Materials for paving garden paths. Paving views. Paving paths with concrete slabs

Paving

Paving - laying out paths, roads, paths and sidewalks with a variety of materials. Paving - this is what the foot steps on, what a bicycle or car will ride on, etc., it is a necessary element of landscaping.

Paving of paths, roads, paths, paving of streets suggests that the main zones, sections of the territory have already been allocated. When deciding what a track should be (length, width, material), the following points should be considered:

This happens as follows: special cold recycling granulates damaged road layers, usually a wear layer and a binder layer and some part of the carrier layer, mixing the granulate with a new binder and immediately reinstalling it.

This method is supported by a short construction time and high economic efficiency. When disposed of “in the factory”, a mobile mixer for cold recycling is usually located next to the construction site. The unit is broken at a construction site with trucks. Finally, trucks deliver the recycled mixture back to the construction site. If the equipment for mixing the cold mixture prepares a cold bitumen mixture with added asphalt foam, then it does not need to be collected immediately. It can be stored for a certain time on the heap, so bitumen should not come from the same building on which it will later be located.

- Operating intensity

- Functional purpose

- Features of the surrounding landscape, its style

- Terrain relief

- Material Properties

Materials that can be used for coating are divided into:

- Soft (crushed stone, gravel, pebbles, brick or granite chips and other bulk materials)

- Hard (stone, paving slabs)

- Combined

Consequently, paving in the end is obtained: soft, hard or combined.

Opinions on the use of destructive milling asphalt layers are different. Some of them are considered as non-hazardous waste in the production of asphalt mixtures. They are considered by others as material that, due to the wide variety of old layers, can reduce the quality of mineral-asphalt mixtures. It is also possible to use it with numerous advantages and without compromising on quality.

Experiments on the use of asphalt granules in apartments

The key to success is a good recognition of the milling surface and testing of asphalt granulate obtained by destructing. The test is carried out by painting the well with special white paint, and the resin resin is painted yellow. In the case of the presence of resin on the surface, the milling material cannot be used to produce the mixture and is automatically disqualified. So, the first test is very simple. An important element is also selective milling and, thus, avoids discrepancies in the results when assessing the uniformity of the granulate.

"Hard" paving

The choice of material for paving depends on the intensity of operation. Paving with tiles, paving paths with stone, paving with granite or some other “hard” pavement is suitable for paths, roads, porches, paths and sidewalks along which intensive traffic resembles.

Paving with paving slabs, granite paving and natural stone paving found wider application than “soft”, as it is easier to care for, stronger, lasts longer and looks quite attractive. Paving slabs and stone are characterized by a sufficient variety of texture, shape and color.

The machine distributes the granulate into two fractions on the sorter - thin and thick, which is then mixed to obtain a homogeneous material. Therefore, to protect the material from moisture and excessive sunlight, it should be stored indoors. The homogeneity of the asphalt granules is checked in the next phase of the test. Evaluation criteria are its particle size, soluble asphalt content and parameters of the restored binding point — softening temperature and penetration rate. The aggregate parameters in the asphalt granules must meet the requirements for aggregates in this mineral-asphalt mixture.

Paving stones made of natural stone is a vivid confirmation of this (a variety of colors, textures). Mostly paving stones are made of granite or sandstone. A big plus is that paving stones, thanks to its unique shape, can bridge both straight and winding paths. The surface of the pavers is recommended to be coated with a special composition that increases the water-repellent properties, strength, light resistance of the tile, and also protects it from chemical solutions and from lime salting.

Benefits of Mixed Granular Production

Granular asphalt can be used in the production of mixtures, provided that all requirements for the finished product are met. Mixing with asphalt granules offers many advantages. One of the most useful factors is the fact that this technology is environmentally friendly. With the reuse of asphalt granulate, we eliminate the problem of the formation of large storage areas of this material in the repair of old sidewalks. Another important aspect is the economic effect.

It is desirable that the paving paving had a smooth, non-slip surface and withstand sufficient loads. When paving sidewalks and roads, it is especially important to think over a drainage and drainage system in advance in order to avoid accumulations of water and other precipitation.

Soft paving

Coatings that consist of “soft” materials are great for paving garden paths. It should be borne in mind that “soft” garden paving quickly loses its shape, especially if you drive on it in cars or some other form of transport. Moreover, such coatings are not easy to clean from debris.

With a proportion of 15-20% of the granulate in the mixture, we can use up to 1% less asphalt. An additional advantage is that asphalt granules improve the parameters of mixtures, such as resistance to tinting and resistance to water and frost. This will make the surface longer for traffic. However, it is important to remember that an asphalt additive can only be used as a base layer and is associated with asphalt concrete. Cannot be used for abrasive and asphalt castings.

Granular asphalt is a fully mixed mineral-asphalt mixture. This material can be used from the construction of urban roads to national roads. Therefore, asphalt waste should not be considered as waste or materials suitable only for hardening roadside roads. Let's take an example from our western neighbors who use up to 70% of the milling material in modern mills when milling granulate using the “hot” method. Let's build our roads to serve us for many years, based on environmentally friendly materials.

"Combined" paving

Paving stone path, supplemented with marble chips or pebbles; paving with paving slabs of “brick crumb islands” ... “Combined” paving opens up limitless possibilities for the creator’s imagination. It is clear that such paving has a decent price, but the result is worth it.

In various shapes and colors. All you have to do is choose with care and what suits you. All this is not very difficult, and now you have more solutions available, choosing from several types of pavers, which, in turn, have many shapes and colors.

If you haven’t laid alleys before and dirt has become a real problem, then it's time to do it. You have a choice, and it's not that complicated. Currently, you have several solutions available, choosing from several types of sidewalks, which, in turn, have many shapes and colors.

Having entrusted the paving of the Zhilekspertiza organization, you can not worry that all the work will be done efficiently, on time, and in accordance with your wishes. Highly qualified specialists will develop a design of any complexity and optimally combine all the materials that you wish.

Master class by Nina TOMILINA

This is one of those materials that adds elegance to decorations and does not hurt over time, but the price is also high if we compare with other materials for sidewalks. However, it should be said that, in addition to the aesthetic part, sidewalks made of natural stone have good stability and have a long service life. In addition, if you use volcanic rock basalt sidewalks with high concentrations of iron or copper, you may have a pleasant surprise that these sidewalks change their color due to the oxidation process.

Keep in mind that this type of pavement has a high price and requires a longer installation time. Granite is quite common when it comes to the sidewalk of the courtyard, which is a hard stone with very good mechanical strength and excellent properties when it comes to the aesthetic aspect. It counteracts the phenomenon of frost very well and is easy to maintain; it can only be washed with water. Manufacturers offer granite pavers in a wide palette of colors and shapes. The price is higher compared to other types.

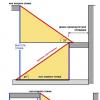

Basic principles of combination and combination of materials

A properly planned network of footpaths in the garden is an important part of creating a beautiful and comfortable garden. We walk along them, enjoying the beauties of the garden, drive a wheelbarrow along them or go with a bucket and a shovel at the ready. Paths are main, walking and secondary, workers. Depending on the purpose, we will build them from different materials. The dimensions of the garden dictate their width: the paths of the main route are from 0.8 to 1.5 m, the auxiliary ones are from 0.4 to 0.8 m, the optimal width is 0.6 m.

Beware of acidic substances that can affect them, given that granite is a slightly porous rock! Marble pavement is equally common in marble. It can be found in many colors and shapes, which will undoubtedly give a sense of elegance to the space next to the house, thereby improving the quality of the sidewalk. Unfortunately, it is less hard and elastic than granite and requires careful and regular maintenance, being vulnerable to scratches.

The most common today are vibropress sidewalks. They have excellent resistance to the freezing cycle and provide good adhesion. The manufacturing process involves casting dry concrete with a hydraulic vibro-compressor that compresses the concrete, eliminating excess water. Their installation is fast enough, the price is affordable and can be found in various shapes and colors. In addition, they do not require winter maintenance or any subsequent maintenance in order to maintain their appearance.

Track pattern can be built on geometric or free landscape lines, a reasonable game of contrast between strict geometry forms and smooth lines is also acceptable, for example, a combination of straight and pictorial lines, diagonals and circles, etc.

Paths and paths divide the site into different zones and at the same time combine the garden into a single space. This is achieved not only by the general pattern of the tracks, but also by the use of carefully selected paving materials. There are several rules for the selection and use of decorative materials, which are applicable not only to create a network of paths in the garden, but also for any other work on the design of our environment.

Among the disadvantages is a lower service life than other materials, and the fact that it is sensitive to acidic substances. Concrete pavements consist of a combination of two ingredients: cement and aggregates. Add color pigments to this mixture to create the color you want. They are designed to withstand extreme weather conditions and heavy traffic areas. They are in different forms, with many nuances. It is recommended to use colored sealing materials for concrete coatings to maintain color longer.

They are cheap, fit easily, but do not exceed the aesthetic side. Brick pavers are made of natural clay, dried in special furnaces at high temperatures. This process gives very good resistance to brick coatings. Over time, they are very durable. Another advantage of brick pavers is color, and clay is a natural material that keeps its color vibrant. This type of sidewalks is in different shades: from dark brown and from dark to red and even from pink shades.

Rule 1. In the paving of the paths that are adjacent to the house, the material used in the decoration of the house itself should be involved, whether it be a facade, a socle or a porch.

That is, the same material should move from the vertical plane of the wall of the house to the plane of the garden and spread over it, which greatly enhances the feeling of the common space of the entire estate. In the paving of the adjacent territory, this material should not dominate, otherwise the house and garden will visually merge. Usually it occupies about a third of the paving area.

They are also available in a wide variety of shapes and sizes. It is easy to install and the purchase price is affordable. This method consists of combining paving lawn, vibropressed paving mainly using a scale, which allows grass to grow in joints or perforated areas, which eventually reach the pavers of the mask and create a green area. Typically, polyethylene will be used for this type of paving, which will then be applied to the lawn. This type of pavement is aesthetic, but requires careful maintenance, the necessary moisture content of the sod and installation of facilities for drainage and drainage should be provided.

Let's analyze a fairly common option. The house is built of red brick, has white window frames, a concrete blind area and a porch. It will be appropriate to decorate the front zone with paving from paving concrete tiles, combining it with a clinker brick pattern. The light gray color of concrete muffles the brightness of red brick, makes it calmer and more pleasant to perceive, in harmony with the white color of window frames, which, in fact, also work to smooth the color of the walls.

As an element of external design, the sidewalk emphasizes the role of each space in the yard and supports the architectural specifics of each project. To find out what type of sidewalk to choose for your project, you must keep in mind several key elements, namely.

Depending on the purpose of each area, we distinguish several types of requests and claims on the selected sidewalk. If we talk about access areas for cars, such as access roads of the plot, parking, then you choose the sidewalk reliable, very durable, able to take on the task, which will be exposed to surfaces. For surfaces intended only for walking, you can select materials to highlight the destination of this area. Here we have in mind the architectural style of the house, the landscape features of the garden and, of course, the area in which the residence is located. The chosen sidewalk must harmoniously fit into the environment and respect the individuality of the house and the owner. Safety factors. Rain or snow can turn an unreasonably paved area into a real danger zone. For the most vulnerable areas, such as terraces, stairs, home driveways or parking spaces, select sidewalks with anti-slip and weather-resistant properties. The areas adjacent to the pools also need a moisture-resistant coating and at the same time anti-slip, so that the area can enjoy the whole family without worries. Maintenance. Choose sidewalks with protection systems both inside and outside the pavers. Such products require minimal maintenance due to the fact that dirt does not stick to their surface, they are more stable and retain their bright colors over time.

- Superficial appointment.

- Aesthetic considerations.

Photo 1

Photo 2

In this case, we select brick brick because it is close in strength to natural stone, while ordinary brick in paving is unstable, it begins to crumble quite quickly, especially if it is laid flat and not placed on an edge. But the combinations and patterns of clinker and concrete tiles can be a great many, just try to pick the clinker and concrete tile more or less the same size. In this case, paving from mixed materials will be stronger ( photo 1, 2, 3).

Photo 3

Photo 4

Suppose a path near the house or around it will be laid out from concrete paving slabs with the inclusion of clinker or finishing the sideline from it. Then we will switch to paving only from concrete slabs, possibly of a different size or shade with rare clinker inlays ( photo 2), and subsequently, as we move into the forest zone, we will finally remove the clinker from the paving, reduce the proportion of concrete slabs and introduce gravel backfill. In some sections of the path remote from the house, gravel backfill can be made with the inclusion of separate, different in tone concrete slabs ( photo 4) As you move deeper into the forest, concrete can completely disappear from the road surface.

Photo 5

Photo 6

However, the materials with which we laid out the paths near the house will reappear when we come across a forest trail bench in a small resting area or fountain with cool water. We can pave such a site with concrete paving slabs with a clinker pattern, reminiscent of paving of a house adjoining territory, but simpler. And we can just make gravel filling all over the site and surround it with one or two rows of clinker ( photo 5, 6) Here the reverse solution is also possible: if the brick walls of the house and the fence remained in the distance, then it is possible to put a brick in the basis of paving, and enter concrete tiles or gravel backfill only as a small recollection of the path traveled ( photo 3).

Thus, combining carefully selected paving materials is an effective technique that combines the entire composition of the garden. Moreover, in each zone of the garden, paving must correspond to the purpose and style of the zone itself, whether it is a forest arbor or an economic area.

Minor or garden walkways can be made of concrete paving slabs 30 x 30 cm in size, laid in two rows, or from two types of tiles, for example, in the first row of the track, two tiles of 25 x 25 cm are laid out, and in the second row - only one tile of 25 x 50 cm in size, and these rows alternate . If you want to reduce the width of the secondary track, then tiles of 25 x 25 cm in the first row are laid out next to each other, as in the previous version, and in the next row the same tiles are laid, but in the middle, etc., that is, the tiles are laid according to the brickwork principle, when one top brick lies on the bottom two. The last two options for laying tiles do not have cruciform seams ( photo 7).

Photo 7

This paving method is worth a closer look. Most sites in the Moscow Region are located on flooded medium and heavy loams. The soil is constantly saturated with water that does not leave. With the onset of frost, the water in the soil freezes and, as you know, expands. The soil is expanding accordingly. Such soils are called heaving soils, they cause a lot of trouble for builders, landscape designers, and site owners. It is clear that such soils can lift the tiles laid in the track, and it is the tiles that have cruciform joints that are easiest to lift, and tracks with other types of joints are less deformed.

Photo 8

There are a sufficient number of developed layouts for rectangular tiles. The most decorative is the so-called roman masonry (photo 8), which uses tiles of several sizes, they are laid out in a free pattern, but without cruciform seams. In Western Europe, this type of masonry is extremely popular and is made of rectangular and square stone slabs.

Minor paths can be laid out in the technique of a step-by-step path, when the plates are laid with gaps corresponding to the step length. The gaps between the plates are filled with turf or loose decorative materials. It’s convenient to walk along such a path, you can carry a wheelbarrow along it, while the lawn does not suffer ( photo 9).

Photo 9

Rule 3. In the design of paths and playgrounds in the garden, you can use no more than three different, but combined materials and no more than two or three of their shades.

However, the layout of these materials can be very diverse. Indeed, the monotony and uniformity of paving must be violated by interspersing tiles that are different in tone, texture, or introduce green islands from unpretentious ground cover plants resistant to trampling, which organically look on paving.

From these rules, it becomes clear that the materials for the decorative and functional design of the site cannot be randomly selected.

Another standard option, requiring the selection of completely different materials, is wooden house, and this may be an old village house, and a house on the garden plot, and a modern cottage made of glued or rounded timber. I’m sure the reader already understood that one of the materials for decorating the site will be a tree. These are all kinds of floorings, walkways, shields of various sizes, garden parquet, step paths from saw cuts of various sections and diameters, tinted beams and just old railway sleepers ( photo 10), recessed in a lawn or gravel bed, and, finally, decorative bed of wood bark and wood chips.

Photo 10

Wood as a material for creating tracks not yet often used in our garden design. Usually, natural stone is preferred. However, it is wood that is the main building material that fits perfectly into the landscape, while natural stone, which, undoubtedly, is the most durable and expressive decorative material, is not such an unequivocal leader in garden improvement. There are no rock outcrops in the nature of the Moscow Region, so the excessive use of stone in decorating gardens is not completely natural.

Tinted wood is beautiful, durable, environmentally friendly, pleasant to the touch, quickly gathers solar heat, dampens the sounds of steps and makes the pedestrian look under his feet and admire the simplicity and naturalness of the material familiar to us from childhood. We all remember the silver-gray fence of the grandmother’s fence from the weather, but it will only stir up long-forgotten memories of low-type summer cottages with carved platbands, painted shutters and an octagonal attic window in old summer cottages that remained in an old era ... And in other countries, progressive designers artificially age, bleach wood, giving it exactly that unique silver-gray shade, using complex tinting, or specially put garden furniture in gardens without any protection They are waiting for several years when it will get exactly the same shade ...

Photo 11

Long-term use of wooden flooring and walkways in the open air is possible subject to a number of rules. Firstly, you can buy products of Western companies that produce wood materials with a ribbed non-slip surface, from which they make floorings, patios, walkways and square panels, placed in a step-by-step order. They are extremely durable, since under factory conditions antiseptics are driven into this wood under high pressure ( photo 11) However, such wood is very expensive. Of the more accessible species can be called larch. It is durable, but not cheap. Oak for such purposes is not suitable for everyone, since it is also expensive, and serves no longer than pine. Most consumers buy pine. With proper wood processing and preventive care, such floorings can withstand 8–10 years without major repairs.

For flooring usually use boards with a thickness of 15-30 mm and a width of 200-250 mm. The entire surface of the wood is treated with an antiseptic, and those parts that will come in contact with the ground are covered with bitumen.

Wood flooring and walkways must be kept in constant ventilation mode, i.e. raise above the ground, putting on its legs. The bar serves as legs with a section of 40x80 mm. Of course, the legs are treated with bitumen. Typically, wooden walkways are two boards connected by transverse rails and placed on legs. Between the boards leave a gap of 20–25 mm, which contributes to additional ventilation. The surface of the boards should be well processed, the parts of the walkways are connected using galvanized bolts with recessed heads. On such a flooring, you can walk barefoot without fear of injury. It dries quickly and heats up under the sun, gives pleasant warmth to the feet.

Wooden garden elements require annual treatment with antiseptic agents, if possible, it is advisable to remove them indoors for the winter. Such bridges are located on a gravel bed. They are often thrown over a dry stream, lead from one wooden flooring to another, they are widely used in natural or natural gardens. Wooden shields and walkways often lead to water bodies and even go out onto the supporting surface of the pond.

Photo 12

The same rules apply to construction. wood end walkways (photo 12) Typically, the beams are cut 15–20 cm long, impregnated with an antiseptic, the part that will be in the ground is treated with bitumen and installed in a roadbed on a layer of compacted sand. The gaps between the segments are filled with sand and compacted. In large gaps, you can hammer segments of a smaller diameter, previously sharpening the lower end. You can decorate the gaps with wood bark or wood chips.

When working with wood trimmings, you can use this technique: not short cuts are buried in a predetermined place, but 0.5 m long elements - such protruding processed logs can serve as seats or support for a bench on a walking forest route. If you deepen a group of logs 1.0-1.5 m high, you can get a decorative wall or garden sculpture, organically inscribed in the plane of the path and as if “growing” out of it.

Despite the fact that decorative wood materials are quite diverse, it is not entirely correct to use only them when designing a site with wooden buildings, especially if the site is large enough. Wood materials combine well with natural stone, with warm tones of gravel, with artificial tinted concrete and porcelain tiles.