same principle. Only in this case, the source of heat is organic fuel - coal, fuel oil, gas, peat and other substances. The practice of recent decades has shown that this method of generating electricity is very expensive and causes significant damage to the environment.

The problem is that the planet's supplies are limited. They should be used sparingly. The progressive minds of mankind have long understood this and are actively searching for a way out of this situation. One of the possible exit options is considered to be alternative power plants that operate on different principles. In particular, sunlight and wind are used to generate energy. The sun will always shine and the wind will never get tired of blowing. As experts say, these are inexhaustible or need to be used rationally.

More recently, the list of types of power plants was short. There are only three positions - thermal, hydraulic and atomic. Currently, several well-known companies in the world are conducting serious research and development in the field of solar energy. As a result of their activities, converters of sunlight into electricity appeared on the market. It should be noted that their efficiency still leaves much to be desired, but this problem will be solved sooner or later. The situation is exactly the same with the utilization of wind energy. are becoming more widespread.

3.4. EARLY POWER PLANTS

Power plants, which are understood as factories for the production of electrical energy to be distributed among various producers, did not appear immediately. In the 70s and early 80s of the XIX century. the place of electricity production was not separated from the place of consumption.

Electric stations that provided electricity to a limited number of consumers were called block stations (not to be confused with the modern concept of block stations, by which some authors understand factory-based thermal power plants). Such stations were sometimes called “brownie” stations.

The development of the first power plants involved overcoming difficulties not only of a scientific and technical nature. Thus, city authorities prohibited the construction of overhead lines, not wanting to spoil the appearance of the city. Competing gas companies did their best to emphasize the real and imaginary shortcomings of the new type of lighting.

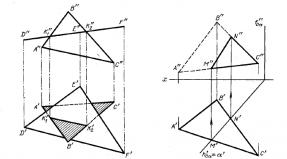

At block stations, mainly piston steam engines and, in some cases, internal combustion engines (which were a novelty at that time) were used as prime movers; locomotives were widely used. A belt drive was made from the prime mover to the electric generator. Typically, one steam engine drove one to three generators; Therefore, several steam engines or locomobiles were installed at large block stations. To adjust the belt tension, electric generators were mounted on skids. In Fig. Figure 3.7 shows a view of a power plant for lighting one house.

For the first time, block stations were built in Paris to illuminate the street of the Opera. In Russia, the first installation of this kind was the lighting station for the Liteiny Bridge in St. Petersburg, created in 1879 with the participation of P.N. Yablochkova.

Rice. 3.7. Block station - a power station with two generators (bottom right) and a locomobile (left) for lighting one house

However, the idea of centralized electricity production was so economically justified and so consistent with the trend of concentration of industrial production that the first central power plants arose already in the mid-80s of the 19th century. and quickly replaced the block stations. Due to the fact that in the early 80s only light sources could become mass consumers of electricity, the first central power plants were designed, as a rule, to power the lighting load and generate direct current.

In 1881, several enterprising American financiers, impressed by the success that accompanied the demonstration of incandescent lamps, entered into an agreement with T.A. Edison and began construction of the world's first central power station (on Pearl Street in New York). In September 1882, this power plant was put into operation. Six T.A. generators were installed in the station's turbine room. Edison, the power of each was about 90 kW, and the total power of the power plant exceeded 500 kW. The station building and its equipment were designed very expediently, so that in the future, during the construction of new power plants, many of the same principles that were proposed by T.A. were developed. Edison. Thus, the station generators were artificially cooled and connected directly to the engine. The voltage was adjusted automatically. The station provided mechanical fuel supply to the boiler room and automatic removal of ash and slag. Equipment was protected from short circuit currents by fuses, and the main lines were cable. The station supplied electricity to a vast area of 2.5 km at that time.

Soon several more stations were built in New York. In 1887, 57 central power plants of the T.A. system were already operating. Edison.

The initial voltage of the first power plants, from which others were subsequently produced, forming the well-known voltage scale, developed historically. The fact is that during the period of exceptional distribution of arc electric lighting, it was empirically established that the most suitable voltage for arc burning is 45 V. To reduce short circuit currents that arose at the moment of ignition of the lamps (when the coals came into contact), and for more stable combustion arcs were connected in series with the arc lamp with a ballast resistor.

It has also been empirically found that the resistance of the ballast resistor should be such that the voltage drop across it during normal operation is approximately 20 V. Thus, the general voltage in DC installations was initially 65 V, and this voltage was used for a long time. However, two other lamps were often included in one circuit, the operation of which required 2x45 = 90 V, and if we add another 20 V to this voltage due to the resistance of the ballast resistor, we get a voltage of 110 V. This voltage was almost universally accepted as the standard .

Already when designing the first central power plants, difficulties were encountered that were not sufficiently overcome during the entire period of the dominance of direct current technology. The radius of power supply is determined by the permissible voltage losses in the electrical network, which for a given network are smaller, the higher the voltage. It was this circumstance that forced the construction of power plants in the central areas of the city, which significantly complicated not only the provision of water and fuel, but also increased the cost of land for the construction of power plants, since land in the city center was extremely expensive. This, in part, explains the unusual appearance of New York power plants, where equipment was located on many floors. The situation was further complicated by the fact that the first power plants had to install a large number of boilers, the steam production of which did not meet the new requirements imposed by the electric power industry.

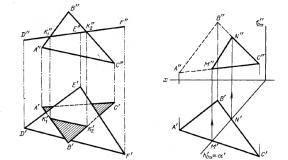

Our contemporary would be no less surprised to see the first St. Petersburg power plants that served the Nevsky Prospekt area. In the early 80s of the XIX century. they were placed on barges secured at berths on the Moika and Fontanka rivers (Fig. 3.8). The builders proceeded from considerations of cheap water supply; in addition, with this decision there was no need to buy land plots close to the consumer.

In 1886, the joint-stock “Electric Lighting Society of 1886” was established in St. Petersburg (abbreviated as “Society of 1886”), which acquired power plants on the Moika and Fontanka rivers and built two more: near the Kazan Cathedral and on Engineering Square. The power of each of these power plants barely exceeded 200 kW.

Rice. 3.8. Power plant on the river Fontanka in St. Petersburg

In Moscow, the first central power station (Georgievskaya) was built in 1886, also in the city center, on the corner of Bolshaya Dmitrovka and Georgievsky Lane. Its energy was used to illuminate the surrounding area. The power of the power plant was 400 kW.

The limited ability to expand the radius of power supply has meant that meeting the demand for electricity has become increasingly difficult over time. Thus, in St. Petersburg and Moscow, by the mid-90s, the possibilities of connecting a new load to existing power plants had been exhausted and the question arose about changing network diagrams or even changing the type of current.

The growing demand for electricity effectively stimulated an increase in the productivity and efficiency of the thermal part of power plants. First of all, we should note the decisive turn from piston steam engines to steam turbines. The first turbine at Russian power plants was installed in 1891 in St. Petersburg (station on the Fontanka River). A year before, a turbine test was carried out at a station located on the river. Moika. The most significant drawback of direct current power supply has already been noted above - the area of the region is too small, which can be served by a central power station. The load distance did not exceed several hundred meters. Power plants sought to expand the circle of consumers of their product - electricity. This explains the persistent search for ways to increase the area of power supply, subject to the preservation of already built DC stations. Several ideas have been proposed to increase the radius of energy distribution.

The first idea, which did not gain noticeable popularity, concerned lowering the voltage of electric lamps connected at the end of the line. However, calculations showed that with a network length of more than 1.5 km, it was more economically profitable to build a new power plant.

Another solution, which could in many cases satisfy the need, was to change the network design: moving from two-wire networks to multi-wire networks, i.e. actually increases the voltage

A three-wire power distribution system was proposed in 1882 by J. Hopkinson and independently by T. Edison. With this system, the generators at the power plant were connected in series and a neutral, or compensation wire, ran from a common point. At the same time, ordinary lamps were retained. They were switched on, as a rule, between the working and neutral wires, and the motors could be switched on at a higher voltage (220 V) to maintain load symmetry.

The practical results of the introduction of a three-wire system were, firstly, an increase in the radius of power supply to approximately 1200 m, and secondly, a relative saving of copper (under all other identical conditions, copper consumption with a three-wire system was almost half as much as with a two-wire system).

To regulate the voltage in the branches of a three-wire network, various devices were used: regulating additional generators, voltage dividers, in particular the voltage dividers of Mikhail Osipovich Dolivo-Dobrovolsky, which have become widespread, and rechargeable batteries. The three-wire system was widely used both in Russia and abroad. It survived until the 20s of the 20th century, and in some cases it was used later.

The maximum version of multi-wire systems was a five-wire DC network, in which four series-connected generators were used and the voltage was quadrupled. The radius of power supply increased to only 1500 m. However, this system was not widely used.

The third way to increase the radius of power supply involved the construction of battery substations. Batteries were a mandatory addition to every power plant at that time. They covered peak loads. Charging during the day and late at night, they served as a reserve.

Networks with battery substations have become somewhat widespread. In Moscow, for example, in 1892, a battery substation was built in the Upper Trading Rows (now GUM), located at a distance of 1385 m from the Georgievskaya central station. At this substation, batteries were installed that powered about 2,000 incandescent lamps.

In the last two decades of the 19th century. Many DC power plants were built and for a long time they contributed a significant share of total electricity generation. The power of such power plants rarely exceeded 500 kW; units usually had a power of up to 100 kW.

All possibilities for increasing the radius of power supply with direct current were quickly exhausted, especially in large cities.

In the 80s of the XIX century. AC power plants are beginning to be built, the benefits of which for increasing the radius of power supply were undeniable. Apart from the alternating current block stations built in England in 1882–1883, then, apparently, the first permanently operating alternating current power station can be considered the Growner Gallery power station (London). At this station, put into operation in 1884, two alternating current generators by W. Siemens were installed, which, through series-connected transformers by J.D. Golyar and L. Gibbs worked on the lighting of the gallery. The disadvantages of series connection of transformers and, in particular, the difficulties of maintaining a constant current were identified quite quickly, and in 1886 this station was reconstructed according to the design of S.Ts. Ferranti. Generators by W. Siemens were replaced by machines designed by S.Ts. Ferranti with a power of 1000 kW each with a terminal voltage of 2.5 kV. Transformers manufactured according to the design of S.Ts. Ferranti were connected in parallel to the circuit and served to reduce voltage in the immediate vicinity of consumers.

In 1889–1890 S.Ts. Ferranti returned to the problem of electricity supply in London with the goal of providing electricity to the City of London area. Due to the high cost of land in the city center, it was decided to build a power station in one of the outskirts of London, in Deptford, located 12 km from the City. Obviously, at such a great distance from the place of electricity consumption, the power plant had to generate alternating current. During the construction of this installation, powerful high-voltage generators (10 kV) with a power of 1000 hp were used at that time. The total capacity of Deptford Power Station was approximately 3000 kW. At four city substations, fed by four main cable lines, the voltage was dropped to 2400 V, and then at consumers (in homes) - to 100 V.

An example of a large hydroelectric power station that fed a lighting load in a single-phase circuit is the station built in 1889 at a waterfall near Portland (USA). At this station, hydraulic motors drove eight single-phase generators with a total power of 720 kW. In addition, 11 generators were installed at the power plant, designed specifically to power arc lamps (100 lamps per generator). The energy from this station was transmitted over a distance of 14 miles to Portland.

A characteristic feature of the first alternating current power plants is the isolated operation of individual machines. Synchronization of generators had not yet been carried out, and a separate circuit went from each machine to consumers. It is easy to understand how uneconomical electrical networks turned out to be under such conditions, the construction of which required enormous amounts of copper and insulators.

In Russia, the largest alternating current stations were built in the late 80s and early 90s of the 19th century. The first central power plant was built by the Hungarian company Ganz and Co.? in Odessa in 1887. The main consumer of energy was the single-phase electric lighting system of the new theater. This power plant was a progressive structure for its time. It had four water-tube boilers with a total capacity of 5 tons of steam per hour, as well as two synchronous generators with a total power of 160 kW at a terminal voltage of 2 kV and a frequency of 50 Hz. From the distribution board the energy was fed into a 2.5 km line leading to the theater's transformer substation, where the voltage was reduced to 65 V (which incandescent lamps were designed for). The equipment of the power plant was so advanced for its time that, despite the fact that imported English coal served as fuel, the cost of electricity was lower than at later St. Petersburg and Moscow power plants. Fuel consumption was 3.4 kg/(kWh) [at St. Petersburg power plants 3.9–5.4 kg/(kWh)].

In the same year, operation of a direct current power station began in Tsarskoye Selo (now the city of Pushkin). The length of the overhead network in Tsarskoe Selo already in 1887 was about 64 km, while two years later the total cable network of the “Society of 1886” in Moscow and St. Petersburg was only 115 km. In 1890, the Tsarskoye Selo power station and network were reconstructed and transferred to a single-phase alternating current system with a voltage of 2 kV. According to contemporaries, Tsarskoe Selo was the first city in Europe that was illuminated exclusively by electricity.

The largest power plant in Russia for supplying a single-phase alternating current system was the station on Vasilievsky Island in St. Petersburg, built in 1894 by engineer N.V. Smirnov. Its power was 800 kW and exceeded the power of any direct current station that existed at that time. Four vertical steam engines with a power of 250 hp were used as prime movers. each. The use of an alternating voltage of 2000 V made it possible to simplify and reduce the cost of the electrical network and increase the radius of power supply (more than 2 km with a loss of up to 3% of voltage in the main wires instead of 17–20% in DC networks). Thus, the experience of operating central stations and single-phase networks has shown the advantages of alternating current, but at the same time, as already noted, it has revealed the limitations of its use. The single-phase system slowed down the development of the electric drive and complicated it. For example, when connecting a power load to the Deptford station network, it was necessary to additionally place an accelerating AC commutator motor on the shaft of each synchronous single-phase motor. It is easy to understand that such a complication of the electric drive made the possibility of its widespread use very doubtful.