Water meter brand for wastewater discharge. A brief overview of the market for Russian ultrasonic wastewater flow meters and solving problems of instrumental metering of sewage. Non-pressure flow metering

Organization of commercial accounting wastewater at the SPS of settlements and enterprises is becoming more and more relevant. When designing wastewater metering units, it is necessary to analyze the structural, technological and operational conditions of a specific sewage pumping station and knowledge of the operating features of various types of flow meters. RANET ENERGO LLC is a company that has already achieved success in this difficult business.

RANET ENERGO LLC, Korolev

LLC RANET ENERGO was founded in 1990 and is located in the town of Korolev near Moscow. Fields of activity of the enterprise: energy saving, ecology and automation. A feature of the company since its inception has been the performance of work at remote sites throughout the country. RANET ENERGO LLC was the first in the country to install metering devices on free-flow pipelines and open channels. In total, more than 420 metering stations for waste, storm, and circulating waters have been designed and implemented on free-flow pipelines and open canals. The company has designed water control stations at the outlets of industrial waste water of industrial enterprises. The station includes a waste water flow meter, automatic analyzers of oil products in water, pH and temperature values.

Figure: 1. Scheme of the water balance of the enterprise

The enterprise has successfully organized commercial water metering at many facilities. Electromagnetic (EM) and ultrasonic (US) flow meters from different manufacturers are used as metering devices. Full bore EM and US flow meters are used depending on operating conditions; Ultrasonic flow meters with insertion primary converters (PP) and ultrasonic flow meters with overhead PP. The main tasks in the design of metering stations at pumping stations (NS) are to organize straight measuring sections inside the NS building. In cases where this cannot be achieved, measuring chambers are built outside the NS.

An analysis of the water balance diagram of the enterprise (Fig. 1) shows that an integral part of the task of integrated energy accounting, along with heat energy and coolant, cold water is the organization of commercial metering of waste and storm water in gravity pipelines and at sewage pumping stations (SPS).

Some general issues arising in the creation of wastewater metering systems, and the features of wastewater metering in gravity pipelines, were considered earlier in.

This material is devoted to the design features of wastewater metering units at the sewage pumping station.

Most of the previously built and currently under construction SPS are not equipped with waste water metering units. Meanwhile, the organization of commercial accounting of wastewater at the sewage pumping station of settlements, enterprises, cottage settlements is becoming more and more urgent.

When organizing commercial metering of wastewater at the design stage of metering units, it is necessary to solve two main issues:

Choose the place of installation of metering devices (flow meters);

Select the type of metering devices.

There are no standard solutions for wastewater metering units at the sewage pumping station, since the sewage pumping station is very significantly different from each other in architecture, the layout of technological equipment, the location and diameters of pipelines and valves; type, number and performance of pumping units, etc.

Therefore, when conducting a pre-design survey of the pump station, the totality of all initial data on the technical characteristics and location of technological equipment, and operational features are analyzed. To select the type of flow meters and the places of their installation, it is necessary to know the types and capacity of the pumps, the pump operation time after switching on (the duration of pumping out the receiving tank).

Metering units should be mounted on the outlet pipelines (outlets) of the pump station.

However, at many sewage pumping stations, it is impossible to place measuring sections of pipelines with flow meters inside the sewage pumping station building. In these cases, outside the SPS building, special measuring chambers are built.

The larger the diameters of the pipelines, the more difficult it is to place the measuring sections in the SPS building without significant rewiring of pipelines, shut-off valves.

There are other problems at the SPS of low productivity.

Now such pumping stations are under construction, on which all equipment is located underground. Submersible pumps are used, the machine room and the heated pavilion are absent. At such SPS, measuring sections can be partially below the water level in the receiving tank, and flow meters can be installed directly above or under water.

Usually the SPS has one or two outputs (working and reserve), on which metering devices are installed.

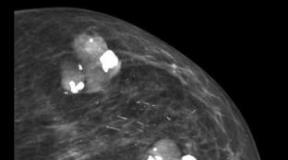

Figure: Primary converters of ultrasonic correlation flow meters installed on existing pipelines without dismantling

But it doesn't always work that way. For example, at the sewage pumping station of the industrial storm sewer of one of the enterprises near Moscow there is one outlet - a collector with a diameter of DN 600 mm. Five pumping units of various capacities are installed in the machine room, which are connected to the collector by pipelines with a diameter of DN from 150 to 250 mm.

The customer was offered two options for the implementation of commercial wastewater metering:

The measuring section is mounted in the machine room parallel to the existing collector DN 600 mm;

A measuring chamber is being built outside the SPS building.

Both options were rejected by the customer due to the complexity of implementation (cramped conditions and large volume installation works in the turbine room, wetland).

Then the third option, which was optimal for this case, was implemented in the project. Electromagnetic flowmeters, since the length of the measuring sections are limited, are installed in vertical sections after each of the five pumps. Wastewater accounting is carried out by summing up the readings of all flow meters.

The necessary conditions for the correct operation of most types of flow meters are: water supply at the measuring sections with a full cross-section, the absence of a gas phase (air) in the measured liquid, and the absence of counterflow at the measuring sections.

Figure: Installation of clip-on sensors for an ultrasonic flow meter

For the pump station, all these conditions are of particular importance, since the pumps operate in the start-stop mode and the problems of the formation of air bubbles, water-air mixture, and reverse water flow occur quite often.

Now about the types of flow meters used for wastewater metering at the sewage pumping station.

SPS can use electromagnetic and ultrasonic flow meters with attachment or cut-in sensors, as well as ultrasonic correlation. In our opinion, tachometric and vortex flowmeters should not be used for wastewater accounting.

Of the advantages of electromagnetic flowmeters in relation to the conditions of the SPS, there is perhaps only one thing left - short measuring sections.

The wide range of measurements of electromagnetic devices in this case, as a rule, does not matter.

But there are exceptions. Sometimes it is necessary to provide flow measurements over a very wide range. This happens in cases when frequency converters (FC) are used, capable of changing the water flow rate at the outlet of the pump station in a wide range.

For example, we installed ultrasonic correlation flow meters on two DN 500 pipelines of one of the pumping stations near Moscow. After several months of successful operation of metering units, we received a signal that the flow meters were malfunctioning during operation - periodically zero flow readings appeared on their displays when the pumps were running. The study of the situation made it possible to find the reason for the "failure" of metering devices. It turns out that after the commissioning of metering units at the pump station, emergency situations were installed, which, in some operating modes of the pump station, created a flow rate in the pipes below the minimum measured flow rate of 45 m3 / h.

Therefore, further adjustment of wastewater accounting at the sewage pumping station was carried out by appropriate tuning of the system of frequency converters.

In addition, if there are frequency converters at the SPS, it is necessary to pay attention to the fact that emergency situations can create powerful interference that can disrupt the operation of metering devices.

It is also impractical to use full-bore electromagnetic flowmeters on pipelines of DN over 200–300 mm due to the high cost of such devices.

Therefore, our company often uses ultrasonic flow meters in projects of wastewater metering units at the sewage pumping station.

Ultrasonic flow meters can be installed on pipes of almost any diameter.

Where possible and appropriate, ultrasonic transducers are inserted into existing pipelines without dismantling them. In this case, existing pipes are used as measuring sections, which, of course, is an important advantage of the ultrasonic measurement method.

Another significant plus of ultrasonic devices is the possibility of their verification by an imitation method without dismantling the primary transducers and without spilling.

It can be argued that the realization of the last two advantages of ultrasonic flow meters inevitably leads to a decrease in the accuracy characteristics of metering units. And indeed it is. However, such strict requirements are not imposed on water metering units (for example, there are no restrictions on the error of metering devices), as on heat energy and heat carrier metering units.

Therefore, both the insertion of ultrasonic transducers into existing pipes and the use of flow meters with clamp-on sensors for wastewater metering, in our opinion, are justified and expedient.

Customers are particularly attracted to flowmeters with clamp-on sensors due to the minimal installation costs, which, of course, is an absolute advantage over flowmeters with insert sensors. It is convenient to install flowmeters with clamp-on sensors on plastic pipelines.

However, flowmeters with clamp-on sensors have their own disadvantages.

First, even when using flowmeters with clamp-on sensors, it is not always possible to do without re-installing the pipelines, because in any case, it is required to organize measuring sections of certain lengths and diameters.

Secondly, during the operation of these types of flow meters, adjustment and maintenance are often required.

And most importantly, the reliability of the readings of such flow meters depends on the professionalism of the adjuster, and the representatives of the operating or controlling organizations often do not have sufficient technical training to check how correctly the flow meter was set up.

It should be noted that the cost of work on the organization of wastewater metering depends on the adopted design decisions. Moreover, the cost of implementing different solutions can differ significantly.

Thus, when designing wastewater metering units at a sewage pumping station, it is necessary to analyze the structural, technological and operational conditions of a specific sewage pumping station, as well as knowledge of the operating features of flow meters of various types and manufacturers.

Literature

Popov A.G. Custody transfer of waste water - problems and features. "EnergoSovet" energy saving portal

A.G. Popov, Ph.D., Director

RANET ENERGO LLC, Korolev,

The Russian Law on Energy Saving requires enterprises and housing and communal services to organize wastewater accounting. Many faced such a question for the first time. First, you need to define the term itself and find out the ways of their formation and the place where they go.

Wastewater is water contaminated with industrial waste and household waste, as well as those that are formed as a result of atmospheric precipitation within industrial facilities and settlements. Runoffs from the territory are removed using the sewerage system. This is a whole complex of engineering equipment, structures and sanitary measures that ensure the collection and disposal of effluents, as well as their disinfection and treatment before being discharged into water bodies or utilized.

There are two types of sewerage:

- internal;

- outdoor.

The internal system is located inside the structure and buildings. It serves to collect and discharge contaminated water into the external sewerage network, in which wastewater is transported outside the territory of industrial facilities and settlements. Internal sewerage includes elements such as bends, sanitary fittings, risers and outlets from buildings.

The elements of external sewerage include pressure and gravity pipes, treatment facilities and sewage pumping stations, in other words, SPS.

The sewerage system implies separate or joint disposal of wastewater of such categories: industrial, domestic and rainwater. The sewerage system itself is separate and combined. With a separate system, conditionally clean industrial and rainwater are removed through one network, and industrial and household water - through another. The public system uses a common network of canals and pipes to discharge all the above categories of wastewater.

State bodies are engaged in accounting. Installation, replacement and inspection are also controlled by the state. Subscribers are required to provide representatives with access to plumbing and sewerage equipment. Vodokanal cannot do this for free. Therefore, sewerage services are paid in the same way as water supply services, that is, in proportion to the volume of discharged water.

From the above, we can conclude that for all its cheapness (there are no costs for organizing accounting of polluted waters), the accounting of effluents is carried out approximately. It is not able to take into account the characteristics of the consumer, which quite seriously affect the “sinks / consumption” ratio, both in one direction and in the other. It should also be remembered that both consumed cold and consumed hot water enter the sewer system. The supplier of such water is most often different companies, while the waste water falls entirely on Vodokanal.

Imported, rainwater, buried in the ground during pipeline accidents, drained past the sewerage system and evaporated water are “disturbing” factors. It is because of them that the “consumption / effluent” method works normally only for small consumers, for example, in the residential sector, which “traditionally” uses water. In other cases, it is necessary to organize accounting using instruments.

Accounting for polluted water in some cases will be beneficial to the side that drains, and in some cases - to the side dealing with wastewater. But all the same, accounting will be "transparent" and objective in any case.

Method of metering pressure effluents

It has already been mentioned that waste water is transported through pressure and non-pressure pipelines. The accounting system of both systems is somewhat different. It is quite simple to measure the volumes of pressure effluents. Measurement of volumes of tap (ordinary) water differs from measurement of waste water only in that in the second case, the flow rate is much lower, and the degree of pollution is much greater.

As a rule, metering devices are installed at the outlet of sewage pumping stations. Most often, they are ultrasonic or electromagnetic flow meters. They are selected according to the range of measured flows. Ultrasonic devices can be used with clip-on sensors. To ensure stable operation (and reduce the load on the pumps), automatic air vents and check valves should be used.

Non-pressure flow metering

A completely different, more difficult task is the accounting of non-pressure effluents. In such a case, there is an unfilled pipe or open channel through which water flows at a low speed due to gravity.

A variable level method has been invented especially for this option. In this case, the level gauge is used as a flow meter. It recalculates the accounting of information about the measuring section with "level to flow". The Parshall and Venturi trays, which are built into the channel, act as a section. Weirs with standardized dimensions are also used. For them, the "level-consumption" formulas are obtained semi-empirically. This method works in U-shaped and gravity pipelines, and in these cases, weirs and trays are not needed. The described method is regulated by Gosstandart documents.

However, there are complaints about this method. They appear due to the fact that the starting point in this method is the results of a previously calculated pressure-flow characteristic of a pipeline, flume or weir. The more accurate the preliminary calculation is, the more accurate the device will work in the future. To determine the performance of a free-flow pipeline or a U-channel, the fluid flow rate (provided that the filling level is known) should be determined experimentally. The measurement is carried out "by eye".

For example, you can use a sliver to be thrown into a canal and a wristwatch. The error of such an experiment is awful. Therefore, there is another way - the Shezy formula. Here, the coefficient of wall roughness and the construction slope of the pipeline are taken into account. But these values \u200b\u200bcan be called theoretical, because the real bias does not always correspond to that indicated in project documentation, and the roughness of the walls and its coefficient are constantly changing during the use of the pipeline. Despite this, preliminary calculations are entered into the device. If there is an error in the original data, this can lead to inaccurate accounting. In many cases, this error may not be noticed. That is why it is necessary to involve professionals for the design and installation of non-pressure wastewater metering systems.

Domestic flow meters

The Russian enterprises "Signur" and "Vzlyot" produce devices that implement the variable level method. These are EKHO-R-02 and Vzlet-RSL flow meters. The level is measured by a non-contact method thanks to an ultrasonic sensor, which is placed above a pipeline or channel.

Each device has its own advantages and disadvantages. Benefits:

Disadvantages:

- in case of flooding, flooding of the pipeline or a change in the direction of flow at the point of measurement, the calculations become unreliable, because the main measured parameter is the flow level. If it remains unchanged, then the device will show the flow rate, which corresponds to the point of the "level-flow" graph;

- 2 years is the period of the check interval;

- formation of ice build-ups is possible on the sound guide and AP;

- long straight sections are required.

The price of such a device is approximately 45,000 rubles.

The Vzlyot-RSL flow meter has the following advantages:

Despite all the advantages, Vzlet-RSL, like any other flow meter, also has disadvantages:

- the radiation cone of the sensor has a discrepancy. Because of this, reflections from various obstacles (stationary and non-stationary) can cause measurement errors;

- use of temperature correction. In the environment, the speed of ultrasound is highly dependent on temperature, composition, humidity and air pressure. This can also correct the results.

The cost of such a flow meter is about 60,000 rubles.

Foreign devices

In addition to domestic manufacturers, foreign companies also produce flow meters. From foreign devices for measuring flow rates in free-flow pipelines and open channels, there are devices that implement the "area-velocity" method. For example, the products of Teledyne ISCO. In such devices, a sensor is placed at the bottom of the channel and, using a pressure sensor, measures the water level above itself and the flow rate (using the Doppler method). The channel parameters should be entered into the device memory in advance. It compares this data with real-time fill level information, and then calculates flow rates and volumes. The main disadvantage of this method is its price, which is much higher than that of Russian flow meters.

It should be noted that for both domestic and foreign devices, the main "enemy" will be flooding and sediment formation in the measured location. In this case, the error increases. Therefore, the flowmeter, as well as the place of its installation, requires regular maintenance.

From all of the above, conclusions can be drawn. Today, wastewater accounting is a fairly urgent task. It can be solved using various methods. And if pressure systems are not problematic, then free-flow systems can be calculated in several ways. Consumers with a small volume of waste water and an even ratio of consumed and polluted water can use the calculation method. The ratio is determined empirically. But large consumers with a changing or unobvious ratio "consumption / waste" should acquire metering. Instruments that implement the variable level method will be less expensive. But area / speed devices will cost much more. In both cases, metering units must be installed by professionals. They also require constant maintenance.

DESIGN - COMPLETE SET and DELIVERY OF EQUIPMENT - INSTALLATION - COMMISSIONING - SERVICE

Few people want to deal with water disposal (sewerage, waste water), - “ monopolists they have it all"And pay 100% of water consumption (that is, how much they received and gave away), but if fingers to estimate ", it turns out like this:

- The tariff of MUP "Vodokanal Management" consists of cold water and water disposal (sewerage, waste water):

For Taganrog from 01.07 to 31.12.2016 it looks like this - 1m3 - 58.13 rubles, which includes 37.31 rubles (cold water) + 20.82 rubles. (drainage). It turns out if you consumed 1000 m3 / month according to the meter. and the bulk of your water went, say, for watering tomatoes, drinking pets, washing a car, or something else. Then you will pay Vodokanal 58130 rubles, although you will actually consume the service for 37310 rubles. Without a solid profit is 20.820 thousand rubles. from each thousand m3, and 250 .00 thousand rubles a year. These costs can be eliminated using the Wastewater metering unit (device).

We had to participate in the court: A farm of birds and animals, has a certain water consumption, the farmer wondered how much water was spent on drinking for pets, it turned out that almost all. The court does not like various calculations, who, if not a judge, knows that they can be different, but he likes the UUSV (wastewater metering unit), there are numbers recorded and goodbye disputes.

So, start organizing resource accounting, unless, of course, swearing and arguing is not your choice. The plus is that you understand exactly the consumption and already further you can unmistakably reflect on savings or efficiency in one direction or another.

MORE DETAILS ABOUT Housing and Utilities News Zen

Instrument operation video:

A bit of legislation

The Russian Law on Energy Saving requires enterprises and housing and communal services to organize wastewater accounting. Many faced such a question for the first time. First, you need to define the term itself and find out the ways of their formation and the place where they go.

Wastewater - these are water polluted by industrial waste and domestic waste, as well as those that are formed as a result of atmospheric precipitation within industrial facilities and settlements. Runoffs from the territory are removed using the sewerage system. This is a whole complex of engineering equipment, structures and sanitary measures that ensure the collection and disposal of effluents, as well as their disinfection and treatment before being discharged into water bodies or utilized.

There are two types of sewerage:

- internal;

- outdoor.

Internal system located inside structures and buildings. It serves to collect and discharge contaminated water into an external sewerage network, in which wastewater is transported outside the territory of industrial facilities and settlements. Internal sewerage includes elements such as bends, sanitary fittings, risers and outlets from buildings.

To the elements outdoor sewerage include pressure and gravity pipes, sewage treatment plants and sewage pumping stations, in other words, SPS.

The sewerage system implies separate or joint disposal of wastewater of such categories: industrial, domestic and rainwater. The sewerage system itself is separate and combined. With a separate system, conditionally clean industrial and rainwater are removed through one network, and industrial and household water - through another. The public system uses a common network of canals and pipes to discharge all the above categories of wastewater.

Experiencecreationand operation of metering units for non-pressurized wastewater on the basis of measuring complexes "AEFT-EKOSTOK".

At present, all domestic measuring complexes and devices, on the basis of which metering units for free-flow wastewater are organized, according to the principle of operation, conditionally divided into two groups:

Below are 2 photographs of the IC "AEFT-EKOSTOK", which is on the balance sheet of one of the organizations. Despite the difficult operating conditions and the complete absence of maintenance measures, the device is used for commercial calculations and operates without interruptions for a long time. There are no claims to his testimony from the sewerage company.

Photo # 1. Measuring part with a flow meter located in a sewer well

Photo # 2. Secondary device from which the consumer takes readings. It should be noted that it is often not possible to create ideal conditions for operation - hence the disputes, lawsuits (also operating costs) and, as a consequence, the withdrawal of the metering unit from commercial operation (which means money wasted on the metering unit). Among our customers there are enterprises that have switched to the IC “AEFT-EKOSTOK” precisely because it is impossible to create conditions at their facilities for the operation of metering devices with an “indirect” measurement method.

It should be noted that it is often not possible to create ideal conditions for operation - hence the disputes, lawsuits (also operating costs) and, as a consequence, the withdrawal of the metering unit from commercial operation (which means money wasted on the metering unit). Among our customers there are enterprises that have switched to the IC “AEFT-EKOSTOK” precisely because it is impossible to create conditions at their facilities for the operation of metering devices with an “indirect” measurement method.

Usually, customers ask the following questions when considering the possibility of using the IC "AEFT-EKOSTOK":

- Question... Can the electromagnetic flowmeter handle the load during peak shedding hours? In this case, would the use of the AEFT-EKOSTOK IC lead to flooding of the sewer collector?Answer.With the correct selection of the diameter of the flow meter (design solution), the maximum throughput is set several times higher than the declared peak loads. At the moments of peak release, the pressure in the measuring section increases. Accordingly, the velocity in the measuring section also increases. The more effluent flows, the faster they pass through the measuring section. At a fairly large number of facilities where the IC "AEFT-EKOSTOK" are installed, during the three years of operation, there was not a single case of emergency flooding.

- Question... Will the measuring section gradually become clogged during operation, overgrow (lose throughput) and cause flooding of the sewer collector? Will the electromagnetic flowmeter lose its metrological characteristics due to silting?Answer.Waste water contains solid fractions. With periodic peak discharges, water with various inclusions flows at high speed through the measuring section, possible deposits are removed (self-cleaning during operation). Selective removal of electromagnetic flowmeters from objects for their technical inspection allows us to conclude that the flow path of the flowmeter has no traces of siltation.

- Question... Are various regulatory documents on the operation of sewerage networks not violated when using IK AEFT-EKOSTOK? For this reason, will the sewerage companies refuse to agree on these technical solutions?Answer.Operating standards are not violated. Non-pressure drains turn into pressure ones only in a short measuring section. Specialists of sewerage companies are also interested in guaranteed measurement results. They not only coordinate projects at the AEFT-EKOSTOK IC without any problems, but in a number of cases, issue technical specifications to the metering unit, where they prescribe the use of measuring complexes with this particular principle of operation.

- Question... Will the organization of metering units at the AEFT-EKOSTOK IC cost the customer much more expensive than the metering devices with an indirect measurement method?Answer.The most expensive component of the measuring complex is an electromagnetic flowmeter with a degree of protection IP 68. To reduce the cost, we propose to use a PRET flowmeter with a degree of protection IP 68 (manufactured by OOO Teplotron). Its use as part of the AEFT-EKOSTOK investment company can significantly reduce the cost of equipment. Metrological and operational characteristics of the PRET flow meter, the presence of unified output signals, make it possible to use it for metering stations in flooded areas and in pressure pipelines.

Photo # 3. Electromagnetic flowmeter PRET Allows to bring the cost of IC "AEFT-EKOSTOK" closer to the cost of metering devices with an "indirect" measurement method.

In addition, when determining the cost of a metering unit, one should take into account not only the cost of the equipment, but also the costs of its installation, the cost of commissioning, additional work on the sewer collector and, finally, the cost of maintaining the metering unit. In all respects, IC "AEFT-EKOSTOK" compares favorably with metering devices with an "indirect" measurement method. Installation and commissioning costs are minimal, and sewer work and maintenance are virtually nonexistent. Thus, the cost of the metering station for non-pressurized wastewater at the AEFT-EKOSTOK IC is quite competitive.

For those who live in the private sector, in order to reduce utility bills, it is recommended to purchase a meter for installation on the sewer, if a centralized collector is connected to the house. Such a wastewater flow meter will show you and the water utility staff how much less waste you send to the sewer, as opposed to the consumed water.

Important: until now, the volume of water disposal was considered to be the volume equal to the water consumption. That is, as much was taken from the water supply system, as much was poured into the sewer.

However, in the private sector not always all the collected and consumed water goes to the collector. So, washing a car or washing a carpet in the yard does not allow you to drain the liquid into the sewer. Here you can add watering the garden and vegetable garden, irrigation concrete slabs yard in the heat, a set of water in an aquarium, etc. Most often, such liquid simply goes into the ground or is used for watering garden crops. Thus, the extra 300-500 liters per week (especially in summer) are already a plus in your receipt for water disposal, which forces the owner of the house to overpay for the service.

And to prevent this from happening, you should seriously think about installing such a meter on the sewer.

A flow meter for sewage is called a special metering device that is installed on the sewer pipeline. The meter for installation on a sewer is a complex mechanism with electronic elements, designed to work in an aggressive environment. The accuracy and reliability of measurements with such devices is guaranteed by the manufacturer.

The installation of the device for metering wastewater is carried out directly in the collector in its open or closed area.

According to the principle of operation, sewage flow meters are divided into two types:

- Devices for metering wastewater by measuring the level of water flow in the pipeline;

- Instruments for metering both level and flow rate.

In the first case, the meter is used for a gravity collector. That is, in cases where sewage flows through a sloped pipe by gravity under the influence of gravity. Devices of the second type are used in pressure systems, where the sewage water current is provided by a special pump.

Types of flow meters for waste water

The modern plumbing equipment market offers users a number of sewerage meters.

Ultrasonic apparatus

Such meters have a special sensor that measures the depth of the flow and transmits data via wired or wireless communication, as well as using a special modem. The installation of such a metering device does not require complex technical work. The ultrasonic control unit for sewage has protection against various interference and overheating. Most often, such devices are installed in a non-pressure (gravity) collector.

Advantages of the ultrasonic flow meter:

- The ability to measure data in a pipeline of different diameters (including the largest one up to 350 mm);

- The ability to operate an ultrasonic meter both from the network and from batteries;

- Large mechanism memory;

- The minimum percentage of error when giving readings;

- Long service life.

However, the ultrasound machine also has disadvantages:

- Difficulty in maintenance. Especially if the ultrasonic meter is installed by the cut-in method.

- The need to clean the sensor during the operation of the meter.

Electromagnetic devices

The principle of operation of such devices resembles the operation of a vane water meter. Here, the drains pass directly through the mechanism, forcing the magnetic field to work and display data on the display.

Benefits:

- Installation and maintenance of metering devices are quite simple;

- The resistance of the mechanism to strong vibrations allows it to be installed in a pipeline near complex industrial or railway facilities;

- High accuracy of readings;

- Long service life.

Among the disadvantages are the following:

- The presence of an inaccuracy in the readings, if there is an electromagnetic interference nearby;

- Significant differences in the price of the device depending on the diameter of the flow meter;

- Possible error in operation from 0.25% to 2%.

Electromagnetic meters are used both in pressure and non-pressure pipelines.

Important: the water passing through the electromagnetic meter must be electrically conductive.

Lever-pendulum flow meter

In this case, the depth of the wastewater in the sewer pipeline is measured using a float sensor, and a special swivel blade helps to determine the flow rate.

Portable waste counter

The smallest of the metering devices. It is used if the stationary flow meter was removed for repair or diagnostics. The portable PU is battery operated and can be recharged.

Types of collectors and flow metering in them

It is known that the sewer pipeline can operate both in a non-pressure way (under the influence of gravity, that is, by gravity), and in a pressure way (using a special pump). In the first case, it will be more difficult to obtain data on the amount of discharged effluents, since both the volume and flow rate may be different depending on the situation.

In a non-pressure manifold, you can use any type of flow meters that measure either only the depth of the flow, or both the depth and the flow rate.

For the discharge pipe of the sewage system, you can use a meter that works by analogy with a simple water meter for clean water. Such devices are suitable for use in an aggressive environment with the presence of fecal debris in it.

Important: a device that takes into account both the speed and depth of the waste stream gives more reliable data.

Features of installing the meter on drains

If it is decided to install a meter for installation on the sewer in order to save money, then before buying it, you should familiarize yourself with the nuances of installing the device:

- Thus, the flow meter must be fully matched to your collector type. To choose the right type and type of meter, you can consult a specialist in the store. Remember, a mistake in the choice entails not only the loss of funds from family budget, but also constant inaccuracy in data acquisition.

- In order for the meter to give the most accurate readings, its section must be completely filled with working drains.

- The device must be installed either at the highest point of the pipeline, or at its lowest point. If the sewer collector is free-flowing, then the device is installed only at the lowest point of the pipeline.

- Installation of the meter on the sewer is allowed only on straight sections of the collector, which have a deviation angle in the horizontal plane of no more than 25 degrees.

- It is worth remembering that a good seller has a private sewage flow meter equipped with all the necessary elements for installation.

Important: it is better to entrust the installation of equipment in the sewage pipeline to narrow specialists who will perform all the work accurately and with a guarantee.

Possible inaccuracies in the calculation of drainage

It happens that the flow meter for the collector gives, in the opinion of the owner, inaccurate data. In this case, it is worth knowing that inaccuracies in the operation of the metering device may arise for two reasons:

- Supports in the pipeline;

- Manifold blockage.

In this case, you need to analyze and investigate your collector. The reasons for the appearance of backwaters in the pipeline can be:

- Breakage of the pipeline walls and the occurrence of obstacles along the flow of dirty water;

- The presence of large household waste in the water (rags, sponges, personal hygiene items, etc.);

- Possible slope of the pipeline to the side opposite to the side of the flow of drains;

- Insertion of the collector of a private house in the place where the level of drains in the central pipeline is higher.

Important: in case of household blockages, you can simply clean the collector. In other cases, complex technical work will be required.

Reasons for siltation in the sewage pipeline:

- Too little slope of the collector from the house to the central sewer line;

- Possible ingress of sand into waste water or sewer pipes;

- Insufficient sealing of the pipeline seams, which leads to the ingress of soil and possibly water into the collector.

If silted areas are found in the sewer pipeline, it is necessary to identify the root cause and eliminate it.

Remember: a properly selected and correctly installed sewage water flow meter will significantly reduce the payment for wastewater disposal in a private area. Since, unlike apartment buildings, where the used water actually enters the sewer, the used water in their own house often finds another refuge. And this is a significant overspending of the family budget to pay for a non-existent service.

|

|

The US-800 ultrasonic flow meter for wastewater and sewerage (household, fecal, domestic and industrial wastewater) is developed taking into account the peculiarities of the operation of metering devices in the Russian Federation, has built-in protection against overvoltage and interference in the network, a stainless steel primary converter!

It is produced with ready-made ultrasonic transducers for diameters: 15, 25, 32, 50, 65, 80, 100, 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1200, 1400 mm!

Specially created and ideal for use by water utilities, sewage pumping stations, housing and communal services, energy, industry!

Sewerage meter US800 is used for accounting of domestic and industrial wastewater, household wastewater.

To account for the volume and consumption of pressurized domestic and waste water, chemical waste, fecal wastewater, in the sewage pumping station, etc., exactly the same sets of flow meters are used as for water accounting

The flow meter for sewage should be installed observing the following rules:

ATTENTION! The main conditions for the correct operation of the US-800 water flow meter are the complete filling of the UPR section with liquid.

In order to avoid possible measurement errors and faults due to the presence of gas or air inclusions, the following recommendations must be followed:

- On very long horizontal pipelines, it is advisable to install the UPR in a section with an ascent angle (see fig.a)

- When supplying or flowing out of liquid by gravity, install the UPR in the lowered section of the pipeline (see Fig. B)

- Avoid installing the UPR at the highest point of the pipeline (see figure c)

- Do not install the UPR on the descending section of the pipeline with a free discharge of liquid to the atmosphere (see Fig. D)

- Avoid the installation of an UPR at the pump suction

- When installing the UPR, orient the probe plane horizontally with a deviation of no more than 25 degrees. (see figure e)

Possibilities of connecting external devices for the US-800 waste water flow meter

Advantages and advantages of US-800

Galvanic isolation the primary converter (pipes) from the electronic unit. THE ONLY FLOWMETER IN RUSSIA !!

- Continuous monitoring of the device's performance and the reliability of the results obtained, filtering and neutralizing interference. Network filter:

- Protection against interference and impulses in the supply voltage, automatic protection overvoltage, overheating. Ultrasonic self-cleaning function for piezoelectric transducers.

- Modern housing with protection against external influences IP 65.

- Reliable connectors.

- The programming keyboard is closed with a hermetically sealed transparent cover.

ALL PRODUCTS ARE CERTIFIED!

| MODELS OF FLOWMETER US-800 | EB serves 1 single-beam UPR, one measurement channel, 2 sensors are embedded on the UPR (1 beam) |

EB serves 2 single-beam UPR, two independent measurement channels in one electronic unit, 2 sensors (1 beam) are embedded in each UPR, it is convenient in multichannel systems, in composite heat meters |

The electronic unit serves 1 double-beam UPR, one measurement channel, 4 sensors (2 beams) are embedded on the UPR, it has an increased accuracy of 0.5-1%, requires a minimum of straight sections during installation. |

|

|

|

| DN 15 to 1400 mm | DN 15 to 1400 mm | DN 50 to 1400 mm |

Delivery set of US-800 in standard configuration:

Description of components: ELECTRONIC UNIT US-800

The electronic unit has a large LED (segment) indicator, which displays flow (m3 / h), volume (m3), time (hour) trouble-free operation of the device.

The electronic unit has a large LED (segment) indicator, which displays flow (m3 / h), volume (m3), time (hour) trouble-free operation of the device. The electronics box is a wall-mounted plastic instrument housing. Supply voltage 220V. Maximum power consumption up to 7 W. Ambient temperature at the installation site from +5 ° С.

Additionally and on request:

Digital interfaces US-800

| Possible digital outputs from the US-800 electronic unit versions 11, 13, 21, 23, 31, 33 |

|

Digital interface RS485 Supports RS485 communication protocols: DCON, Modbus (optional) |

|

| The load capacity of the electronic unit allows combining up to 32 flow meters into one network segment. When using RS485 / RS485 repeaters, the network can be expanded up to 256 units of flow meters. |

|

Description of components:

An ultrasonic flow transducer UPR (with already installed probes probes) is a pipe segment with two flanges welded at the ends, and probes probes are located in the middle part.

An ultrasonic flow transducer UPR (with already installed probes probes) is a pipe segment with two flanges welded at the ends, and probes probes are located in the middle part. Ambient temperature at the place of installation is from -40 to +60 ° С.

For pipes with diameters of 250-2000 mm, kits are also offered without an UPR - with KMCH - sets of sensors and mounting parts for tapping into a pipe (or making a UPR) at the place of operation. The kit with KMCH requires qualified installation!

UPR or KMCH is required in the kit!

UPR are of two types, depending on the number of measuring beams: single-beam and double-beam.

They also differ in the ways of joining ( flanged or welded) and materials of manufacture 12Х18Н10Т (stainless steel) and st20 (black steel): see table below.

| VERSIONS OF ULTRASONIC FLOW CONVERTERS UPR | ||

| SINGLE BEAM insert of a pair of sensors in diameter.

|

TWO-BEAM Insertion of two pairs of sensors along chords. |

Note: Max pressure, Max temperature, Degree of dust and moisture protection. |

| UPR 15, 25 stainless steel 12X18H10T, threaded connection  |

1.6 MPa, +120 ° C, IP65 |

|

| UPR 15, 25, 32, 40, 50, 65 |

UPR 50, 65, 80, 100 stainless steel 12X18H10T, flange connection  |

1.6 MPa, +120 ° C, IP65 |

UPR 80, 100, 150, 200, 250, 300 |

UPR 150, 200, 250, 300 stainless steel 12X18H10T, flange connection  |

1.6 MPa, +150 ° C, IP65 |

|

UPR 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1200, 1400 steel20, flange connection  |

1.6 MPa, +150 ° C, IP65 |

UPR 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1200, 1400 |

UPR 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1200, 1400 steel20, wafer welded  |

1.6 MPa, +150 ° C, IP65 |

| KMCH single-beam. 200-2000

|

KMCH two-beam. 200-2000 pipeless version, UPR not included. Steel 20, kits of mounting parts (lugs, nuts, sensors) for on-site pipe mounting

|

2.5 MPa, +150 ° C, IP65 |

|

Notes: 1) All flange connections can be completed with counter flanges and fasteners (for an additional charge). The material of all flanges is steel 20, flanges are in accordance with GOST 12820-80. Additionally and on request: |

||

Description of components:

CONNECTION CABLE

Connecting CABLE from EB to UPR pipe (up to 500 meters on request).

Connecting CABLE from EB to UPR pipe (up to 500 meters on request).

Coaxial cable 50 Ohm, type RK-50, for connecting UPR and EB.

Cable brand RK-50-2-11.

When ordering a cable, pay attention to the number of sensors on the UPR!

The cable is required!

Description of components:

SUPPORTING DOCUMENTATION

Set of accompanying technical documentation: passport, operation and installation manual, copies of certificates.

Set of accompanying technical documentation: passport, operation and installation manual, copies of certificates.

MAIN TECHNICAL AND OPERATIONAL CHARACTERISTICS OF US-800 FLOW METERS

| The US-800 wastewater flow meter measures the flow rate depending on the nominal diameter of the DN UPR in accordance with the table | |||||

| DN, mm | Volume flow rate, cubic meters / hour | ||||

| Q max maximum | Q p1 transitional T | Q p2 transitional T\u003e 60 ° C | Q min1 minimum T | Q min2 minimum T\u003e 60 ° C |

|

| 15 | 3,5 | 0,3 | 0,2 | 0,15 | 0,1 |

| 25 | 8 | 0,7 | 0,5 | 0,3 | 0,25 |

| 32 | 30 | 2,2 | 1,1 | 0,7 | 0,3 |

| 40 | 45 | 2,7 | 1,3 | 0,8 | 0,4 |

| 50 | 70 | 3,4 | 1,7 | 1,0 | 0,5 |

| 65 | 120 | 4,4 | 2,2 | 1,3 | 0,65 |

| 80 | 180 | 5,4 | 2,7 | 1,6 | 0,8 |

| 100 | 280 | 6,8 | 3,4 | 2 | 1 |

| 150 | 640 | 10,2 | 5,1 | 3 | 1,5 |

| 200 | 1100 | 13,6 | 6,8 | 4 | 2 |

| 250 | 2000 | 17 | 8,5 | 10 | 5 |

| 300 | 2500 | 20,4 | 10,2 | 12 | 6 |

| 350 | 3500 | 23,8 | 11,9 | 14 | 7 |

| 400 | 4500 | 27,2 | 13,6 | 16 | 8 |

| 500 | 7000 | 34 | 17 | 20 | 10 |

| 600 | 10000 | 40,8 | 20,4 | 24 | 12 |

| 700 | 14000 | 47,6 | 23,8 | 28 | 14 |

| 800 | 18000 | 54,5 | 27,2 | 32 | 16 |

| 900 | 23000 | 61,2 | 30,6 | 36 | 18 |

| 1000 | 28000 | 68 | 34 | 40 | 20 |

| 1200 | \u003d 0.034 x DN x DN | \u003d 0.068 x DN | \u003d 0.034 x DN | \u003d 0.04 x DN | \u003d 0.02 x DN |

| 1400 | \u003d 0.034 x DN x DN | \u003d 0.068 x DN | \u003d 0.034 x DN | \u003d 0.04 x DN | \u003d 0.02 x DN |

| 1400-2000 | \u003d 0.034 x DN x DN | \u003d 0.068 x DN | \u003d 0.034 x DN | \u003d 0.04 x DN | \u003d 0.02 x DN |

| Brief specifications flow meter for wastewater (waste water meter) | |

| Criteria for filling the pipeline with liquid | must always be filled with liquid at the measuring point |

| Measured liquid temperature | 0 ... + 120 (+150) ° С |

| Liquid pressure in the pipeline | up to 1.6 MPa |

| Ambient temperature at the installation site | +5 ... + 50 ° С |

| Ambient temperature at the place of installation of the UPR | -40 ... + 60 ° С |

| Degree of dust and moisture protection EB / UPR | IP65 / IP65 (IP68) |

| Length of straight sections (single-beam UPR) 15-2000 mm | 10 DN BEFORE and 3 DN AFTER |

| Length of straight sections (double-beam UPR) 15-2000 mm | 5 DN BEFORE and 1 DN AFTER |

| Supply voltage | 220 V (18-24-36 VDC optional) |

| Indication | 9 familiarity, segment indicator |

| Maximum power consumption | 7 watts |

| Length of connecting cables from UPR to EB | up to 200 meters (up to 500 special order) |

| Calibration interval | 4 years |

| Full average service life | 25 years |

| Guarantee period | 18 months |