Find out what a transistor is. How to test a transistor with a multimeter: testing various types of devices. For what reason does the transistor not work?

Content:

The performance of radio engineering circuits largely depends on correctly completed assembly, as well as testing actions on its elements. Many radio amateurs often assemble circuits on their own and the question arises: how to check a transistor with a multimeter, especially when it is already installed and the functionality of the assembled device is being configured? In order to configure radio circuits, you need to understand what a transistor is and how it works. Let's consider the issues of circuit testing and transistor testing.

Types of transistors

For a specialist, checking a transistor begins with identifying the element by its type; this action is performed in the case of repair work, as well as in the process of testing purchased circuits for operability.

A semiconductor triode, which is made of a material with semiconducting properties, having three terminals, when it can control a large current at the output of the circuit from a small input signal in a circuit, is called a TRANSISTOR. It is used in energy generation devices, in switching circuits, in amplifying devices to amplify electrical signals, as well as convert them.

In radio engineering, there are two types of commonly encountered transistors - field-effect and bipolar radio elements.

Main types:

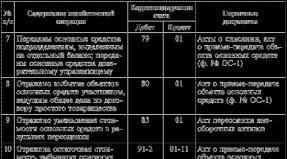

Bipolar transistors are characterized by the creation of an amount of electric current at the output by electrons and holes, in other words, by both sign carriers. Field options use only one carrier to generate current at the device output. Using a multimeter test, you can check the performance of a bipolar element, which has three terminals and two p-n junctions. The operation of this element in the circuit involves the use of electron and hole charges; through the control current, the current flowing through the transistor is controlled. A bipolar transistor has semiconductor layers N-P-N and P-N-P and two p-n junctions; the layers are connected using contacts: the middle layer is the base, the two outer layers are the emitter and collector. In radio engineering, a pin with an arrow in an element on a diagram indicates the emitter and the direction of current flow.

Transistors of different types have different functions of charge carriers; they are more common N-P-N types, which have the best characteristics and parameters. Due to their mobility, electrons play the “first role” in elements; the operation of the device improves with an increase in the area of the collector junction.

How to test a transistor with a multimeter

Experts offer step-by-step steps on how to check the functionality of a radio element:

- we determine the structure of the semiconductor device using the emitter arrow;

- if the arrow points towards the base, the transition is P-N-P;

- when the arrow is directed from the base of the device - N-P-N conductivity.

Different types according to conductivity:

After determining the conductivity of a circuit element, we perform the following steps sequentially:

- we measure the presence of reverse resistance - apply the multimeter probe (+) to the base contact;

- We check the transition on the emitter - we apply the probe of the device (-) to the emitter contact.

The result of these manipulations will be value = 1, when the element is operational, then we check the direct resistance:

- We transfer the multimeter probe (-) from the emitter to the base;

- We apply the positive probe (+) to the collector and emitter in turn.

In a working transistor, the multimeter during these manipulations should show a resistance of 500 to 1000 Ohms, which indicates the integrity of the component.

When the question arises of how to check a transistor with a multimeter, experts suggest that radio amateurs determine the base, since it is often with it that difficulties in determining occur. To do this you need to do the following:

- We connect the black (-) probe to the first contact, and the positive one to the second;

- then we measure - black on the first contact (+) on the third contact;

- when the voltage on the display drops, it means that the emitter-base or collector-base pair has been detected;

- the next step is to determine the second pair, and the common contact is the base.

How can you verify that the transistor in the circuit is working?

It is difficult to check the operation of the elements every time by desoldering them from the circuit; in some cases this is difficult to do; for this reason, experts recommend using a probe that will help check the serviceability of the transistor.

This device is a blocking generator, checking the NPN transistor means it performs the task of the active device, indicators in a complex circuit show whether the semiconductor device is broken or not. There are many solutions for making probes, their options are well presented on the Internet. To ring the triode, you need to do the following step by step:

- We check the operation of the probe on a working transistor, there should be generation, then we continue to test the probe. If there is no generation, you need to swap the terminals of the windings.

- We pay attention to L1, the lamp that works to open the probes, it should be on, if the lamp does not respond, we try to swap the leads on the transformer windings.

- When the probe is checked, we begin working with the circuit - we check the pnp transistor in the circuit without desoldering it on the board, connect the probe to the terminals, and set the transition switch to one of the modes - P-N-P or N-P-N, turn on the power.

When L1 lights up, this means that the element is operational, if L2 lights up, then this is evidence of some kind of malfunction, perhaps one of the transitions is broken. If neither L1 nor L2 is lit, this means that the semiconductor device is not working.

When it is not possible to check a transistor with a multimeter, do not despair, there are probes that do not require preliminary adjustment, they have more simple circuit- this is an ordinary battery and a light bulb, you can use an LED. When by alternately touching the contacts of the transistor with the probes of a simple device, a pair is determined in which the LED lights up, but in the other version does not, the radio element (transistor) is working. This method of dialing the circuit is recommended on boards where there is no power current. You can check it with a tester.

For what reason does the transistor not work?

The most likely reasons, according to experts, for the failure of the triode in the circuit are as follows:

- when one of the transitions disappears (breaks);

- transition breakdown;

- breakdown in one of the sections of the emitter or collector;

- loss of power by a semiconductor device during operation;

- visual damage to the transistor terminals.

Signs by which you can visually determine the breakdown of a triode in a circuit: darkening or change in the original color of the semiconductor device, a change in its “bulge” shape, the presence of a black spot.

How to test a composite transistor

A Darlington device is a compound transistor that can combine several bipolar semiconductor devices in its circuit, which allows the circuit to solve problems such as doubling or greater current. Typically, composite transistors are used in circuits in which large current flows: stabilizers, power amplifiers. These devices require high level input impedance, in other words, complex resistance in full. You can check a composite transistor in the same way as N-P-N element- use a multimeter, like a regular bipolar device.

Conclusion

Before understanding the question of how to check the operation of a triode, it is necessary, according to experts, to understand how it is structured and how it should work. The next step is to take a responsible approach to choosing a method for checking the functionality of the transistor with a multimeter. In addition to identifying the faulty element in the circuit, you need to understand the reason for the occurrence of this fault; it is not enough to replace the transistor, you need to eradicate the reason that led it to an inoperative state.

Experienced electricians and electronics engineers know that there are special probes to fully test transistors.

Using them, you can not only check the serviceability of the latter, but also its gain - h21e.

The need for a probe

A probe is a really necessary device, but if you just need to check the transistor for serviceability, it is quite suitable.

Transistor device

Before you start testing, you need to understand what a transistor is.

It has three terminals that form diodes (semiconductors) between them.

Each pin has its own name: collector, emitter and base. First two conclusions p-n transitions are connected in the base.

One pn junction between base and collector forms one diode, second p-n the junction between base and emitter forms a second diode.

Both diodes are connected in a circuit back-to-back through the base, and this entire circuit is a transistor.

We are looking for the base, emitter and collector of the transistor

How to immediately find a collector.

To immediately find the collector, you need to find out what power the transistor is in front of you, and they come in medium power, low power and high power.

Medium power and powerful transistors get very hot, so heat needs to be removed from them.

This is done using a special cooling radiator, and heat is removed through the collector terminal, which in these types of transistors is located in the middle and connected directly to the housing.

The result is the following heat transfer scheme: collector output – housing – cooling radiator.

If the collector is identified, then determining other conclusions will not be difficult.

There are cases that greatly simplify the search, this is when the device already has the necessary symbols, as shown below.

We make the necessary measurements of forward and reverse resistance.

However, all the same, the three legs sticking out in the transistor can throw many novice electronics engineers into a stupor.

How can you find the base, emitter and collector?

You can’t do this without a multimeter or just an ohmmeter.

So, let's start the search. First we need to find a base.

We take the device and make the necessary measurements of the resistance on the legs of the transistor.

We take the positive probe and connect it to the right terminal. We alternately bring the negative probe to the middle and then to the left terminals.

Between right and middle, for example, we showed 1 (infinity), and between right and left 816 Ohm.

These readings don't tell us anything yet. Let's take further measurements.

Now we move to the left, bring the positive probe to the middle terminal, and successively touch the negative probe to the left and right terminals.

Again the middle one - the right one shows infinity (1), and the middle left one 807 Ohm.

This also doesn’t tell us anything. Let's measure further.

Now we move even more to the left, we bring the positive probe to the leftmost terminal, and the negative one sequentially to the right and middle.

If in both cases the resistance shows infinity (1), then this means that the left terminal is the base.

But where the emitter and collector (middle and right terminals) will still need to be found.

Now you need to measure direct resistance. To do this, now we do everything in reverse, the negative probe to the base (left terminal), and alternately connect the positive one to the right and middle terminals.

Remember one important point, p-n resistance The base-emitter junction is always larger than the base-collector p-n junction.

As a result of measurements, it was found that the resistance of the base (left terminal) - right terminal is equal 816 Ohm, and the base resistance is the middle terminal 807 Ohm.

This means that the right pin is the emitter, and the middle pin is the collector.

So, the search for base, emitter and collector is completed.

How to check a transistor for serviceability

To check the transistor with a multimeter for serviceability, it will be enough to measure the reverse and forward resistance of two semiconductors (diodes), which we will now do.

There are usually two junction structures in a transistor p-n-p And n-p-n.

P-n-p– this is an emitter junction, you can determine this by the arrow that points to the base.

The arrow that goes from the base indicates that this is an n-p-n junction.

The PnP junction can be opened using a negative voltage applied to the base.

We set the multimeter operating mode switch to the resistance measurement position at the “ 200 ».

We connect the black negative wire to the base terminal, and connect the red positive wire in turn to the emitter and collector terminals.

Those. We check the functionality of the emitter and collector junctions.

Multimeter readings range from 0,5 before 1.2 kOhm They will tell you that the diodes are intact.

Now we swap the contacts, connect the positive wire to the base, and alternately connect the negative wire to the emitter and collector terminals.

There is no need to change the multimeter settings.

The last reading should be much higher than the previous one. If everything is normal, then you will see the number “1” on the device display.

This suggests that the resistance is very high, the device cannot display data above 2000 Ohms, and the diode junctions are intact.

Advantage this method The point is that the transistor can be checked directly on the device without unsoldering it from there.

Although there are still transistors where low-resistance resistors are soldered into the p-n junctions, the presence of which may not allow for correct resistance measurements; it can be small, both at the emitter and collector junctions.

IN in this case The leads will need to be unsoldered and measurements taken again.

Signs of a transistor malfunction

As noted above, if the measurements of direct resistance (black minus on the base, and plus alternately on the collector and emitter) and reverse (red plus on the base, and black minus alternately on the collector and emitter) do not correspond to the above indicators, then the transistor has failed .

Another sign of a malfunction is when the resistance of the pn junctions in at least one measurement is equal to or close to zero.

This indicates that the diode is broken and the transistor itself is faulty. Using the recommendations given above, you can easily check the transistor with a multimeter for serviceability.

Semiconductor elements such as transistors are an integral part of almost all electronic circuits- from radio receivers to motherboards of highly complex computer centers. Checking this element for operability is an operation that any person involved in repairs in one way or another must be able to perform. electronic boards, whether he is a professional repairman or an amateur.

To carry out this operation, you can use a special transistor tester, but if it is not at hand, or there are doubts about its reliability, you can use the most ordinary multimeter. Even those models that do not have a special socket for testing bipolar or field-effect transistors can be used for accurate testing. To do this, the multimeter is set to maximum resistance mode, or “continuity” mode, if there is one.

General verification algorithm

How to test a transistor with a multimeter? In general, the algorithm looks like this:

Further verification steps will depend on what type of element needs to be checked. Basically, semiconductor elements of two types are used in electronics - bipolar and field-field.

Bipolar

How to test a bipolar transistor with a multimeter? First of all, you need to find out which of the two subtypes - npn or pnp it belongs to. To do this, let’s remember what a bipolar transistor is.

This is a semiconductor element in which the so-called npn or pnp junction is implemented. N-p-n is the transition “electron - hole - electron”, p-n-p, respectively, on the contrary, “hole - electron - hole”. Structurally, it consists of three parts - emitter, collector and base. In fact, a bipolar is two conjugated ordinary diodes, in which the base is the common connection point.

This is a semiconductor element in which the so-called npn or pnp junction is implemented. N-p-n is the transition “electron - hole - electron”, p-n-p, respectively, on the contrary, “hole - electron - hole”. Structurally, it consists of three parts - emitter, collector and base. In fact, a bipolar is two conjugated ordinary diodes, in which the base is the common connection point.

In the pnp circuit, the transistor differs from its npn counterpart in the direction of the arrow in the circle - the arrow of the emitter junction. U pnp circuits it is directed towards the base, for n-p-n it is the opposite.

You need to know this difference to check the bipolar transistor. A Pnp circuit is opened by applying a negative voltage to the base, and an Npn one by applying a positive voltage. But before this, it is necessary to find out which of the contacts of the transistor being tested is the base, which is the emitter, and which is the collector.

Please note that using the method described below to determine which of the contacts is the base, and which are the emitter and collector, it is possible only for a working element. The very fact that the transistor has passed this test indicates that it is most likely working.

The instructions here could be as follows:

- the red (positive) probe is connected to the first terminal that comes across, for example the left one, the black (negative) probe is alternately touched to the central and right ones. Fix the value “1” on the central one, and 816 Ohms, for example, on the right;

- The red probe of the multimeter is short-circuited with the central contact, the black one - alternately with the side ones. The device displays “1” on the left and some value, say 807, on the right;

- when the red probe of the multimeter contacts the right terminal, and the black probe contacts the left and center, we get “1” in both cases. This means that the base is defined - this is the right contact of the transistor. And the transistor itself is PNP type.

In principle, this is enough to say that the transistor is working. Now, to check its structure and the specific location of the emitter and collector, we short-circuit the black (negative) probe of the multimeter with the base, and the red one in turn with the left and center contacts.

The contact that gives a lower resistance value will be a collector contact (in our case, 807 Ohms). The larger one - 816 Ohms - is the emitter one.

Testing an NPN type transistor occurs in the same way, only the positive contact is applied to the base.

This is the way p-n checks transitions between base and collector and base and emitter. The multimeter readings may vary depending on the type of transistor, but will always be within the range of 500-1200 Ohms. To complete the test, touch the emitter and collector probes. A working element will produce infinitely high resistance, regardless of its type, no matter how you change the polarity. If the value on the screen differs from “1”, one of the transitions is broken, the part is unusable.

Testing without soldering

If you are not sure that this particular transistor needs to be checked, you can measure its parameters on the board without desoldering. But at the same time, the multimeter should show values in the range of 500-1200 Ohms. If they are measured in units or even tens of Ohms, the circuit is shunted with low-resistance resistors. For an accurate check, the transistor will have to be unsoldered.

Field

A field-effect transistor, also known as a mosfet, differs from a bipolar transistor in that either only a positive charge or only a negative charge (“hole” or electron) can flow through it. Its contacts have a different meaning - gate, drain, source.

How to check field-effect transistor multimeter? The testing method is almost the same as in the previous case, but first, in order to avoid the element failure, it is necessary to remove the charge static electricity, since the field worker is very sensitive to statics. Use an antistatic wrist strap, or simply touch your hand to a grounded metal part, such as a cabinet frame.

Field devices always have a small conductivity between the drain and the source, which is detected on the multimeter screen as a resistance of the order of 400-700 Ohms. If you reverse the polarity, the resistance will change slightly, increasing or falling by 40-60 ohms. Before this, it is necessary to short-circuit the source and drain together in order to “zero” the capacitances of the junctions.

Field devices always have a small conductivity between the drain and the source, which is detected on the multimeter screen as a resistance of the order of 400-700 Ohms. If you reverse the polarity, the resistance will change slightly, increasing or falling by 40-60 ohms. Before this, it is necessary to short-circuit the source and drain together in order to “zero” the capacitances of the junctions.

If, when tested with a multimeter, an infinitely large resistance is detected between the source and drain, the field effect transistor is faulty.

Conductivity will also be detected between source and gate or drain and gate, but only in one direction. A plus applied to the gate, and a minus to the source, will cause the transition to open and, accordingly, the value on the screen will be in the range of 400-700 Ohms. The reverse circuit - plus to the source, minus to the gate - for a working field operator will give “1”, that is. very high resistance.

Checking the drain-gate line is similar. If the source-gate or drain-gate line has conductivity in both directions, this means that the field-effect transistor is broken.

In conclusion, we need to say a few words about the composite type. A compound transistor is an element that combines two ordinary bipolar transistors (sometimes three or more). Testing with a multimeter is carried out similarly to the methodology for a simple “bipolar”.

Transistors have to be checked quite often. Even if you have in your hands a obviously new one that has never been soldered, then before installing it in the circuit it is better to check it. There are often cases when transistors purchased on the radio market turned out to be unusable, and not even just one copy, but a whole batch of 50 - 100 pieces. Most often this happens with powerful transistors domestic production, less often with imported ones.

Sometimes design descriptions provide some requirements for transistors, for example, a recommended transmission ratio. For these purposes, there are various transistor testers, quite complex in design and measuring almost all the parameters that are given in reference books. But more often you have to check transistors according to the “pass or fail” principle. It is these verification methods that will be discussed in this article.

Often in a home laboratory there are used transistors on hand, once obtained from some old circuit boards. In this case, 100% “input control” is necessary: it is much easier to immediately identify an unusable transistor than to later look for it in a non-working design.

Although many authors of modern books and articles strongly discourage the use of parts of unknown origin, quite often this recommendation has to be violated. After all, it’s not always possible to go to a store and buy the part you need. Due to such circumstances, it is necessary to check each transistor, resistor, capacitor or diode. Next we will mainly talk about checking transistors.

Testing transistors in amateur conditions is usually carried out using an old analog avometer.

Checking transistors with a multimeter

Most modern radio amateurs are familiar with universal device called a multimeter. With its help, it is possible to measure direct and alternating voltages and currents, as well as conductor resistance DC. One of the resistance measurement limits is intended for “continuity testing” of semiconductors. As a rule, a symbol of a diode and a sounding speaker is drawn near the switch in this position.

Before checking transistors or diodes, you should make sure that the device itself is working properly. First of all, look at the battery charge indicator; if necessary, replace the battery immediately. When you turn on the multimeter in the “dialing” mode of semiconductors, a unit should appear in the most significant digit on the indicator screen.

Then check the serviceability by connecting them together: zeros will appear on the indicator and a beep will sound. This is not a vain warning, since wire breaks in Chinese probes are quite common, and this should not be forgotten.

For radio amateurs and professional electronics engineers of the older generation, this gesture (checking the probes) is performed mechanically, because when using a dial tester, each time you switched to the resistance measurement mode, you had to set the arrow to the zero scale division.

After these checks have been completed, you can begin checking semiconductors - diodes and transistors. Pay attention to the polarity of the voltage on the probes. The negative pole is on the socket labeled “COM” (common), and the socket labeled VΩmA is positive. In order not to forget about this during the measurement process, a red probe should be inserted into this socket.

Figure 1. Multimeter

This remark is not as idle as it might seem at first glance. The fact is that with dial avometers (AmperVoltOhmmeter) in resistance measurement mode, the positive pole of the measuring voltage is located on the socket marked “minus” or “common”, well, exactly the opposite, compared to a digital multimeter. Although digital multimeters are now more commonly used, pointer testers are still used and in some cases allow one to obtain more reliable results. This will be discussed below.

Figure 2. Pointer avometer

What does the multimeter show in the “dialing” mode?

Diode check

The simplest semiconductor element is one that contains only one P-N junction. The main property of a diode is one-way conductivity. Therefore, if the positive pole of the multimeter (red probe) is connected to the anode of the diode, then numbers will appear on the indicator showing the forward voltage at the P-N junction in millivolts.

Figure 3.

For silicon diodes this will be about 650 - 800 mV, and for germanium diodes it will be about 180 - 300, as shown in Figures 4 and 5. Thus, from the readings of the device you can determine semiconductor material, from which the diode is made. It should be noted that these figures depend not only on the specific diode or transistor, but also on the temperature, with an increase of 1 degree, the forward voltage drops by approximately 2 millivolts. This parameter is called the voltage temperature coefficient.

Figure 4.

Figure 5.

If, after this check, the multimeter probes are connected in reverse polarity, then the device indicator will show a unit in the most significant digit. Such results will occur if the diode turns out to be serviceable. This is actually the whole technique for testing semiconductors: in the forward direction the resistance is negligible, but in the reverse direction it is almost infinite.

If the diode is “broken” (the anode and cathode are short-circuited), then most likely an audible signal will be heard, and in both directions. If the diode is “broken,” no matter how you change the polarity of connecting the probes, the indicator will still show one.

Transistor testing

Unlike diodes, transistors have two P-N transition, and have P-N-P and N-P-N structures, the latter being much more common. In terms of testing with a multimeter, a transistor can be considered as two diodes connected back-to-back in series, as shown in Figure 6. Therefore, testing transistors comes down to “testing” the base-collector and base-emitter transitions in the forward and reverse directions.

Consequently, everything that was said just above about checking the diode is completely true for studying transistor transitions. Even the multimeter readings will be the same as for the diode.

Figure 6.

Figure 7 shows the polarity of turning on the device in the forward direction for “diagnosis” of the base-emitter transition of transistors N-P-N structures: The positive probe of the multimeter is connected to the base terminal. To measure the base-collector transition, the negative terminal of the device should be connected to the collector terminal. In this case, the number on the display was obtained by testing the base-emitter transition of the KT3102A transistor.

Figure 7.

If the transistor turns out to be of a P-N-P structure, then the negative (black) probe of the device should be connected to the base of the transistor.

At the same time, you should “ring” the collector-emitter section. A working transistor has almost infinite resistance, which is symbolized by one in the most significant digit of the indicator.

Sometimes it happens that the collector-emitter junction is broken, as evidenced by the sound signal of the multimeter, although the base-emitter and base-collector junctions “ring” as if normal!

It is performed in the same way as with a digital multimeter, but one should not forget that the polarity in the ohmmeter mode is reverse compared to the DC voltage measurement mode. In order not to forget this during the measurement process, the red probe of the device should be plugged into the socket with the “-” sign, as shown in Figure 2.

Avometers, unlike digital multimeters, do not have a semiconductor dialing mode, so in this regard their readings differ markedly depending on the specific model. Here you already have to rely on your own experience accumulated in the process of working with the device. Figure 8 shows the measurement results using the TL4-M tester.

Figure 8.

The figure shows that measurements are carried out at the limit of *1Ω. In this case, it is better to focus on the readings not on the scale for measuring resistance, but on the upper uniform scale. It can be seen that the arrow is in the area of number 4. If measurements are made at the limit of *1000Ω, then the arrow will be between numbers 8 and 9.

Compared to a digital multimeter, an avometer allows you to more accurately determine the resistance of the base-emitter section if this section is shunted with a low-resistance resistor (R2_32), as shown in Figure 9. This is a fragment of the output stage circuit of an ALTO amplifier.

Figure 9.

All attempts to measure the resistance of the base-emitter section using a multimeter lead to the sound of the speaker (short circuit), since a resistance of 22Ω is perceived by the multimeter as a short circuit. An analog tester at the measurement limit of *1Ω shows some difference when measuring the base-emitter junction in the opposite direction.

Another pleasant nuance when using a dial tester can be found if you take measurements at the limit of *1000Ω. When connecting the probes, of course, observing the polarity (for a transistor of the N-P-N structure, the positive terminal of the device is on the collector, minus on the emitter), the arrow of the device will not move, remaining at the infinity scale mark.

If you drool now forefinger, as if to check the heating of the iron, and close the base and collector terminals with this finger, then the arrow of the device will move, indicating a decrease in the resistance of the emitter-collector section (the transistor will open slightly). In some cases, this technique allows you to check the transistor without removing it from the circuit.

This method is most effective when testing composite transistors, for example KT 972, KT973, etc. We should not just forget that composite transistors often have protective diodes connected parallel to the collector-emitter junction, and in reverse polarity. If the transistor is an N-P-N structure, then the cathode of the protective diode is connected to its collector. An inductive load, for example, relay windings, can be connected to such transistors. Internal organization composite transistor is shown in Figure 10.

Figure 10.

Transistor testing is important point in electronics and radio engineering. Try to figure out on your own how to test a transistor with a multimeter without unsoldering it. This is a fairly simple procedure that can be followed different ways. Most practical option- checking the transistor with a multimeter. It is this method that will be discussed in this article.

General information

Today there are two types of transistors - bipolar and field-effect. In the first, the output current is created with the participation of both charges in the form of holes and electrons, while in the other version only one of the carriers participates.

Checking the bipolar transistor

The specified procedure for bipolar transistors It starts with proper setup of the device. The device is switched to semiconductor testing mode; one should appear on the display. The terminals are connected in a similar way to the resistance measurement mode. A black wire is connected to the COM port, and a red wire is connected to the output to measure voltage, resistance and frequency. If the multimeter does not have a corresponding mode, then the process should be carried out in resistance measurement mode when set to maximum.

It is also important that the multimeter battery is fully charged and the probes are in good working order. When connecting the tips, serviceability is indicated by the squeak of the device and zeros on the screen. The procedure in this case follows the following steps:

As a result, there is no need to solder the element to ensure its serviceability. If you want to use for checking light bulbs and other elements, it is not recommended to do this, since there is a risk of permanently damaging the bipolar transistor.

Field device test

Procedure for such elements similar to bipolar. However, there are some peculiarities here:

Due to these points, it is possible to carry out a high-quality check of field devices without involving desoldering. If you have a composite device, then the test is similar to the procedure for bipolar devices.

Advantage of the method

Testing a transistor using a multimeter is advantageous in that there is no need to solder the element, and it is quite accurate. The methodology for testing bipolar and field devices is similar, but it is necessary to take into account a number of points and nuances that help improve the methodology. Proper setting of the multimeter and the ability to work with various elements will allow you to perform the most accurate and high-quality check of the serviceability of devices of any type.

Testing a transistor using a multimeter is advantageous in that there is no need to solder the element, and it is quite accurate. The methodology for testing bipolar and field devices is similar, but it is necessary to take into account a number of points and nuances that help improve the methodology. Proper setting of the multimeter and the ability to work with various elements will allow you to perform the most accurate and high-quality check of the serviceability of devices of any type.