Dowels for attaching insulation. Varieties of dowels for thermal insulation of surfaces with mineral wool and expanded polystyrene

Dowel-nails.

If earlier for the so-called blind fastening a piece of dense wood was used, which was driven into the wall to insert a self-tapping screw, today the task home handyman noticeably simplified. The homemade fastening devices have been replaced by a dowel-nail used for fastening various designs. A dowel-nail is used when it is necessary to ensure reliable fixation of an object to a concrete, stone or brick support. Taking into account the needs of the modern construction market, dowel-nails have a lot of varieties and classifications. Below we will look at the most popular solutions that feature a dowel-nail.

Let us immediately note that dowels should be distinguished by the type of base into which they can be driven. Dowels used for solid walls that do not have voids are manufactured separately. Dowels are also used for porous walls, especially in cases where fastening with standard fasteners (anchor, self-tapping screw, screw) is not possible.

Depending on the operating conditions and the structure that needs to be secured, the dowel, like the reinforcement clamps, can be endowed with unique characteristics. For example, the dowel for thermal insulation, known to any installer, has become widespread due to the unique design of the outer cap. That is, the dowel for thermal insulation is used in cases where adequate insulation of the room is necessary. In addition to the fact that the thermal insulation dowel ensures heat retention, it has excellent anti-corrosion properties. Thermal insulation dowel can be used for various surfaces: concrete, natural stone, porous and solid brick.

The material from which the dowels are made gives the fastening element unique characteristics. In addition to the popular steel dowels, builders are increasingly resorting to the use of plastic fastening materials, since their performance qualities are largely superior to competing offerings.

To be fair, it should be said that fungi for attaching insulation are not the only installation method. But in most designs they are used. Even in situations where, for example, polystyrene foam sits on adhesive foam, with a “wet facade” they additionally use fungus for insulation. Let's gradually understand the operating principles of this “miracle”, select the desired type of fastening and calculate the cost.

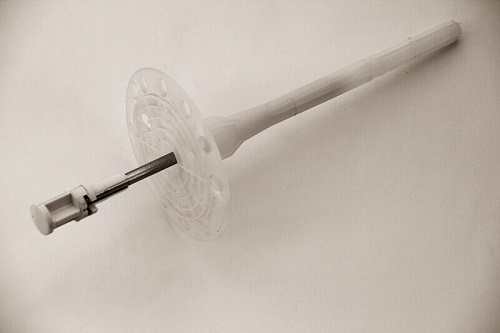

Dowels for thermal insulation are fastening elements consisting of several parts. Namely:

- The hat is its task to distribute the load over the surface of the material being fixed;

- Spacer element- it carries the load and creates a friction force that ensures that the insulation is held on the wall;

- Nail - hammered into the spacer element for tight fixation;

- Some types of insulation fungi have an anchor sleeve for additional fastening.

- Also, there are expansion washers- their task is to increase the contact area with thermal insulation and distribute the load over the surface. In practice, such washers are used for soft materials in order to avoid their deformation.

So, a disc dowel for fastening is a mechanical element with the help of which the insulation is attached to the wall.

Fastening requirements

Thermal insulation anchors are subject to high loads, perform in alkaline environments and are exposed to extreme temperatures. This means they must meet several criteria.

We have set the basic requirements for fasteners for insulation; now it is important to see how the modern market satisfies these requirements.

Kinds

To put it simply, there are two main types of umbrellas.

Made from galvanized steel

The nail of such umbrellas in most cases is made of galvanized steel (sometimes polyamide). And although this material resists corrosion more than other metal ones, it is still not completely protected from it. There is a second drawback. Metal conducts heat well, which means that cold bridges can form at the attachment point and condensation can accumulate. Over time, cracks may appear at the attachment points. This type of fasteners has a higher cost.

The nail of such umbrellas in most cases is made of galvanized steel (sometimes polyamide). And although this material resists corrosion more than other metal ones, it is still not completely protected from it. There is a second drawback. Metal conducts heat well, which means that cold bridges can form at the attachment point and condensation can accumulate. Over time, cracks may appear at the attachment points. This type of fasteners has a higher cost.

Main characteristics:

- Dowel material: impact-resistant polypropylene.

- Anchor material: low carbon, galvanized steel;

- Temperature range: -55 – +60 degrees;

- Load: up to 750 kg per square meter.

As a conclusion: such fungi are used in the case of attaching heavy insulation, when the use of plastic is impossible.

Made of plastic

Dowel for thermal insulation with plastic nail. They are used more often than metal ones, but they are less expensive and less durable. Although even their performance is quite impressive. The temperature ranges from -40 to + 80 degrees. Such umbrellas are also able to withstand loads from 20 to 380 kg per square meter. Nylon nails are also classified as plastic.

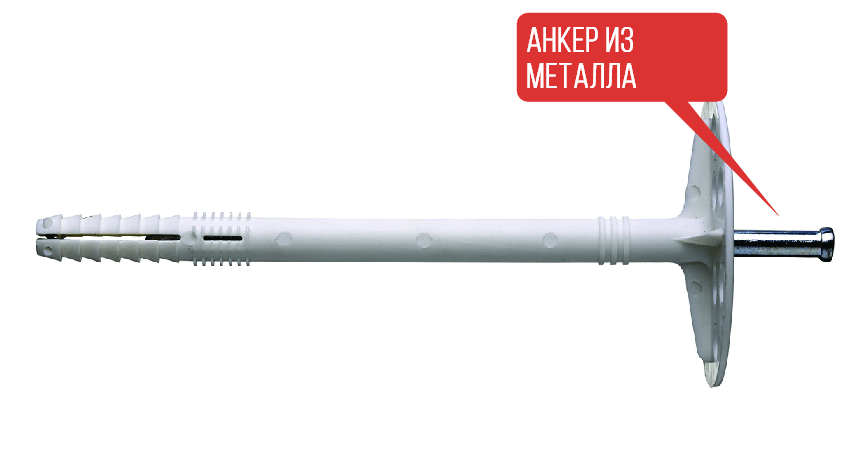

With thermal head

Thermal insulation dowels with thermal head are umbrellas with metal nails. A polymer head is placed on the end of the anchor. This approach is used for different types walls, but is especially necessary for wooden ones. The purpose of the head is to reduce thermal conductivity. Such elements have a higher cost (the highest among dowels), but also the lowest thermal conductivity and strength.

In addition, fungi are distinguished by length. This is an important indicator that needs to be calculated correctly. The diameter of the rod for the anchor is also distinguished. Most often, rods with a diameter of 8-10 mm are used.

If the fastening element is chosen incorrectly, it will not hold the thermal insulation. And you will have to tear it off along with the attached sheets. How not to make a mistake and calculate the required length right away?

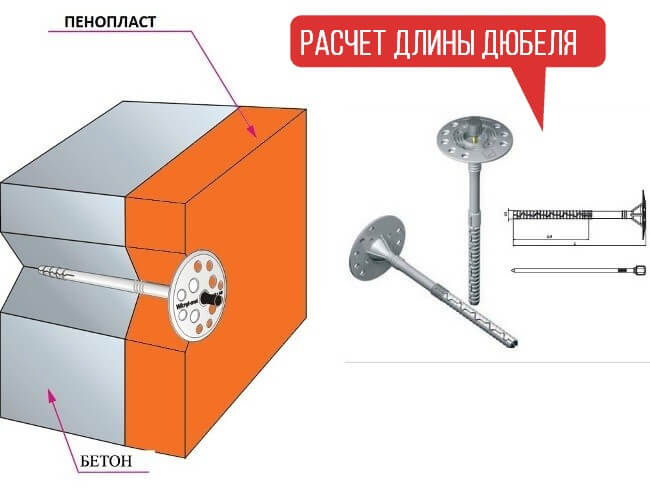

The dowel problem. This is where you need to get to. On the way to a solid surface lie:

- The insulation itself;

- Thickness of the adhesive (if any).

In addition, it is worth considering that the dowel must go into the wall to a depth of 50 mm.

Thus, we calculate the required length using the formula:

L = H + I + K + W.

L – required final dowel length;

H – thickness of the heat-insulating layer;

K is the thickness of the old plaster or adhesive to which the insulation is attached;

I – fastening the dowel into the concrete/brick/wooden base of the wall (at least) 50 mm.

W – margin for wall curvature.

For example, if you use foam plastic with a thickness of 50 mm and use a thin layer of glue - 5-10 mm, a dowel 110 mm long will be enough for you. If the wall is flat. But, if the wall distortion reaches 50 mm, it is worth adding this figure and then you will need a dowel of 160 mm or more. If we increase the thermal insulation layer to 100 mm, in the latter case we will need 210 mm of rod length.

When choosing fasteners: longer does not always mean better. If insulation occurs, for example, in an apartment, the thickness of the walls may be especially small and you need to correctly calculate the length.

Fastening schemes

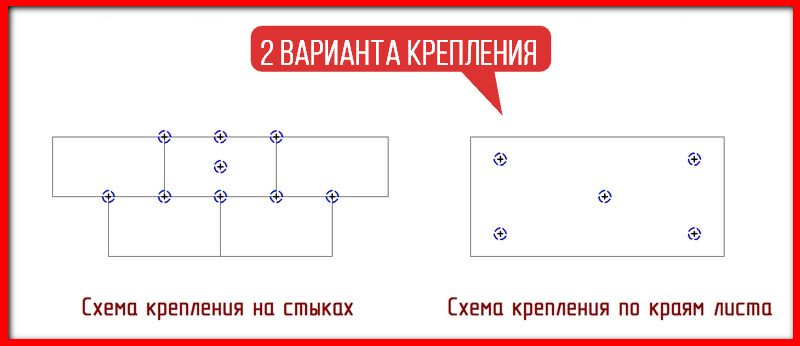

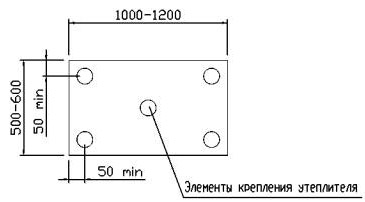

In the first approach, 5-6 dowels are needed per 1 square of material (as a rule, it is approximately equal to 1 square meter). 4 are attached in the corners (5-10 cm from the edge) 1-2 in the center.

According to the second scheme, dowels are driven at the junction of two slabs. Thus, one cap holds three slabs at the joint. With this approach, one dowel needs to be driven in the center.

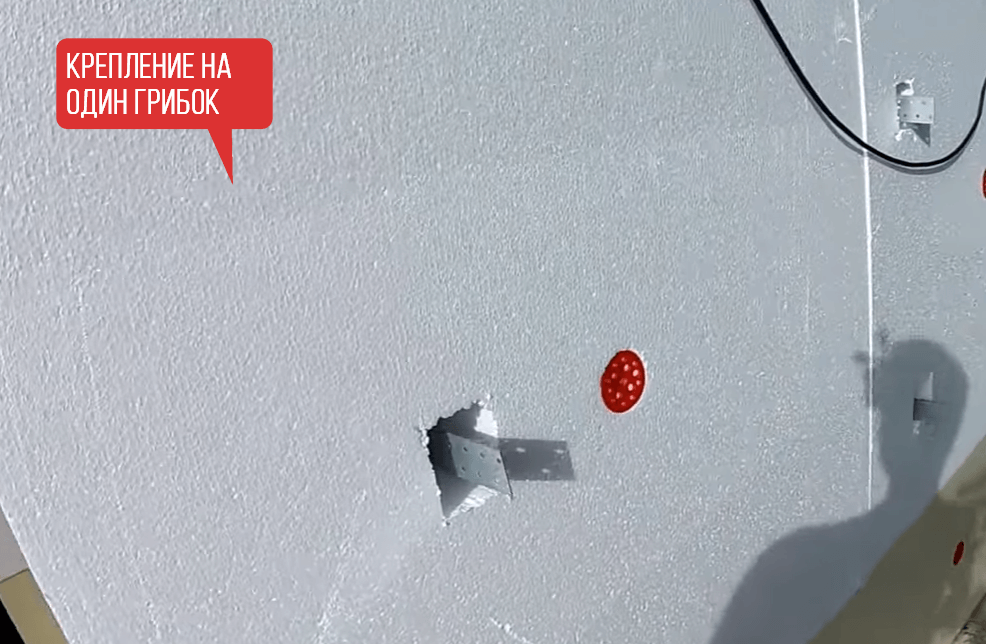

For the sake of the notorious economy, craftsmen manage to get by with just one dowel per slab in the center.

When determining the number of fasteners, you must also take into account the number of storeys of the building and the place where the insulation is attached. More fastenings are recommended at corners. On buildings higher than 8 meters there are 7 fastenings per square. On buildings above 20 meters there are 9. This is due to the increased wind load and the load on the lower rows of thermal insulation from the upper ones.

Installation

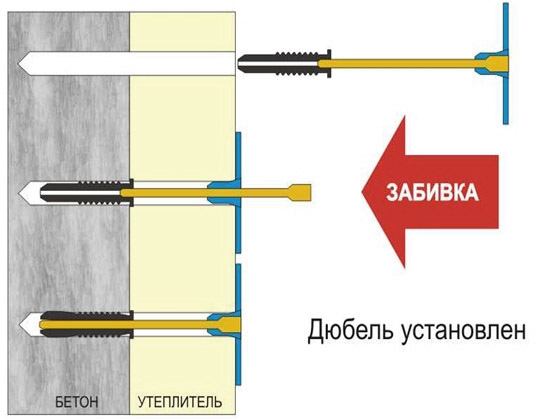

Using a dowel to attach insulation occurs in 3 stages:

- A hole is drilled corresponding to the diameter of the rod and exceeding its length by 10 mm;

- The dowel is inserted manually (its head should be flush with the insulation);

- The fixing anchor is inserted and hammered.

If you are using an extension cuff, it must be put on before inserting the fungus!

If available, cover the cap with a lid.

To fasten thermal insulation made of expanded polystyrene, mineral or glass wool, special devices in the form of fungi (known as “umbrellas”, facade or disc dowels/nails) are used. The basis for reliable adhesion is the usual friction force; this fastener is used only once. As a result, the requirements for site preparation and installation are increasing. An important factor is the consumption of material and its dimensions (preliminary calculation is recommended); if a smaller number or unreasonably short parts are used, the thermal insulation will not hold up.

Distinctive features of the fungus are a wide cap and an expandable long leg, fixing the slabs in a vertical position when insulating walls or in a suspended state during roofing work. This is the only type of construction fasteners that goes completely deep into the facade. The dimensions of the core and sleeve of the fungus depend on the thickness and properties of the insulation (from 80 to 300 mm), the diameter of the cap is standard - 59. Spacer notches with sharp edges on the body contribute to the reliability of fastening; they face the plate and do not allow the dowel to come out of the wall. The quality of fixation is affected by the thoughtfulness of the holes on the cap (or roughness), which are literally pressed into the insulation.

Dowels with a disc head are suitable for many materials, regardless of their density and structure. Modern fungi for fastening insulation are not subject to corrosion and thermal influences, they are absolutely non-flammable. The raw materials are: for the head - low-density polyethylene (polypropylene), for the wedge - galvanized steel or polyamide. Wide nylon plates - rondoli - are sometimes used to attach soft insulation, but impact-resistant plastic is still preferable. The exception is installation and operation at abnormally low temperatures. environment, in this case, polypropylene becomes brittle and collapses.

Varieties

Depending on the type of cap and material, fungi are distinguished with:

- plastic anchor;

- metal rod;

- thermal head.

The first ones are made entirely of polypropylene, distinctive feature Conical holes on the cap serve to improve the quality of adhesion. Such products have minimal thermal conductivity (≤0.004 W/m∙K), do not create “cold bridges”, can withstand temperatures from -40 to 80 °C and a load-bearing load of 20–380 kg/m2. Plastic anchor mushrooms are suitable for attaching lightweight insulation to concrete, brick and stone walls. The price is low, they are not subject to corrosion, but are of little use for installing heavy insulation.

Metal anchor mushrooms have a steel nail (galvanized or heat treated low carbon). The spacer elements and the cap of this type are made of impact-resistant polypropylene, the sizes are slightly larger than the others. They cope with differences from -55 to 60 °C and load-bearing loads of up to 750 kg/m2. The disadvantages include the appearance of “cold bridges”, the advantages include adhesion with heavy thermal insulation.

It is worth buying dowels with a thermal head for attaching insulation boards to wooden wall. The end of the steel wedge is fitted with a small plastic part to reduce heat loss. Such fasteners can withstand loads of up to 920 kg/m2. Their cost is high (up to 30 rubles per piece), but this is compensated by minimal heat loss and chemical resistance.

![]()

Installation technology

To properly fasten the insulation with fungi, the following operations are performed sequentially:

- Calculation of length and consumption.

- Marking for future fasteners. Maximum permissible step: horizontally - 80 cm, vertically - 30.

- Preparing the seat: drilling holes in the insulation and the wall with a diameter of 10 mm to a depth that is 5–10 mm greater than the length of the fungus stem.

- Pressing in the dowel until the cap and insulation are completely joined. In this case, a hammer is not used; the work is carried out manually.

- Inserting a nail and driving it until it finally hits the wall.

- Closing the cap with a protective lid with fixation in the center.

When insulating walls, the old plaster is always removed; if this is not possible, the drilling depth is increased. In case of forced shortening of the fungus stem, the cut end must be sharpened. For brick and dense concrete, a length of 50 mm is enough; for loose or hollow building materials, it is better to buy fasteners of at least 100. The recommended value for the depth of the hole for the fungus is checked with the sellers.

Calculation of flow and length

When attaching insulation to 1 m2 of surface, from 4 to 10 products are required; for more accurate information, contact the supplier: each type of nail has its own size. It is not economically feasible to exceed the number of fungi; in addition, any additional hole reduces the overall thermal resistance of the house.

The length of the leg of a disc nail is determined as the sum of the thickness of the thermal insulation, adhesive composition, the size of the spacer part (minimum 40 mm, the value depends on the type and is specified in advance), and the deviation of the working surface from the vertical. Preliminary calculations should not be neglected; fungi for attaching insulation are cheapest to buy in bulk, but there is a risk of purchasing a large batch of unsuitable products.

Price

| Name of fungus, purpose | Dimensions, mm | Maximum insulation thickness, mm | Minimum hole depth, mm | Price for 1 piece, rubles |

| Dowel with a propylene cap. For adhesion to stone and concrete | 10×80 | 50 | 40 | 3 |

| 10×110 | 60 | 55 | ||

| 10×180 | 130 | 60 | 5 | |

| Dowel with a galvanized steel rod for fastening polystyrene foam and layered insulation to concrete and brick bases. The connection is made by mechanical driving | 10×90 | 60 | 40 | |

| 10×120 | 70 | 55 | 6 | |

| 10×300 | 240 | 70 | 20 | |

| Mushroom dowel made of polypropylene with a metal thermal head, for attaching thermal insulation using the “wet facade” technology | 10×80 | 50 | 40 | 7 |

| 10×140 | 100 | 55 | 10 | |

| 10×220 | 160 | 70 | 15 |

| Articles |

To make plastic dowels, polypropylene, polyamide, or nylon can be used. The main advantage of polymer dowels is their low price, but the strength characteristics of such products leave much to be desired.

Plastic dowels can be used to attach thermal insulation to strong surfaces made of concrete or brick, but they are not suitable for fixing heavy insulation on hollow walls or surfaces made of foamed concrete.

The average cost of one dowel for thermal insulation with a polymer nail is about two rubles per 1 piece.

1.2 With a metal nail

Metal dowels are an order of magnitude stronger than their polymer counterparts, but their use is limited by the high thermal conductivity of metal, which impairs the overall efficiency of insulation.

Metal dowels form cold bridges - elements whose thermal conductivity is worse than the thermal conductivity of the entire structure.

Also, dowels with a metal nail are prone to corrosion; during operation, they can form yellow rust spots on the plastered facade.

The average cost of a dowel with a metal nail is 3.5-4 rubles.

1.3 With thermal head

Thermal head dowels are a widely used alternative to metal dowels. They are based on the same steel nail, but its head is covered with a material with low thermal conductivity.

As a rule, impact-resistant polyamide is used as a coating, which has a thermal conductivity of 0.027 W/μ, which is comparable to the same characteristic of most popular insulation materials.

The metal nail is completely recessed into a polymer case, as a result of which such a dowel is not afraid of moisture and does not corrode.

The cost of products with a thermal head varies from 4 to 6 rubles per piece, depending on the manufacturer.

1.4 Features of quantity calculation

To ensure reliable fixation of the insulation, it is necessary to use high-quality mushroom dowels, and it is necessary to correctly calculate the required dowels. This can be done using the following formula:

D = T + K + I + Z, in which

- T – thickness of the insulation used;

- K – thickness of the adhesive used to fix the thermal insulation panels;

- I – the length by which the mushroom should go deeper into the wall (no less than 4.5 centimeters);

- Z is an optional value used when the wall deviates from the vertical; it is used as necessary.

As a rule, to fasten foam panels with a thickness of 5 centimeters, a mushroom dowel 10.5 centimeters long is used.

The length of the anchor of the dowels, with the help of which the insulation is attached to walls made of brick or concrete of grades M100, M200 and M300, should be 50 mm. If the insulation is fixed to walls made of hollow brick or foam concrete (gas blocks, foam blocks, cinder blocks), it is necessary to use fasteners with 100 mm anchors.

When choosing a mushroom dowel for attaching thermal insulation, consider the advantages and disadvantages of the material from which it is made.

Installation of mushroom type dowels

"Mushroom dowel with polyamide nail:

- Pros: does not form cold bridges, as it has low thermal conductivity; not afraid of moisture and corrosion;

- Disadvantages: has low strength, which does not allow the use of such dowels for attaching thermal insulation to facades multi-storey buildings. They have the same disadvantages.

In general, dowels with polyamide nails are well suited for attaching low-density slab insulation to brick or concrete walls.

Products with metal nail:

- Pros: high strength;

- Cons: afraid of corrosion, worsens thermal insulation properties insulation, as it forms cold bridges.

Using dowels with a metal nail, you can attach insulation of any density - mineral wool, polystyrene foam, polystyrene foam, to both ordinary and hollow walls made of brick or concrete.

Dowel mushroom with polypropylene nail:

- Pros: low cost, low thermal conductivity, which eliminates the formation of cold bridges; does not corrode;

- Cons: durability.

The scope of operation of this dowel is similar to mushrooms with a polyamide nail.

Products with thermal head:

- Pros: high strength, not afraid of corrosion, does not form cold bridges;

- Cons: the price is the same

Dowels with a metal nail, the head of which is covered with heat-insulating polypropylene, are universal option, with which you can attach any insulation to any surface.

2 Features of installation of thermal insulation

The technology for installing any slab insulation - polystyrene foam, polystyrene foam, or penoplex - with mushroom-type dowels is identical. All insulation work essentially boils down to the following algorithm:

- Preparation of the insulated surface;

- Installation of panel thermal insulation on an adhesive solution;

- Fixing panels with dowels;

- Treatment of insulation joints;

- Installation of insulating film;

- Thermal insulation sheathing decorative material, or plastering.

Before installing the insulation, it is necessary to prepare the surface - remove the plaster, repair cracks and irregularities, and degrease.

Next, panels of expanded polystyrene, polystyrene foam, or penoplex are mounted on a special adhesive composition that does not contain organic solvents - toluene and acetone. During installation, the adhesive mixture must be evenly distributed over the entire back surface of the insulation.

To avoid shifts in the thermal insulation under its own weight, a metal profile is installed under the first row of slabs, which takes on the function of support.

After the day required for the solution to dry, fungi are used to further fix the thermal insulation.

To drill holes, drills are used, the diameter of which is equal to the diameter of the leg, and the length of the hole should be one centimeter longer than the length of the dowel, so that dust collected in the hole does not interfere with reliable fixation.

Building codes define the following standards for the number of dowels used:

- For attaching thermal insulation to interior walls, or on facades one-story buildings For every square meter of insulation, five pieces are needed - 4 in the corners, and one in the center of the panel;

- For fastening on the corners of buildings - 6 pieces each (fungi are installed parallel to each other);

- For fastenings on the facades of buildings with a height of 8 to 20 m, 7 pieces per 1 m² of insulation are required (parallel + 1 in the center);

- For fastening on the facades of multi-storey buildings with a height of over 20 meters - 9 pieces per square meter of thermal insulation.

It is best to place fungi at the joints of foam or penoplex panels, since this method does not lead to a significant increase in holes in the thermal insulation, which negatively affects its effectiveness.

If the mushroom dowel needs to be installed in metal coating made of corrugated sheeting, a self-tapping screw is attached to the dowel leg, after which the thermal insulation is pressed through so that the self-tapping screw reaches the insulated surface.

After this, using a screwdriver, the dowel with a self-tapping screw tip is screwed into the metal. The depth of the hole for the screw should be at least 10-15 millimeters.

Upon completion of the installation of thermal insulation, the joints between the foam plastic or penoplex panels are glued with aluminum reinforcing tape. The joints between the floor or ceiling and the adjacent panels are sealed with polyurethane foam.

2.1 Installation technology (video)

The optimal solution for old or thin walls is to install insulation. It will not only keep your home warm, but will also transform its appearance. Its durability and functionality depend on the thickness of the material, its properties and the choice of fasteners. In most cases, special dowels are used for its installation. They are widely used due to their versatility.

They can attach any insulation to various surfaces - concrete, brick, stone and wood. These fasteners are a structure consisting of a wedging nail and a wide head that holds the insulation filler, and the long part is responsible for rigidly fastening it to the required material.

Insulation materials are made in the form of plates. They are made of mineral wool or glass wool, as well as polystyrene foam. If it is necessary to fasten the last material, then its installation should be done before applying the plaster and reinforcing layer.

Therefore, when choosing a material, you need to focus on them. Typically, plastic varieties are used, and for attaching plastic insulation, products made of polypropylene or analogues made from nylon are used.

A dowel designed for thermal insulation is indispensable during installation due to its unusual design, consisting of three parts - a clamping component in the form of a cap, an internal strong core and an anchor element - a sleeve.

The video shows a dowel for attaching thermal insulation:

The advantage of dowels intended for insulation:

- reliability of fastening and good fixation of thermal insulation foxes;

- façade fungi do not destroy, rot or corrode;

- their design allows them to withstand large load-bearing loads;

- the insulation remains intact for a long time due to the fact that the plastic discs of the dowels smooth out changes in the material when it expands or contracts;

- due to the expansion mechanism of the dowels, their adhesion to the wall is improved;

- such fastening does not create additional cold entry points;

- durability and strength.

You can learn about how to use construction nails GOST 4028 80 from this

What functions do they perform, features of application

To securely fasten the insulation, the fastening element must meet several requirements:

- during installation, hold the thermal insulation slabs in place and prevent them from moving;

- in windy weather, protect the structure and promote uniform load distribution;

- prevent the formation of surface stresses in the decorative layer applied to the insulation;

- ensure strong fastening of two surfaces - the decorative layer and the base.

You can learn how to use fasteners for decking boards

On the video - a disc dowel for thermal insulation:

Disc-shaped dowels are used mainly for insulating building facades, and dowel-nails are used to improve the thermal insulation of ceilings and roofs.

Fasteners with plastic nails suitable for slabs and rolls of insulation made of glass wool, polystyrene foam, plastic, mineral wool and other materials. A disc dowel can securely fix them on concrete, brick and foam concrete surfaces.

The type of dowels used depends on the base on which the fastening is made:

- for expanded polystyrene and lightweight materials, a dowel with a plastic core and reinforced glass fiber is used;

- Booster cuffs are best suited to wooden surfaces, the design of which has a hole for a nail or screw and a propylene cap;

- denser materials require the use of dowels with a galvanized metal nail;

- its analogue with a thermal head is used for light-weight insulation materials that cannot be secured with a plastic nail.

How the fastening occurs and how the panels are attached to the ceiling can be found in this

Installation

Installation of insulation must begin with marking the fastening points. For clarity, you can mark them with a marker for construction work. Then you need to:

- Drill a Ø 10 hole through the insulation and the main surface, its depth should be ten centimeters longer than the dowel rod.

- Fill the resulting voids with plate-shaped products, which must be manually pressed with force until their caps sit close to the insulation.

- Then the selected nail is driven into their core. If there is a thermal head, it is put on the protruding part of the rod.

In the video - more information about dowels for attaching thermal insulation:

Manufacturers and prices of their products

For the convenience of choosing dowels for insulation, the estimated cost of products from popular manufacturers is given.

| Company | Type of dowel | Size, mm | Quantity in one package, pcs. | Price, in rubles |

| Koelner | with metal nail | from 10×(90…220) | 250 | from 800 to 1500 |

| Technics | with plastic core | 10×(70, 80) | 100 | 320350 |

| Wkret-Met | with galvanized nail | 10×120 | -//- | 820 |

| Strezzar | with polyamide rod | 10×(140, 160,180 and 220) | 50 | from 400 |

| Pan Insulate | with plastic nail | 10×(70…160) | 100 | from 340 to 450 |

| with metal core and thermal head | 10×(90…200) | 50 | from 650 |

The use of facade dowels is very widespread, since it not only firmly holds the insulation on the main wall, but also serves as a fuse for everything appearance home from external negative influences. It also provides additional support for the heat-insulating material and does not increase the weight of the structure, especially if a dowel with a plastic rod is chosen.

Read also...

- The meaning of the name Daniel, origin, character and fate of the name Daniel Daniel what does it mean

- Zodiac sign Pisces child girl

- The meaning of the name Savely. Interpretation of the name. Savely: the meaning and history of the name, fate and character Savely's Angel Day

- Gregory meaning of the name - character and fate