Minimum floor screed: calculation of the amount of materials

In order to save money, some craftsmen make a screed on their own. Therefore, such questions as "what is the technology of forming the coating?", "What materials are required?", "What is the minimum thickness of the floor screed?" considered relevant. In this article you will find the answers to them.

In order to save money, some craftsmen make a screed on their own. Therefore, such questions as "what is the technology of forming the coating?", "What materials are required?", "What is the minimum thickness of the floor screed?" considered relevant. In this article you will find the answers to them.

What is a screed? This is the basis (basis) of the floor, on which the finishing coat is installed without any problems. It will not be easy without it when making repairs at the present time. This applies both to floors in old houses (Soviet-era buildings did not differ in functionality and high quality), and in new ones.

What is a screed for? It is intended:

- For creating slopes in the floor area.

- To distribute an even load on the floor.

- To form a very flat base.

- To ensure sufficient strength (dynamic and static) of the formed system.

The screed must:

- be durable to easily withstand loads of 15 MPa and more;

- have minimal deviations in the density of the layer thickness;

- have a high-quality durable surface without visualized defects;

- the slope should not be more than 0.19%.

What materials are needed for the minimum acceptable floor screed?

- To arrange the base, concrete (cellular and lightweight) and cement-sand mortar, as well as ready-made ones, are suitable. The material is selected based on their own justified preferences, taking into account the available surface quality. Cement-sand or classic concrete screeds are usually leveled with an additional mixture (for example, under parquet). However, an additional leveling layer is not needed when tiling.

- Dry mixes are very common in construction practice. These formulations are packaged from 25 to 50 kg. The price falls in proportion to the increase in volume. Choose a mixture that is designed specifically for the screed device. It is advisable to give preference to successful, proven brands. Be careful, low-quality products come across quite often.

- You can also use an all-purpose or masonry mix. Take a close look at the shelf life of the composition and its color. In dry form, the cement-sand mixture has a gray color. There should be no reddish-brownish tinge. If there is one, then there is an abundance of sand in the mixture. To correct this defect, simply add water to the solution.

Cement-sand classic mortar is easy to prepare yourself. The main thing is that the cement is at least 400 grade, the sand is quartz, and the ratio of one to three is observed. To make the solution homogeneous, first, the materials must be mixed dry and only then add water.

If you strictly adhere to the methodology, then in the final version the mass will become two hundred brands. The lower the grade, the more water.

A few words about concrete. Quite often, foam concrete (from class B3 and above) is used for the screed device. It can be monolithic, with a density of 600-1000 kg / m³, or in the form of slabs. Cellular and lightweight types of porous concrete have good thermal insulation properties. However, they will require additional alignment. You can read the material about.

The best result is given by foam concrete. Here the thermal conductivity is lower, the average density is, and the surface is smoother. And yet, due to the high level of fracturing, experts advise placing an additional layer of cement and sand screed on it.

Minimum floor screed thickness. What is it like?

Many craftsmen are worried about this indicator. Indeed, in some cases, exceeding the norm, an emergency situation may arise. For example, if you will, do not overdo it, trying to make the floors higher than the room, since more than one base will not withstand such a mass.

Summing up, it should be said that in each case the minimum thickness of the screed can be most reliably determined only individually. It all depends on the conditions:

- what materials the screed is made of;

- laying the screed on the floor slab or insulating layer;

- under what covering the screed is prepared.

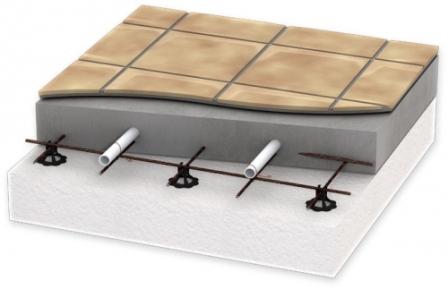

The screed can be laid both on the installed heat and sound insulation layer and on a solid concrete floor. In these cases, the thickness of the formed screed more than 4 cm is unacceptable. And you need to make reinforcement (use "Fibrin" or a metal mesh). In the bathroom or in the renovated kitchen, the waterproofing layer must be done in the same way.

The size of the bar should be one and a half meters. With these tools, it is enough to walk along the floor to determine if there are holes between the floor plane and the level. If, however, there are minor dents and holes, the floor should be leveled. Naturally, you should not neglect the screed either. Its thickness varies within three to five centimeters.

The opinion is erroneous: the thicker the forming sub-base, the stronger the screed. Its purpose is to level the floor, and not to raise the floor area by half a meter.

In addition, simply pouring a certain composition onto an uneven surface is not enough. If the thickness of the screed is made unreasonably larger, then it will dry for a very long time. Naturally, this will create unwanted inconveniences for you. the site reminds you that only after the sub-base has completely dried, you can proceed to the installation of the topcoat. How to determine if this moment has come? A quick glance is enough - the floor became hard when it took on a light gray shade.

When is a cement-sand screed used?

If you need to eliminate irregularities not exceeding two centimeters. And since many compounds contain, the thickness of the screed, respectively, should be about three centimeters. If the screed nevertheless turns out to be thinner, then it will certainly be covered with cracks. Experts generally insist on a thickness of five centimeters so that water from a carefully prepared solution does not evaporate too quickly.

There are also cases when the level differences exceed six centimeters. So the slabs were laid somehow. the site recommends in this case to use sand concrete screed. In its composition, not ordinary, but coarse-grained sand is used. The thickness indicator of such an underlay should not exceed one and a half centimeters. When the drops reach simply exorbitant values, this figure can rise to 170 millimeters. The main thing is to put expanded clay concrete under the screed, otherwise its cost will cost a pretty penny.

If the differences and inevitable roughness are insignificant (less than twenty millimeters), the site recommends giving preference to leveling mixtures. The term "screed" here can be replaced by the concept of "interlayer". As for the minimum and maximum permissible thickness, the manufacturer has the last word for each composition.

- If you are on a layer of insulation, leave a small gap of forty millimeters between the wall and it. This cavity must be filled with insulating filler. Experts advise separating monolithic screeds from the walls with special waterproofing films.

- The screed should be twenty millimeters thick if you are working on floor slabs. If the work is carried out on a layer of insulation, then this figure rises to forty millimeters. If there is a need to mask the pipeline, the thickness of the described layer should be at least ten centimeters.

We hope you understand that the thickness of the screed varies (slightly) depending on the conditions and requirements of SNiP. The installation also has its own peculiarities.

Screed thickness for underfloor heating

Understand that when installing underfloor heating, the concrete screed will be a heat-distributing material. Especially when it comes to a water-heated system. Therefore, in order for the final result to be of high quality, choose either an ordinary cement-sand mortar or a fast-setting mixture (you can buy it in packaged form).

For underfloor heating, the minimum screed thickness is three centimeters above the pipe surface. If necessary, it can be higher, but in this case it is necessary to take into account the characteristic correction factors and carry out additional calculations of the thermal regime for the heated room area. A thickness of seven to ten centimeters is the best indicator. Three to five centimeters is the norm for an electrical floor heating system.

It is important to consider the time it takes for the surface to dry and harden. Under normal conditions, it depends on the type, thickness of the screed and the materials used to prepare it. If the classic cement-sand mortar was used under parquet, then it will take thirty days to harden: a week for each centimeter + for each subsequent centimeter for two to three weeks.

But it is better to mount ceramic tiles on a screed ten days after pouring it.

Remember, leveling and self-leveling building compounds harden differently: from twenty-four hours to four weeks. It all depends on the polymer additives used in the composition of the material.

What is the optimum thickness of the floor screed to form?

Leveling the floors can fairly be considered an important process. Therefore, it is undesirable to neglect it, especially in a residential area. When laying the formed floor on the installed joists, the described procedure will be superfluous. The thickness of the screed for conventional pouring is very different from the thickness of the screed for underfloor heating. So, for a water system, a cement layer of at least seventy millimeters is required, but no more than ten centimeters. The electrical system can also be hidden under a five centimeter thick screed.

Acceleration of the aging (drying) process of the fill due to the activation of the underfloor heating system is contraindicated. This will significantly reduce the strength of the screed.

More precise individual parameters for the screed:

- above the water system - from seven to ten centimeters;

- above the electrical system - from three to five centimeters.

The hardening time of the thickest of these screeds reaches one hundred and forty days. Check the heating system in advance for integrity and performance, especially when it comes to the water floor.

When the screed has practically hardened, the system can be activated again for a short time so that the remaining moisture evaporates in the depths of the solid concrete layer.

Secrets of a smooth screed (video)

Can a floor screed be calculated using a calculator?

When planning to carry out repairs, you definitely know the individual characteristics of the area to be restored. That is, you already know the approximate operational load on the existing floor. A high thickness of the cement layer (at least seven centimeters) is required for the kitchen and living room, hallway and corridor.

Reinforcement can be used. Then the thickness of the fill will not exceed four centimeters. It is better to achieve high strength of the coating in the children's room. In this case, the thickness of the screed should not be less than five centimeters.

Based on these approximate parameters, the only answer to the question "how to calculate the screed for your apartment?" will be: the height of the layer must be the same everywhere. If you want to get a solid, durable base for the topcoat or if you are installing a warm floor system, then the thickness of the cement should be five to six centimeters. If you consider that you will still lay the reinforcing layer, this will be enough. Doorways should also be a reference in the calculations, because strong raising of the floor can reduce their height. In this case, you will have to install door leaves of a special standard.