The boiler is a combined gas solid fuel. Combined boilers: design features. Solid fuel and electricity boilers

Combined boilers heating, unlike traditional heating units, can work with various heat carriers. This versatility is ensured by design features - the presence of several combustion chambers (for each type of fuel).

For the operation of boilers, gas, electricity, liquid fuel - diesel and solid fuel for boilers - firewood, coal, peat briquettes and pellets.

But what is condensation heating? How does it work and what can it provide as a partner in solar thermal energy? The best way to understand what condensation heaters are is step by step. First of all, it is important to determine what fuel is and what is the fuel value of fuel.

Literally any chemical that releases the energy stored in it when it burns, which can then be converted into usable energy, is the so-called fuel. Also, the way a fuel releases its energy can give a rash to a unit. Chemical fuels release their energy through oxidation, so that thermal energy is generated. Electrochemical fuels are used in fuel cells, where they produce electricity. The ultimate differentiation option for fuels is fossil fuels and renewable raw materials. Qualitatively, fuel can be estimated using calorific value.

Types of combined boilers

There are several modifications of the equipment:

1. A two-fuel boiler is a conventional heat exchanger into which a burner is installed. In models that use electricity, heating occurs with the help of heating elements (a boiler works by this principle).

With which we are approaching condensation technology one step closer. Calorific value is an indicator of the specific heat of a material that contains a substance. It refers to block sizes. Good to know: the calorific value corresponds to the absolute value of the standard enthalpy of combustion of general thermodynamics, which is given a negative sign.

The energy of a fuel, such as wood, gas, or oil, is associated with its associated chemical energy: the enthalpy of the reaction. To do this, it is released to a temperature of 25 degrees Celsius during condensation of the fuel and then cooling the combustion gases. On the one hand, the calorific value takes into account the energy necessary for heating combustion air and exhaust gases, and on the other hand, the so-called enthalpy of condensation of liquids generated during cooling and condensation of combustion gases. First of all, we are talking about the enthalpy of condensation of water, which is formed during the combustion of hydrogen-containing fuels.

2. A combined boiler with three types of fuel allows you to heat the house with almost any fuel. A set of such a boiler includes several burners and combustion chambers.

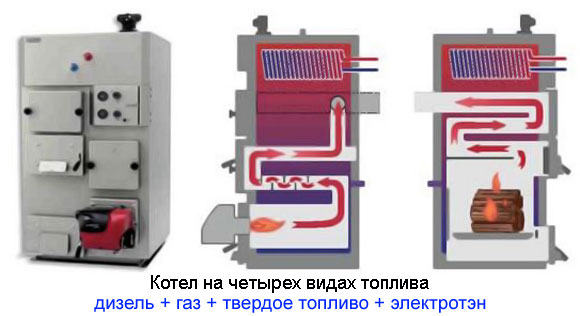

3. A four-fuel boiler is considered universal. Additional burners, as a rule, have to be purchased independently.

Excursion: Calorific value is not always equal to calorific value

In other words, the value of condensation takes into account the use of the heat of condensation of water, which evaporates in the flue gas. Calorie content should not be confused with calorific value. Calorific value refers to the maximum amount of heat consumed by combustion, depending on the amount of fuel used, without condensation of the water vapor contained in the combustion gases. The calorific value is the “energy content” or “energy value” of the fuel, although this does not exactly reflect what the calorific value really is, it is usually called: a measure of the specific amount of useful material without condensation heat.

note

The following coolant combinations are possible: diesel + gas; diesel + gas + electricity; diesel + gas + firewood; diesel + gas + electricity + firewood.

How to choose the right model?

Combined boilers are indispensable in areas where there is no centralized power supply and interruptions in the supply of any one energy source are possible.

We can also say that the calorific value is precisely the energy that is released during combustion and subsequent cooling to the initial temperature of the combustible mixture, and the combustion water remains gaseous. Thus, the calorific value of fuels that have relatively high proportions of water is much lower than its calorific value, namely, the magnitude of the enthalpy of condensation of real water vapor.

Only for fuel that is completely dry and where hydrogen is not chemically bonded has a calorific value that is equal to a calorific value and vice versa. The calorific value is given in different physical quantities depending on the total state of the fuel.

For heating country houses or cottages most often use a boiler type firewood + gas or electricity + firewood.

When choosing a combined boiler, you must decide which energy source will be used most often:

- Gas boilers are simple and economical, but their stable operation requires a pressure of 3.5 mbar. At lower pressures, their effectiveness decreases.

- For the operation of an electric boiler, a constant stable voltage in the network is necessary, which is rarely the case in the private sector. It is best to use such boilers in parallel with gas or solid fuel models.

- Gas + firewood heating boilers require constant attention, since such models provide minimal automation of the process and safety control. For the same reason, boilers are relatively cheap.

note

Fuel Burning - A Look at the Burning Process

This brings us closer to condensation technology. When hydrocarbons are burned, for example, natural gas, oil, coal or wood, the oxygen from the combustion air combines with the hydrogen contained in the fuel, resulting in water vapor. Conventional technology, in particular heating technology, allows the exhaust gas generated by combustion, and thus the water vapor contained therein and the energy stored therein, to avoid non-use through the chimney. And we are almost where we wanted: condensing technology as a modern standard in heating technology.

Also, it should be assumed that 1 kW of thermal power is needed for 30 m 3 in a well-insulated room.

- If the function of the boiler should include only heating, a single-circuit boiler should be selected, if it is planned to heat water - a double-circuit. The latter can be of two types: with a built-in coil and a boiler.

Advantages and disadvantages

Combined boilers have the following advantages:

Calorific value technology makes almost full use of the condensation value of fuel

On the other hand, modern condensation technology is able to condense water vapor contained in the exhaust gas through a suitable heat exchanger, so that the condensation heat contained in the smoke is substantially restored. Thus, the so-called condensing boilers use the "energy content", better: the fuel value of the fuel is almost complete. They cool the exhaust gas and thus create the heat of condensation of water vapor in the flue gas. It has better combustion efficiency than conventional, older combustion technologies.

- there is no need to be attached to a certain type of fuel;

- the ability to connect multiple heating circuits;

- in the absence of electricity, you can switch to another type of fuel;

- such a boiler is able to fully satisfy the domestic needs for hot water;

- if necessary, a boiler can be installed;

- equipment is environmentally friendly;

- has good efficiency;

The price of wood-fired boilers is much lower than the cost of boilers with alternative fuel sources. In terms of economy, they are considered the most profitable.

How does condensation heating work?

Finally, let's take a closer look at the principles of condensation technology. Since the acid condensate generated during firing fuels attacks the “base” materials, and previously used boilers and extraction pipes were not protected, that is, corroded, the boilers were designed so that condensation did not occur in the boiler. This worked due to the high temperature of the boiler 70 degrees Celsius or more. And since, in particular, long chimneys will be sabotaged by subsequent condensation, the goal was to ensure that the exhaust gases were at least 120 degrees Celsius hot when they passed the chimney.

Despite a number of advantages, there are some disadvantages of combined boilers:

- models running on electricity / gas have a fairly high price;

- need a special room for storing firewood;

- maximum power of combined boilers does not exceed 35 kW.

If the boiler model runs on gas or electricity, it is necessary to develop a project and obtain permission from the relevant authorities. Particular attention should be paid to safety:

This means that if a modern condensing boiler is used in the existing heating system, the draft must be adapted to the colder nature of the exhaust gas. A cold chimney will act as a flow cooler, in which the cooler exhaust gas condenses. As a result, the chimney can be severely damaged, it will be humidified, impregnated and irreparably damaged.

Combine stool to use pellets and logs at the same time. Therefore, all heating systems that allow heating more than one type of fuel are designated as a combined boiler. Wooden gasifiers Combined chairs are not only available for burning logs and pellets. In addition to systems for burning various wood fuels, there are also boilers for combined heating with wood and oil or gas.

- The boiler can only be installed on a concrete base.

- It is necessary to plan the chimney and regularly clean it.

- The boiler must be in a well-ventilated area.

- To switch to another type of fuel, just change the burner.

Popular manufacturers

1. Kiturami (South Korea). Most of the models operate on 2 types of fuel and are equipped with two circuits. Boilers are designed for heavy loads and work in any climatic conditions. To heat a house of 300 m2, approximately 2.2 tons of raw materials per month will be required, provided that the boiler will work 8-9 hours a day.

It is enough for me to load the hopper once every few days, and the pellets are automatically fed into the combustion chamber.

There was a situation when our power was turned off ... And nothing, I put the emergency grate and loaded pellets in the traditional way. And yet, in this boiler, a program for the hot water system is installed, which allowed us to use hot water even when the boiler did not work due to lack of light.

The only thing is the limited ability to use raw materials. Therefore, I began to think about combined boilers, but so far I have not decided anything.

Wooden gasifier combined with multiple combustion chambers

Thus, wood gas is formed in the uppermost combustion chamber, which completely burns in the middle combustion chamber to produce heat. Here, at the top of the wood boiler, there is a double combustion chamber with two separate sections for pellets and logs. Then the gas is supplied to the common lower combustion chamber and, with good efficiency, the wood gasifier burns completely to produce heat.

- For example, a boiler with three combustion chambers is possible.

- The two upper chambers act as a wood gasifier for logs.

- The lower combustion chamber is then used to heat with pellets.

- Alternatively, this combustion chamber may also be installed for gas or oil.

- An alternative is a common wood gasifier for pellets and logs.

- Both fuels are burned to produce wood gas.

Thus, the combined gas-wood boiler is one of the most affordable types of heating country house. The device is trouble-free in operation, does not require special training in maintenance, is safe and environmentally friendly.