Thermal insulation. Floor insulation

Floor insulation

Your home, your world. This space should be comfortable and cozy, protected from external adverse influences, and therefore insulated. High-quality thermal insulation of premises is one of the main conditions for a good microclimate in the house.

Thermal insulation is all the more important because many different heaters have been invented to combat the cold - from a fire in a cave to a nuclear power plant. But in order to warm the home, it is not necessary to use powerful heating devices, you can learn not to lose the accumulated heat by isolating the house from the cold. Thermal insulation should provide a certain temperature regime in the room, namely room temperature, that is, a certain range that is comfortable for human life. For each of us, you can determine both the upper and lower values of this parameter, but the range of 18-22 ° C is considered the optimal temperature.

General requirements for thermal insulation

thermal insulation is a set of measures to protect buildings from unwanted heat exchange with the environment. The main way to reduce heat loss is to increase the thermal resistance of enclosing structures with the help of heat-insulating materials.

The main indicators of such materials: thermal conductivity, sound insulation characteristics, fire safety, compressive strength; humidity and water absorption; vapor and air permeability, fire resistance. The most important indicator is the coefficient of thermal conductivity; the smaller it is, the better the thermal insulation qualities of the material. This value is not constant, it can change under different operating modes.

Thermal insulation of premises has a number of advantages. In particular, the rooms of the house acquire a stable microclimate with a stable temperature and humidity, not freezing in severe frosts and not overheating in sweltering heat. In addition, thermal insulation measures, as mentioned above, lead to a reduction in heating costs. And this, in turn, reduces the cost of natural resources and emissions of harmful substances - nowadays it is fashionable to take care of the environment, but this is the case when it is worth following the fashion. Yes, and life in a warm, but ventilated room is healthier. Note that thermal insulation measures significantly increase the life of building structures.

Why do you need floor insulation?

First, let's clarify that the floor is a building structure on which the life of people is carried out and on the state of which the health of people and the quality of products largely depend. Floors play a major role in keeping the heat inside buildings, and without thermal insulation, heat loss in a home can be as high as one-fifth of the total heat loss.

Insulated floors not only retain heat and reduce heating costs, but also provide comfortable living for a person. Moreover, the warm floor is most acceptable. Everyone knows the old saying: "Keep your head in the cold, and your feet warm."

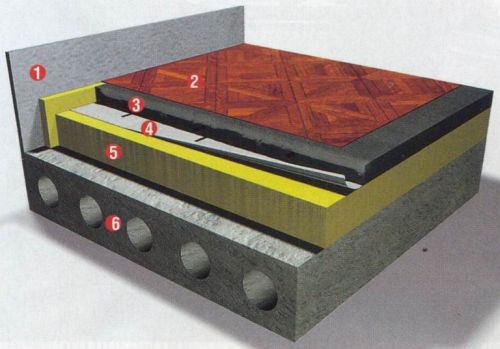

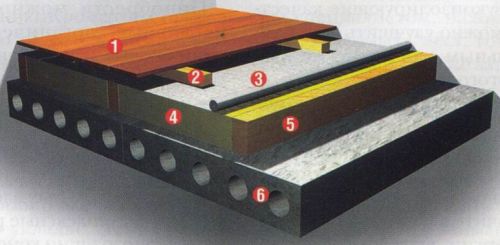

1. Wall. 2. Floor covering. 3. Cement screed. 4. Waterproofing layer. 5. Thermal insulation. 6. Bearing reinforced concrete floor, gravel preparation

It should be noted that the materials used for floor insulation are subjected to increased loads. Because of this, among the requirements for them, first of all, it is necessary to name high compressive strength and a small degree of deformation during compression. Other important characteristics of the heat-insulating material, which make it possible to minimize the thickness of building structures, are low thermal conductivity and the ability to maintain heat-insulating qualities for an almost unlimited time even when exposed to moisture and mechanical stress. The thermal insulation material must be user-friendly, i.e. easy to cut, simple and fast to install with little waste. This minimizes the cost of thermal insulation work.

1. Floor covering. 2. Lathing. 3. Waterproofing. 4. Thermal insulation. 5. Lags. 6. Bearing reinforced concrete floor, gravel preparation

Laying thermal insulation, especially for the floor, located above a cold or relatively cold room, for example, above a basement or near the outer wall of a building, it is better to do it from the underside of the ceiling. Then the material laid on the cold side will prevent the formation of condensate and reduce sudden changes in temperature inside the building. If this cannot be done, then the insulation layer is laid on the upper side of the ceiling, and the soundproofing qualities can be improved with an additional layer of the same or another material.

Floor insulation is also effective when installing water or cable heating systems, that is, a “warm floor”. Without thermal insulation, a significant part of the thermal energy released by the heating elements of the "warm floor" is lost through the floors. And the use of thermal insulation allows almost all energy to be spent for its intended purpose.

Underfloor heating systems require surface leveling and thermal insulation from the ceiling so that thermal energy is not lost

Thermal insulation materials

The market for thermal insulation materials is diverse and large-scale, which is primarily due to the high demand for both new construction and for the repair and reconstruction of existing housing. Contribute to interest in thermal insulation and rapidly rising energy prices.

You can buy mineral, organic and cork materials made by both global and domestic manufacturers. We offer both individual materials designed for thermal insulation of building elements, as well as complex solutions for thermal insulation of structures and buildings as a whole.

Range of materials for floor insulation, wide. These are mineral wool based on basalt and fiberglass, polystyrene foam, polyurethane foam, cork. For each of these materials, manufacturers have developed constructive flooring schemes.

Mineral wool

Mineral wool is produced on a stone or fiberglass basis. "Stone" mineral wool has a high heat and sound insulating ability, good water-repellent properties and fire resistance, resistance to mechanical stress. For floor insulation, mineral wool is available in the form of a flexible mat or a solid slab.

A flexible mat is made of hydrophobized mineral wool, covering the mat on one side with perforated kraft paper; it is necessary to lay the material so that the side covered with kraft paper (laminated) is directed towards the insulated room, that is, up.

Plates are most often used for warming the floors of the first floors in rooms without basements.. They are also made from hydrophobized mineral wool, and the side with greater rigidity is marked with a blue stripe. When laying the boards, the side marked with the blue stripe must be on top. A distinctive feature of mineral wool is not only high thermal resistance, but also good soundproofing ability.

Glass wool is a mineral fiber, for the production of which the same raw materials are used as for the production of ordinary glass, or waste from the glass industry. Glass wool products have increased elasticity and strength, vibration resistance, therefore they are also very good sound insulators. In addition, they are non-flammable and environmentally friendly. Plates, semi-rigid or rigid, as well as mats are produced from glass wool.

Mineral wool slabs or mats laid on the floor base must be waterproofed, it is desirable to strengthen with a reinforcing layer, and then lay the finish coat.

Mineral wool slabs are laid between the floor joists

And then they are covered from above with a vapor barrier with a bend on the walls

Styrofoam

This material for thermal insulation has been known and used for a long time, but now it is already a different, seriously improved material. It can be extruded and foamed polystyrene foam, the first option can be called the most promising. Thanks to its closed cell structure, this material has a long service life and provides an effective and economical solution to the problem of thermal insulation of floors.

With this structure, extruded polystyrene boards do not absorb moisture and have very high flexural and compressive strength. Therefore, they can be laid under waterproofing membranes on a rigid base of coarse gravel, with a leveling layer of sand, providing thermal insulation of the basement of the building in such a structure. For thermal insulation of the first floor, it is best to lay polystyrene foam boards under the floor structures. Being on the cold side, thermal insulation eliminates the formation of condensate, increases the degree of utilization of the heat capacity of the floor slabs and reduces sudden temperature changes inside the house. If it is not possible to lay a heat-insulating layer on the underside of the floors of intermediate floors, then the heat-insulation is placed on top.

Also, extruded polystyrene foam boards can be embedded in the formwork, because due to their corrugated surface they have a high degree of adhesion (adhesion) to concrete. If the concrete is sufficiently well compacted, the adhesive force is so strong that no additional parts and fixtures are required to fix the thermal insulation boards. The thermally insulated surface can be plastered or covered with some kind of facing material.

polyurethane foam

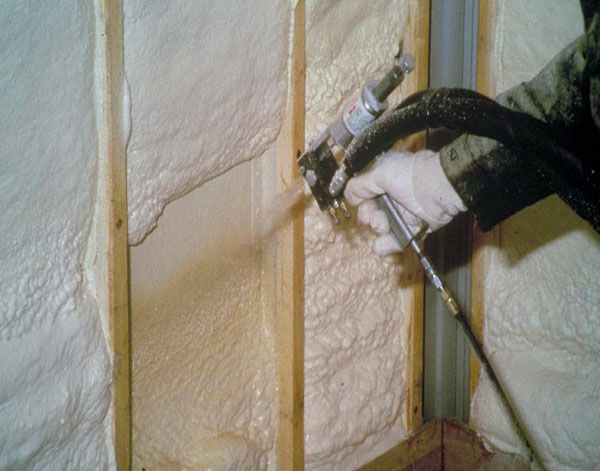

These lightweight and durable materials have a peculiar structure similar to frozen foam. They have excellent adhesive qualities, easily sticking to surfaces of any shape. Polyurethane foam is sprayed on almost any material - wood, glass, metal, concrete, brick, paint - regardless of the surface configuration. As a result, there is no need for special insulation fasteners. In addition, polyurethane foam coating is inert to acidic and alkaline environments and can work in the ground.

For floor insulation, polyurethane foam is applied by spraying. The advantages of this method: the complete absence of cracks, very low vapor permeability, high thermal insulation properties and the minimum period of work. At the same time, a very long service life, up to 50 years. Polyurethane foam can also be used in combination with other materials, in particular mineral wool, laid on top of it. Thus, the lower layer of polyurethane foam provides gapless insulation, which in turn is a vapor barrier for the upper layer of mineral wool. It should be noted that when insulated with polyurethane foam, high sound insulation performance is also achieved. In addition, when installing thermal insulation of "wet" rooms (pools, bathrooms, etc.), insulation with polyurethane foam does not require laying a protective waterproofing coating.

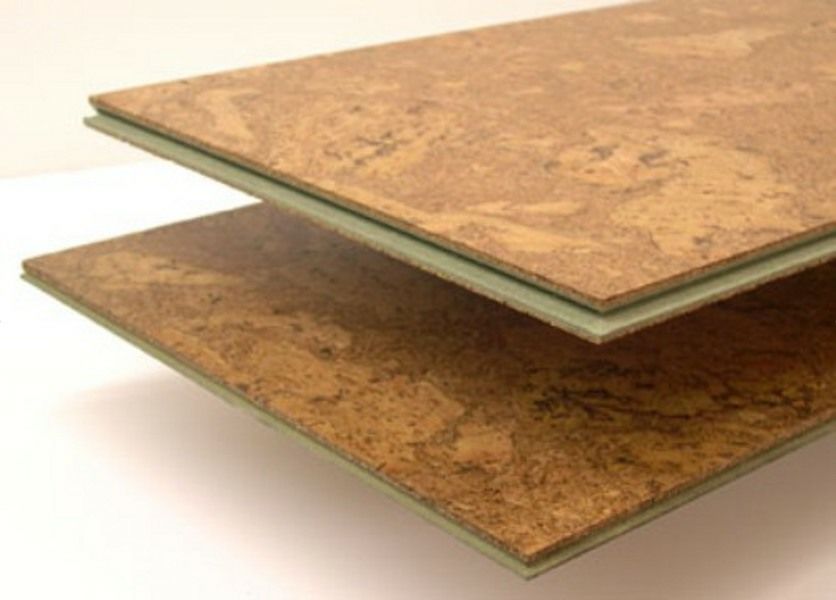

Cork insulation boards are natural materials made from cork oak bark. This material is lightweight, durable in compression and bending, not shrinking and rotting. In addition, cork is easy to cut, chemically inert, and durable. Although it is not non-combustible, the ignition threshold of the cork is nevertheless quite high, and when burned, it does not emit harmful substances.

Cork slabs are easy to install, easy to cut for a precise fit when installed, and quite versatile. Cork is available in slabs or rolls.

Choose your insulation method

Among these materials, each of you is free to choose the most suitable for your conditions, affordable and easy to install. It is advisable, of course, to consult with a specialist. The whole process of thermal insulation can take place in two ways. One option involves setting a specific task: warming a cold floor, for example, on a balcony or above a basement. Based on prices and characteristics, the material is determined and its installation is carried out.

The second option provides for a more serious preliminary calculation, a qualitative study of the apartment by a specialist, finding “cold” places, heat leakage points, etc. Only then, on the basis of these data, is the determination of materials, their parameters, size. Finally, styling. At the same time, it is important not to make a mistake with the choice of a company that will perform these works. Pay attention to the period of work of the company, and, accordingly, to the experience, availability of a license and warranty obligations for the work performed.