Insulation of the basement of an old brick house. Insulation of the foundation base from the outside: technologies and materials used, stages of work. Various finishing options available

The basement is the upper part of the foundation located above the ground, which serves as a support for the ceiling of the first floor and the outer walls of the house. In fact, it can be considered the most vulnerable part of the house, since, in addition to the load from the walls, the base is also exposed to a large amount of moisture. But at the same time it protects against cold air and moisture entering the house.

External and internal thermal insulation

It has been practically proven that competently executed insulation of a foundation with a plinth provides more than 25% savings on heating.

First of all, it should be noted that high-quality waterproofing with insulation is a complex measure, which includes not only thermal insulation of the basement walls with the foundation, but also insulation of the blind area running along the entire perimeter of the building. Otherwise, there is most likely no need to talk about any high effectiveness of these measures.

The soil, if all the insulation work is done correctly, does not freeze at all near the foundation walls.

Why do you need basement insulation?

Since the base is part of the foundation, this structural element also needs to be insulated for several reasons, and, first of all, this is necessary to increase its strength, and therefore durability. Naturally, the operational resources of the entire building will depend on these factors.

Since the base is part of the foundation, this structural element also needs to be insulated for several reasons, and, first of all, this is necessary to increase its strength, and therefore durability. Naturally, the operational resources of the entire building will depend on these factors.

If massive monolithic foundation made of reinforced concrete or prefabricated foundation blocks is not covered with thermal insulation on the outside, then in winter frosts it will turn into a powerful cold accumulator. This cold will be transferred to other building structures adjacent to the foundation or plinth, which will ultimately lead to unnecessary heat loss and additional heating costs.

Theoretically, it is possible to insulate the base not only from the outside, but also from the inside, only in this case the effectiveness of preserving the foundation and the walls of the base will be completely different.

Thermal insulation of the room

When installing internal insulation, it is possible to achieve high insulation from the penetration of cold into the premises of the building, but at the same time the walls will freeze, and condensation will accumulate between them and the internal insulation, which will gradually destroy the walls of the basement. As a result, microcracks will begin to appear, into which moisture will penetrate and accumulate. In cold weather, it will freeze and expand the cracks, which will ultimately cause the walls to crumble and reduce their strength.

When installing internal insulation, it is possible to achieve high insulation from the penetration of cold into the premises of the building, but at the same time the walls will freeze, and condensation will accumulate between them and the internal insulation, which will gradually destroy the walls of the basement. As a result, microcracks will begin to appear, into which moisture will penetrate and accumulate. In cold weather, it will freeze and expand the cracks, which will ultimately cause the walls to crumble and reduce their strength.

Therefore, internal insulation is sometimes compared to a mine, which has a delayed action. This method only contributes to through freezing of the walls, accumulation of moisture and their slow destruction.

The most reasonable solution would be to block the passage of cold from the outside of the foundation so that its thermal insulation layer is connected to the insulation of the base. In this case, the underground and above-ground foundation will have the same temperature conditions, due to which various internal stresses will not arise in it due to temperature differences.

External work during foundation construction

Thanks to the external location of thermal insulation Condensation does not form in the wall itself, since it does not freeze and is not affected by temperature changes. Thanks to this, the risks of concrete erosion that occur under the influence of humidity and temperature changes are sharply reduced.

Thanks to the external location of thermal insulation Condensation does not form in the wall itself, since it does not freeze and is not affected by temperature changes. Thanks to this, the risks of concrete erosion that occur under the influence of humidity and temperature changes are sharply reduced.

The risk of corrosion of the reinforcement cage is also greatly reduced. concrete foundation. In addition, the outer layer of thermal insulation plays the role of an additional barrier against the penetration of moisture into the base from the underground part of the foundation into its walls and protects the insulation itself from external mechanical damage.

As a result, by making external insulation of the base and foundation, you can get a warm building and extend its operational capabilities.

Insulation for the base

Before you insulate the basement of the house from the outside with your own hands, you should choose high-quality insulation for this. . Material selected for external insulation basement walls must have:

- Minimum thermal conductivity.

- Zero absorbed moisture.

- High resistance against various microorganisms.

Also, an important role when choosing insulation is played by its durability, which determines the timing of periodic repairs of the base.

Also, an important role when choosing insulation is played by its durability, which determines the timing of periodic repairs of the base.

Today, the building materials market offers only two types of insulation for basement walls that fully comply with the requirements - these are slab materials and sprayed polymer-based insulation.

Features of polystyrene (foam)

This material has been used as insulation for quite a long time. Moisture does not accumulate in it, it retains heat well, is easy to process and, due to its light weight, can be easily glued to the walls of the foundation and plinth on your own.

Polystyrene foam is produced by steaming granules consisting of isopentane and pentane. Under the influence of temperature, pentane evaporates, and the granule increases in size and takes on the shape of a ball.

The disadvantage of this material is its fragility and ability to allow moisture to pass into the top layer. And if polystyrene foam not protected by waterproofing, then the moisture that gets into it during freezing will provoke its crumbling.

Extruded polystyrene foam

This material has a dense structure with practically zero water absorption and great mechanical strength, is resistant to the effects of microorganisms, does not rot and does not deform under significant loads.

This material has a dense structure with practically zero water absorption and great mechanical strength, is resistant to the effects of microorganisms, does not rot and does not deform under significant loads.

Extruded polystyrene foam has proven itself to be excellent for external insulation of surfaces that are located in the ground and are constantly exposed to groundwater.

Since this material almost does not allow air to pass through, it is not recommended to be used for insulating wooden surfaces, but for insulating a concrete base and brick walls, this material is practically ideal option thermal insulation.

Disadvantages include high cost and the release of toxic gases during combustion or smoldering.

Features of the sprayed material

This material includes polyurethane foam, which immediately performs several functions of sound insulation, waterproofing and thermal insulation of the house. It can be used to insulate almost any part of the house, from the roof to the base of the foundation.

This material includes polyurethane foam, which immediately performs several functions of sound insulation, waterproofing and thermal insulation of the house. It can be used to insulate almost any part of the house, from the roof to the base of the foundation.

Polyurethane foam has high adhesion to almost any building materials. Its main advantage over other insulation materials lies in the fact that after spraying, one solid coating is formed, without any seams. The coating itself is strong and quite durable.

The only drawback of this insulation is the need to have special equipment for its application and certain skills to work with it.

How to properly insulate a basement

An uninsulated base without waterproofing cannot be considered a reliable and complete foundation for a residential building. To exclude any reasons for the decrease in strength foundation, you need to insulate its walls only from the outside. This will guarantee that such a residential building will not need repairs for a long time.

Even in the case when it is planned to build a basement in which internal, fairly high-quality thermal insulation will be made, this can only be considered as maintaining a certain microclimate in the basement. But the problem of freezing walls and the accumulation of destructive moisture in them will remain.

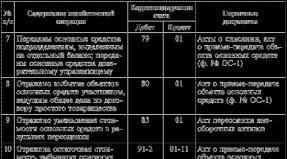

Sequence of base insulation:

Insulation of the blind area

Do not forget that the blind area also refers to the insulation of the foundation. It must be at least 200 mm wider than the overhang of the roof of the house, while its width, regardless of the building, must be at least 600 mm.

The blind area is insulated as follows:

Proper insulation from the outside will be a guarantee long-term operation Houses.

Insulating the foundation base from the outside is a labor-intensive and difficult job, but if you follow the recommendations and strictly follow the order of laying the material, you will get a result that will keep the house warm for many years. Before starting thermal insulation work, it is necessary to study the structural features of the house. A competent approach will save on heating costs and protect the foundation from deformation.

Insulation of the foundation base will avoid its destruction and deformation

Benefits of thermal insulation

Insulating the basement in a private house from the outside protects it from negative influence underground groundwater and precipitation, thereby improving the microclimate not only in residential premises, but also in the basement of the house.

Thermal insulation protects the base from freezing and mechanical damage

Thermal insulation protects the base from freezing and mechanical damage Such a structure will last much longer without overhaul. On the walls of an insulated basement no condensation forms, it saves Construction Materials from premature destruction.

Internal thermal insulation performs similar functions. As practice shows, external and internal insulation has the same result. The difference between them is only external.

For internal insulation, finishing from decorative materials is used for greater attractiveness. Whereas the inner lining is often left simply plastered.

You will see how to properly insulate a foundation with polystyrene foam yourself from this video:

Material characteristics

The foundation, along with other structures of the house, needs to be insulated. It is important to choose the right insulator, taking into account the structure of not only the base, but also the house. Materials for thermal insulation of the base:

- Expanded clay. Frost-resistant material made from baked clay. It is used as bulk insulation around the perimeter of the base. Strong, durable, has high thermal insulation properties, does not burn or rot. Environmentally friendly and inexpensive. Disadvantages of expanded clay: additional preparation is required when working, high material consumption.

- Mineral wool (stone, slag, glass wool, ceramic wool). Used to insulate the base from the inside. Doesn't burn, holds heat well, absorbs noise. Does not rot, does not deform, does not shrink. Mineral wool is resistant to chemicals, is easier to install, and has a reasonable price. Disadvantages include vapor permeability and the need to use special protective materials. Cotton wool crumbles and can cause irritation to the skin and respiratory tract when working with it.

Mineral wool is fire-resistant, does not rot, and has excellent thermal insulation properties

Mineral wool is fire-resistant, does not rot, and has excellent thermal insulation properties - Warm plaster. A viscous mixture, which may include polystyrene, vermiculite, and sawdust. Advantages of the material: allows you to create an even layer without seams, has an acceptable cost. The work can be carried out independently, in a short time. Plaster cladding has several disadvantages. The coating is heavy and creates a load on the foundation. If you apply a layer of more than 5 cm, the plaster will begin to crumble over time. Absorbs moisture, so waterproofing is required. This insulation cannot be left without finishing; it is primed and facing materials for the foundation (stone, panels) are used.

- Styrofoam. The material is cheap, durable, easy to process. Retains heat well and allows for sheathing work to be carried out in a short time. It has some disadvantages: fragile, able to absorb moisture, smells unpleasant when burning, freezes at too low a temperature, is damaged by rodents, loses its properties when exposed to ultraviolet radiation.

- Polystyrene, penoplex. Foam material. This type of insulation has many advantages. It has good thermal insulation qualities, is not afraid of temperature changes, and almost does not absorb moisture. The material is dense, durable, and can withstand mechanical loads. With proper installation, the service life is more than 25 years. Inexpensive and lightweight penoplex is easy to transport and install (it is easy to cut into pieces of the desired size). The material has significant drawbacks. It is vapor permeable, so additional protection is required. Fire hazardous; when ignited, it emits a pungent odor.

Penoplex - heat-resistant and moisture-resistant, but vapor-permeable material

Penoplex - heat-resistant and moisture-resistant, but vapor-permeable material - Foamed polyurethane (polyurethane foam). Lightweight, durable, resistant to temperature changes, exposure to oils, solvents and acids, does not mold. The service life of polyurethane is more than 40 years. It is easy to install and does not require careful surface preparation. Disadvantages of polyurethane foam: flammable, melts, produces unpleasant smoke.

- Thermal panels. Multilayer material with insulation inside, usually in the form of slabs. Consists of polyurethane foam with a special protective coating. On the outside, the decorative layer can imitate any facing material. When installing, you need to coat the material well with adhesive and additionally secure it with dowels. If the foundation is uneven, you need to make a sheathing. Thermal panels are an expensive facing material.

- Surface preparation. A trench at least 1 m wide is dug along the perimeter of the foundation. The base of the house is cleaned of dirt and flaking concrete. The part that was underground is treated especially carefully. First you need to walk over the surface with a wire brush, and then rinse with water from a spray bottle. After this, allow the foundation to dry completely for several days.

- Arrangement of drainage. If they pass close to the house groundwater, it is often flooded, so it is necessary to equip drainage. The bottom of the dug trench is covered with sand, then a layer of geotextile is laid out, and then a layer of gravel. The last stage of drainage is the installation of a perforated pipe, its end is brought to the collector. Next, the pipe must be wrapped in geotextile and covered with a mixture of sand and gravel.

- Priming the base. It is important to check for potholes and cracks in the walls. To seal irregularities, a latex-based composition is used. The primer will fill all the depressions present on the surface, and will also better connect the sheathing layer to the foundation.

- Basement waterproofing. It must be carried out so that moisture does not get on the concrete. It is convenient to use polyurea for the waterproofing layer; it is easy to apply and can last more than 30 years. After applying a liquid layer of this insulation, a thin but durable film is formed on the surface. You can also use liquid rubber for waterproofing. Its service life is shorter, but it costs much less. The product is sold ready for use; it must be applied to the surface of the base with a spatula.

- Insulation fasteners. The insulator sheets begin to be installed from the corner of the foundation from bottom to top. It is recommended to glue the insulation in a checkerboard pattern so that the seams do not coincide with the previous layer. The insulator coated with glue is pressed well against the base and held for several seconds. On the lower part of the foundation, which is then covered with earth, the material is not further strengthened. On the part that remains open, the insulation must be secured with dowels. Use a drill to drill holes in the insulator and concrete so that the dowels extend 4 cm into the foundation. The size of the nails can be different, it all depends on the thickness of the insulation. Upon completion of installation of the insulator, all seams are treated with bitumen putty or polyurethane foam.

It is recommended to install insulation boards in a checkerboard pattern

It is recommended to install insulation boards in a checkerboard pattern - Backfilling the trench. After all the cracks and gaps have been sealed, the trench is backfilled. It is necessary to lay out the first layer of coarse sand. A mixture of gravel and sand is poured over it.

- Plastering the surface. To protect the insulation from moisture that accumulates after rains at the base of the foundation, a fiberglass mesh is attached to the walls, which acts as reinforcement. Then the foundation is plastered.

For independent work Expanded polystyrene is most often chosen.

Installation of sheathing on the plinth

You can insulate the basement of a house from the outside with your own hands both during construction and during operation of the house. Stages of installation of thermal insulation:

Manufacturing of concrete blind area

Any foundation requires a concrete blind area. It varies from 80 cm to 2 m, it all depends on the characteristics of the soil. If the trench is filled with sand and gravel mixture, the blind area is made 1 m wide.

Concrete blind area is necessary to protect the foundation from moisture

Concrete blind area is necessary to protect the foundation from moisture First you need to do formwork, which prevents the concrete solution from spreading. The mixture of gravel and sand is leveled with a rake. Next, pegs are driven around the entire perimeter, and a frame of boards is installed in front of them.

The blind area is performed with a slope so that water does not linger at the foundation and moves away from the wall of the building. Then they begin to fill the blind area with concrete. If desired, tiles are laid on top of the concrete base. The foundation is finished with decorative stone or tiles after the plaster has dried. You can limit yourself to simple painting.

It is not difficult to insulate the basement from the outside. This work will take no more than 3-4 days, but the result will please you for many years. The house will be reliably protected from bad weather and rapid destruction.

Contents:

Before insulating the base of a house (i.e., its foundation part), you should take into account that this procedure is no less important than the thermal insulation of its walls and roof.

The fact is that in certain types of buildings, heat leaks through an unprotected base can reach 40% of the total losses, which significantly reduces the effectiveness of thermal insulation measures.

We also note that, despite the importance of insulating the basement wooden house, providing comfortable living conditions in it, this procedure can easily be done with your own hands.

Insulation of the basement of a wooden building is mandatory in the situations indicated below:

- if there is a subfloor (basement) in the house;

- if there are drafts in living rooms (despite the protection of the walls and roof);

- in case of freezing of the foundation base in severe frosts;

- with close proximity to cold groundwater;

- when condensation forms on window glass, which is sure sign high humidity in rooms.

It is known that the insulation of the base can be organized both from the inside and from the outside. At the same time, it is mistakenly believed that in any case, in order to achieve the required effect, the basement must be heated.

Insulating the basement of a house is no less important than insulating the walls and roof

However, practice has shown that with proper insulation of the basement from the outside, basement spaces do not need additional heating. This method of thermal insulation of the basement part of the building will be considered by us as the main one.

Choosing a material for insulating the base from the outside

Before insulating the basement of a house from the outside, you should familiarize yourself with the list of thermal insulation materials that are traditionally used for these purposes.

These may include classic polystyrene foam, polyurethane foam, mineral wool, as well as polystyrene foam and expanded clay.

Based on the fact that the basement of a wooden building is located in a zone of high humidity, experts recommend using materials with low level hygroscopicity.

Representatives of cellular heat insulators, such as, for example, polystyrene foam, polystyrene foam or polyurethane foam, have this property.

Most often used to insulate the basement of a house: expanded polystyrene, expanded clay and polyurethane foam

All these materials are available in the form of standard plates and are ideal for insulating the base from the outside, as they have the following remarkable properties:

- they provide a high level of thermal protection;

- are produced in the form of plate blanks, very easy to install;

- All these heat insulators are resistant to moisture (they are characterized by reduced hygroscopicity).

Note! For the purposes we have outlined (thermal protection of the base of a wooden building from the outside), expanded clay can also be used, however, due to its increased hygroscopicity, it is used only in exceptional cases.

Scope of work

A competent approach to thermal insulation of the base with your own hands involves a number of activities, including preparatory work.

The latter boil down to preparing a small trench about half a meter wide, dug along the base of the house to the depth of the foundation foundation and freeing up space for thermal insulation work.

To carry out work on insulating the base of the house, it is necessary to dig a trench 0.5 meters wide to the depth of the foundation along the base of the house

In addition, during the preparatory activities, the base is cleaned of dirt, and, if necessary, its surfaces are further leveled.

Direct insulation of the base with your own hands is organized according to the following scheme:

- first, a waterproofing coating is applied to the insulated surfaces;

- then the heat insulation plates themselves are attached on top of the waterproofing layer (using a special wood frame or without it);

- at the final stage of work, the protected basement part of the building is covered with the material you have chosen decorative material(lining or siding, for example).

Let us consider each of these operations in more detail.

Waterproofing

A waterproofing layer is necessary to protect the insulating material from moisture accumulating in the basement of the building and threatening its gradual destruction.

To waterproof the base and foundation, it is recommended to use a special coating based on bitumen mastic, applied to a well-leveled surface of the base (preferably in two layers).

To ensure waterproofing of the base, bitumen mastic is used

Important! When forming a two-layer coating, it is allowed to begin re-processing it only after the previous layer has completely dried.

Frame making

To place and fix plate-type insulation, it is most convenient to use a special frame made of wood beams, stuffed over the waterproofing and ensuring that the heat insulation plates are held within the protective coating.

On the surfaces of the base, the beams are fixed horizontally or vertically (depending on how the decorative cladding panels are intended to be fastened). The step for installing them yourself is selected in accordance with the width of the heat-insulating plates you have chosen, which are placed closely in the spaces between the bars.

Note! The cross-section of wooden lumber blanks is selected based on the thickness of the do-it-yourself thermal insulation plates.

Installation of insulation

Thermal protection of the base with foam plastic (expanded polystyrene) can be organized in two ways:

If the surface of the base is planned to be plastered upon completion of the thermal insulation work, then the polystyrene foam plates are simply glued onto it and then additionally fixed using special plastic fasteners with wide caps.

In the case where it is planned to install some kind of facing covering on top of the thermal insulation, a special frame of beams is prepared on the surface of the base, in the voids between which the insulating material you have chosen will subsequently be placed.

In the second case, in addition to the main frame, an additional row of beams (i.e., a second layer of sheathing) will be required, on which siding or lining panels will later be mounted. Upon completion of the entire complex of thermal insulation and finishing work, the previously prepared trench near the base is filled with a mixture of sand and soil.

Use of expanded clay

Expanded clay is known to absorb moisture well; however, under certain conditions it can also be used as a base insulator. These conditions require strict adherence to the following procedure for arranging a protective coating with your own hands:

First of all, a trench is dug from the outside (close to the foundation) to the entire depth of the foundation and about a meter wide.

Then roofing material is laid into it in such a way that its sheets cover not only the trench itself, but also the part of the house wall adjacent to it. The seams formed in this case are carefully glued, and the walls are treated with bitumen mastic.

After this, the trench is filled with expanded clay, which is well compacted when backfilled.

At the next stage of work, a sheathing is installed on the base plane, which in appearance should resemble wooden formwork, built around the entire perimeter of the house to a width of about half a meter.

Then a clay suspension previously diluted in water is poured onto the bottom of the resulting structure in a layer about 15 cm thick. After pouring it, the remaining free space is filled with the same expanded clay.

At the final stage of work, the formwork is closed with a lid, which is placed at an angle of at least 45 degrees. and protects the base from precipitation. The remaining part of the trench is covered with another layer of roofing felt, which is then filled with sand (the resulting multilayer coating can be used as a base for the subsequent arrangement of a concrete blind area).

Scheme for insulating the base with expanded clay

Important! Before backfilling, all wooden structural elements must be treated with antiseptics, which reliably protect them from destruction (mold formation). In this case, the part of the formwork that is placed below ground level and has direct contact with it must, in addition, be treated with a layer of bitumen mastic.

The foundation of any house must be strong, reliable, and durable. The microclimate inside the building will depend on these indicators. Statistics show that up to 20% of heat can be lost through an uninsulated foundation, so this issue must be approached with special care. Insulation of the basement of the house is provided even before construction, since it is necessary to select insulation and material for cladding. This article will discuss all the nuances regarding how to insulate the basement of a house with your own hands, without the involvement of professionals.

The design of the basement of a private house is such that all the beams of the first floor rest on it. The main part should be underground, so the outer part protrudes no more than half a meter. It is this part that, if insulated incorrectly or completely absent, can lead to large heat losses.

To avoid this, in modern construction they devote a lot of time to technology and the choice of material for insulating the foundation. This will minimize heat losses. When designing, in most cases, the process of insulation from the outside is considered, since this option is more acceptable and less labor-intensive.

Thanks to preliminary calculations and the purchase of all the material, the work on insulating the base can be carried out immediately and efficiently, so that later you do not have to spend money on alterations or completions.

To be confident in the final result, it is important to choose the right insulation, the range of which increases every year. If we talk about insulating the base, then it is worth highlighting several main options:

- Styrofoam;

- expanded polystyrene;

- priming;

- expanded clay

Each of the listed materials has its own advantages and features, as well as installation principles.

When choosing the material and technology for insulating the basement of a house, you need to take into account the planned budget, terrain, climate characteristics and other nuances.

Before you begin insulating the basement, you need to carefully prepare. In addition to purchasing the selected material and selecting the necessary tool and fasteners, it is important to prepare the surface. If you do not know how to correctly complete all the steps, then you should familiarize yourself with three main points, which will be enough for successful work.

At the first stage, it is necessary to go deeper, that is, to prepare a trench up to half a meter wide (the depth varies from person to person). The second stage involves completely cleaning the wall from soil, debris and even dust. At the third stage, the wall must be protected from moisture; for this, waterproofing is done (for example, with bitumen mastic).

If there are obvious irregularities on the wall, they must be eliminated before insulation begins. Waterproofing is applied in two layers, and the first must be completely dry before the second is applied to it.

This method is one of the most common and accessible, since it requires minimal time, effort and material. This is exactly how our ancestors insulated their houses from the outside. It was necessary to pour sand or soil into the prepared trench, but at the same time its height had to reach the floor. Among the advantages of this technology are the following:

- the waterproofing layer is fixed;

- availability;

- speed of work execution.

It is worth noting that soil and sand are ineffective as a heat insulator, so this option is used very rarely.

When choosing this method of insulation, you need to take into account that not only the basement will be underground, but also the basement, if there is one.

Due to its porosity, expanded clay is several times more effective insulation than sand, and since its cost is also low, it is widely used. For insulation, even a small layer of expanded clay is sufficient, since the thermal insulation properties of the material are very high.

Prepared expanded clay must be poured into the formwork if we are talking about insulating the base during the construction process. If insulation occurs after completion construction work, then the material is poured into the prepared trench. You should not mix expanded clay with concrete, as this mixture will not give the desired result.

Expanded clay is very often used for floor insulation, but in this case it is necessary to lay a layer on top mineral wool and waterproofing film, since the material is quite fragile.

Today, the most common materials for base insulation are polystyrene foam and expanded polystyrene; they differ in thickness, density and functionality. To thermally insulate the base with polystyrene foam, it is necessary to purchase a special adhesive solution, as well as carry out finishing work to protect the material from the influence of atmospheric phenomena.

The prepared adhesive mixture is applied to a sheet of foam plastic and then fixed to the wall. For greater reliability, experts recommend using plastic new settlers, the wide cap of which will securely fix the insulation. A plastic dowel is driven inside it.

To insulate the basement from the inside of the house, you cannot use the same materials that are used for walls - polystyrene foam and expanded polystyrene, since they are vapor-tight. The best option For insulation there will be mineral or basalt wool. In both the first and second cases, it is necessary to mount an additional wall (blende) from an aluminum profile and plasterboard sheets. The resulting space is filled with cotton wool and covered with plasterboard on top.

A fairly important issue in the process of insulating the basement inside the house is waterproofing, since without it any insulation will constantly get wet, which will lead to its rotting, mold and constant dampness in the room. The ideal solution would be to cover the wall with bitumen mastic in two layers, which will reliably protect it from moisture.

If it is not possible to purchase bitumen mastic, then you can use modern dry waterproofing mixtures, which should be accompanied by roll and coating materials.

In order for the basement insulation procedure to be as effective as possible, it is necessary to carry out all work at a temperature not lower than +5° C. Therefore, such work is carried out from mid-spring to early autumn. If you carry out plastering at sub-zero temperatures, the layer will most likely freeze and will not hold up.

Before starting work on insulating the base, it is necessary to get rid of all types of deformations: cracks, crevices, holes, bumps and irregularities. Any type of plaster or modern solutions: gypsum or sand-cement will cope with this task.

When choosing mineral wool, you should use special slabs that are fixed using adhesive solutions. In this case, the glue is applied both to the insulation and to the base wall.

In any insulation, holes are made for communications in designated areas. This procedure will save time.

At each stage of insulating the base, it is necessary to constantly monitor the evenness of the resulting surface. To do this, use a wooden lath or a building level.

Regardless of the choice of material for insulating the basement of a private house, the final work is finishing. The finishing will reliably protect the material from mechanical stress, as well as the influence of precipitation.

Video

You can learn how to insulate the basement of a house with polystyrene foam from the video:

Many beginning builders, among those who are lucky enough to own their own country plot, and who want to carry out most of the work on their own, make many serious mistakes at first. And one of the quite common ones is ignoring the issues of reliable and insulated foundations.

The resulting “picture” is interesting - as a rule, everyone remembers the external design of the basement part of the wall. Without in any way belittling the importance of neat finishing, we agree that it will not subsequently determine the level of comfort of living in the house and the durability of the building’s structural elements, but the quality of hydro- and thermal insulation directly affects this. Therefore, let's look at a very important topic - complete insulation of the foundation base from the outside. By the way, some technologies for thermal insulation of this part of the foundation also require its finishing.

Why is it generally necessary to insulate the foundation, and the basement in particular?

From a layman's point of view, the very formulation of the problem may not seem entirely clear - what is the point of insulating the foundation? After all, for the most part it is not directly adjacent to residential premises, and, it would seem, cannot in any way influence the microclimate in them. And if basements are not created, or they do not require maintaining a certain level of temperature, then why even start one?

This is an extremely common misconception! The foundation, like other structural elements of a building, needs reliable insulation, and this need is caused by a number of reasons of various properties. And, probably, first of all, thermal insulation of the foundation is a task aimed at maximizing its strength and durability, on which, of course, the operational life of the building itself directly depends. Let's look point by point and start with the most common - strip foundation.

First of all, it must be said that truly high-quality thermal insulation should include comprehensive insulation of both the vertical walls of the foundation (basement) and the blind area around the perimeter of the building. Otherwise, talking about the effectiveness of such measures will be naive.

- Massive reinforced concrete foundation without thermal insulation, the outside will always be a powerful cold accumulator in winter, from which it will spread to adjacent building structures. It is clear that the floor level of the premises on the first floor, as a rule, is located above the plinth line, and the walls and ceilings have their own insulation. But such proximity always leads to excess heat loss and, accordingly, to completely unnecessary, extra costs for energy resources used for heating purposes. Practice shows that even just competent insulation of the foundation gives a significant, up to 20–25%, saving effect, all other conditions being equal.

1 – ground level;

2 – foundation base;

3 – basement part of the foundation;

4 – building wall;

5 – ceiling (floor) of the first floor;

6 – insulation of the external wall;

Of course, the scheme is not a dogma, and some variations are possible. So, in particular, the layer of horizontal insulation (under the blind area) can be located buried, down to the level of the sole. But even in this case, it must be laid so that there is no gap between it and the vertical thermal insulation of the foundation wall.

We understand the required thickness of insulation

It is probably clear that the thickness of the foundation insulation must obey certain rules. The same Penoplex boards are available in a wide range of thicknesses, and it will not be difficult to purchase required material for single-layer or, if necessary, even double-layer thermal insulation. But how to find the right thickness?

To do this, you can carry out certain thermal calculations using formulas or even just tabular data.

Vertical thermal insulation of the foundation

Let's start with the vertical layer of insulation. The calculation will be based on the following formula:

Rsum = hф/λф + hу/λу

Rsum– total heat transfer resistance (measured in m²×°K/W) that the building structure must have, in in this case – strip foundation. This is a normalized tabular value established Building codes and rules (SNiP) for all regions of Russia, depending on the characteristics of their climate. If you wish, you can find tables on the Internet for various areas; this parameter is probably known in all local construction or design organizations, but it will be even easier to take the value from the diagram map below.

Please note that for each region three values of this thermal resistance are indicated: for walls and enclosing structures, for coatings and for floors. In this case, we are interested in “for walls” - in the columns these are the top values, highlighted in purple.

hf And λf– parameters characterizing the thermal characteristics of the foundation tape itself: this is the thickness of the tape in meters ( hf) and the thermal conductivity coefficient of reinforced concrete is a tabular value.

hу And λу– similar parameters of the insulating layer.

This means that if the thermal conductivity coefficient of the selected insulation material is known, then it is easy to calculate its required thickness using simple arithmetic operations.

And in order not to force the reader to dive into independent calculations, we suggest using a special online calculator, which already contains all the thermal dependences and the necessary tabular values.