Types of electrical cables, wires and cords

The main types of cables and wires used for installation in an apartment or a private house should be considered in more detail (Fig. 4.22). Careful information is required when purchasing, installing, operating and repairing them. It is used for transmission and distribution of electric current, operating voltage - 660-1000 V, frequency - 50 Hz. The number of cores can vary from 1 to 5. The cross section is from 1.5 to 240 mm 2. In a domestic environment, ka is used linen with a cross section of 1.5-6 mm 2, in the construction of a private house - a cable with a cross section of up to 16 mm 2. The veins can be either single or multi-wire (Fig. 4.24). There are no restrictions - you can put a cable with a cross section of 10 mm 2 in the apartment. |

Power cables

Among the most popular types of cable products in recent years, VVG cable and its modifications can be called.

VVG denotes a power cable with PVC insulation, PVC sheath (cambric), copper core material, which does not have external protection (Fig. 4.23).

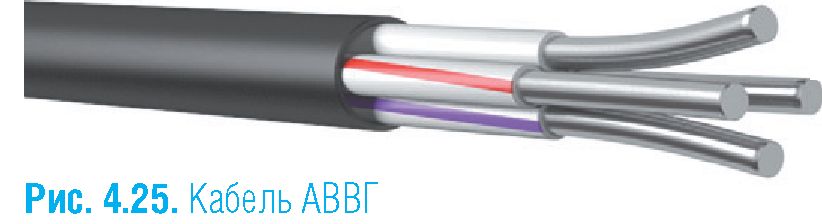

VVG is used in a wide temperature range: from -50 to + 50 "C. Withstands humidity up to 98% at temperatures up to +40" C. The cable is strong enough to break and bend, resistant to aggressive chemicals. When installing, remember that each cable or wire has a certain bend radius. This means that for a 90 ° C turn in the case of VVG, the bend radius must be at least 10 cable cross-sectional diameters. In the case of a flat cable or wire, the width of the plane is considered. The outer shell is usually black, although sometimes white can be found. Does not spread combustion. TPG insulation is marked in different colors: blue, yellow-green, brown, white with a blue stripe, red and black. The cable is packed in bays of 100 and 200 m. Sometimes there are other sizes. Varieties of VVG: AVVG - the same characteristics, only instead of a copper conductor, an aluminum one is used (Fig. 4.25); Conductor PVC insulation PVC sheath

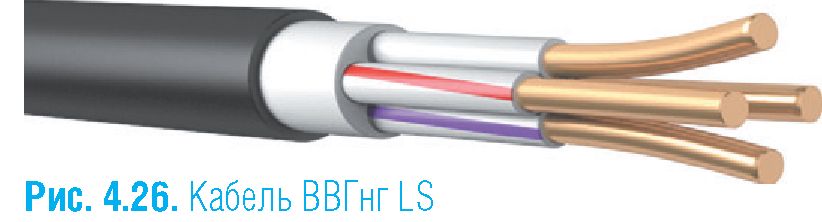

VVGng - a cambric with increased incombustibility (Fig. 4.26);

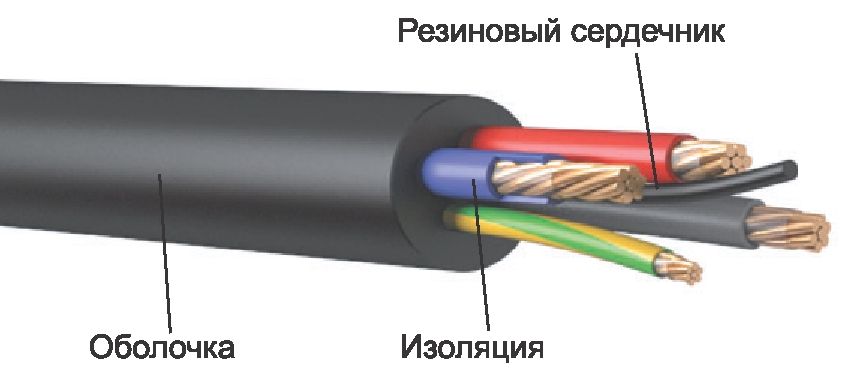

VVGp - the most common variety, the cable cross-section is not round, but flat; VVGz - the space between the TPZh insulation and the cambric is filled with PVC harnesses or rubber compound. NYM does not have Russian decoding of the letter designation. This is a TPG PVC insulated copper power cable with a flame retardant PVC outer sheath. Between the layers of insulation there is a filler in the form of coated rubber, which gives the cable increased strength and heat resistance. The veins are multi-wire, always copper (Fig. 4.27). The number of cores is from 2 to 5, the cross section is from 1.5 to 16 mm 2. Designed for lighting and power networks with a voltage of 660 V. It has high moisture and heat resistance. Can be used for outdoor installation. Operating temperature range - from -40 to +70 "C. Disadvantage: Does not withstand exposure to sunlight, so the cable must be covered. Compared to any type of VVG, it is more stable and convenient to work with. However, there is only a circular cross-section (it is inconvenient to lay it in plaster or concrete) and is significantly more expensive than VVG. Bending radius - 4 cable cross-section diameters. KG stands for very simple - flexible cable. This is a conductor with an operating voltage of up to 660 V, a frequency of up to 400 Hz or a constant voltage of 1000 V (Fig, 4.28). |

Copper conductors, flexible or with increased flexibility. Their number varies from 1 to 6. TPZh insulation - rubber, outer shell of the same material. The operating temperature range is from -60 to +50 "C. The cable is mainly used to connect various portable devices. Most often these are welding machines, generators, heat guns, etc. There is a variety KGng with non-combustible insulation. NOTE KG has perfectly proven itself precisely as a cable that works under almost any outdoor conditions. At a construction site, it is simply irreplaceable for pulling power lines. Although some original people, attracted by the flexibility and reliability of the KG, mount it as a home wiring. The latter are both single-wire and multi-wire. The number of cores is from 1 to 5. The cross section is from 1.5 mm 2 to 240 mm 2. TPG insulation, outer jacket, space between insulation and cambric - PVC is used in all these places. Then comes the armor of two tapes, wound in such a way that the outer one overlaps the boundaries of the lower turns. Over the armor, the cable is enclosed in a protective PVC hose, and in the VBBShvng modification, this material of low flammability is used. VBBShv is designed for alternating rated voltages of 660 and 1000 V. Single-core modifications are used to conduct direct current. Lay in pipes, ground and outdoors with sun protection. Operating temperature range - from -50 to +50 "C. Moisture resistant: at a temperature of +35 ° C withstands a humidity of 98%. It is used when conducting electricity for stationary installations, as well as supplying electricity to detached objects. The bending radius is not less than 10 cross-sectional diameters VBBShv is perfect for underground supply of electricity to a detached building. AVBBShv - cable with aluminum conductor; VBBSHvng - non-combustible cable; VBBShvng-LS - non-combustible cable with low gas and smoke emission at elevated temperatures. Wires |

PBPP (PUNP) refers to installation, or assembly. The wire is flat, with single-wire copper conductors covered with PVC insulation, the outer sheath is also made of PVC (Figure 4.30).

Rice. 4.30. PBPP wire |

The number of cores is 2 or 3, the cross section is from 1.5 to 6 mm 2. It is used for laying stationary lighting systems, as well as for mounting sockets, although it is preferable to use it for lighting. Rated voltage - up to 250 V, frequency - 50 Hz. Operating temperature range - from -15 to +50 "C. Bending radius - not less than 10 diameters.

PBPPg (PUGNP) differs from PUNP in veins - they are multi-wire (Fig, 4.31). That is why the letter "g" is added to the name of the wire - flexible.

All other characteristics correspond to PUNP, only the minimum bend radius is 6. A distinctive property is flexibility, therefore, PUNP is laid in places where the wiring makes frequent bends, or for connecting household appliances to the network. Wires of these brands are sold in bays of 100 and 200 m. The color is usually white, less often black.

The type of PUNP is a wire with aluminum conductors APUNP (fig, 4.32). He has exactly the same characteristics as PUNP, adjusted for the material of the core. The only difference is that APUNP cannot be multi-wire, and therefore flexible.

NOTE

In general, wires of the PUNP, PUGNP and APUNP brands have perfectly proven themselves as household wires. In half of the cases, the master has to deal with them. However, it should be remembered that these brands of wires are highly specialized, and you should not use them instead of power cables (such as NYM or VVG).

ATTENTION!

The popularity of PUNP and PUGNP wires is based primarily on the price. However, there is a catch in this. The fact is that recently a discrepancy has been noticed between the declared cross-section of the conductors of the wire and the actual one. After checking, it turned out that the wire labeled PUGNP 3x1.5 is actually 3 x 1 - that is, the actual cross-section of the core is less. The same goes for isolation. When buying wires of this brand, it is necessary to measure the cross-section of the conductors and the thickness of the insulation.

400 Hz. The wire is resistant to aggressive chemical environments, non-combustible, has a wide operating temperature range - from -50 to +70 "C. Moisture resistance - 100% at a temperature of +35" C. The bending radius when laying is at least 10 wire cross-sectional diameters. Resistant to mechanical damage and vibration. APPV has the same characteristics as PPV, with the exception of the core material - it is aluminum (see Fig. 4.34). APV - aluminum single-core wire with PVC insulation (rice, 4.34). Round wire, single-wire core with a cross-section from 2.5 to 16 mm 2 and stranded - from 25 to 95 mm 2.  The wire is used in almost all types of installation of stationary lighting and power systems. It is laid in cavities, pipes, steel and plastic trays. It is widely used in the installation of switchboards. Chemically resistant, operating temperature - from -50 to +70 "C. Moisture resistance - 100% at a temperature of +35" C. Bending radius - at least 10 diameters. Resistant to mechanical damage and vibration. The appearance and characteristics of PV 1 in everything coincide with the AR, except for the material of the core: instead of aluminum - copper (Fig, 4.35). The conductor cross-section starts from 0.75 mm 2.  In addition, the core becomes stranded not from 25, but from 16 mm 2. More flexible than AR. The characteristics of PV 3 wire coincide with the properties of APV and PV 1. Scope of application - installation of sections of lighting and power circuits where frequent bending of wires is required: in distribution boards, when installing a large number of electrical devices. It is also used for laying electrical circuits in cars. Bending radius - not less than 6 wire diameters (fig, 4.36).  |

The vein is multiwire, their total number ranges from 2 to 5, the cross section is from 0.75 to 16 mm 2. Rated voltage - up to 380 V, frequency - 50 Hz. The core insulation is color-coded and the sheath is white.

The wire is used to connect various electrical devices, from household appliances to garden tools. Due to its flexibility and lightness, it is also used for lighting and even installing sockets. PVA is a household wire used for the manufacture of extension cords, cords for any type of equipment and repair of power grids. It is non-flammable (does not spread combustion with a single gasket), heat-resistant: temperature range - from -40 to +40 ° C (version of PVA U) and from -25 to +40 "C. Thanks to its design, it is resistant to bending and mechanical wear. can withstand at least 3000 folds.

Ball screw - copper or copper-tinned flat wire (rice, 4.38). Core insulation and PVC sheath.

Rice. 4.38. ShVVP wire |

The core is multiwire, with increased flexibility. The number of cores is 2 or 3, the cross section is from 0.5 to 0.75 mm 2. Voltage - up to 380 V, frequency - 50 Hz. It is used as a cord for connecting lighting fixtures and household appliances of low power, for example, soldering irons, mixers, coffee grinders and electronic devices.

NOTE

ШВВП is a wire exclusively for household needs, it is not used for wiring lighting or sockets.

Cables for transmission of information

In addition to electricity, cables aregive informational signals. In onrecently there have been manynew types of information conductors.If 10-15 years ago there wereonly telephone and antenna cables, thennow with the development of computer technicknames of types of information wirenicknames have become much more. Bolshinsome of them are too specializedand is of interest only for narrowlyprofile specialists. For homeit is enough for him to know and be able touse only a fewmi. We will consider them.

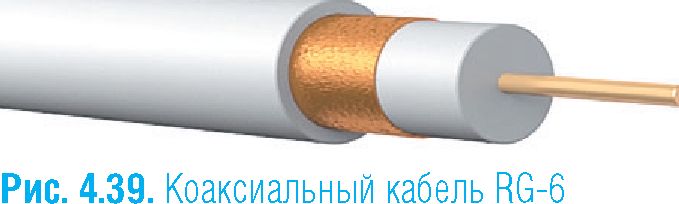

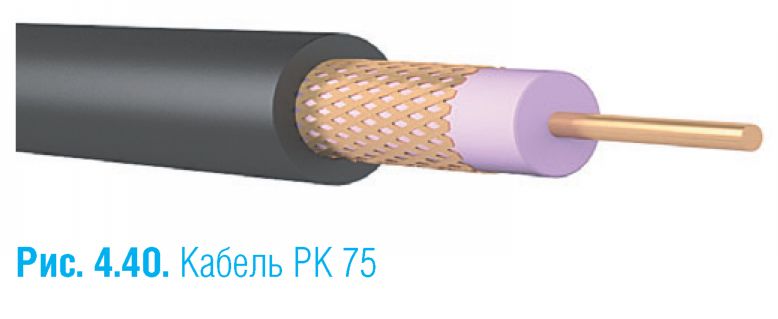

Antenna cables. Today day most often used RG-6,RG-59, RG-58 or Russian counterparts series RK 75.

RG-6 - coaxial cable for netransmission of high-frequency signals forelectronic equipment, televisionor radio (fig, 4.39).

Consists of central copperconductors with a cross section of 1 mm 2, surroundingits insulation made of foamed polyethyleneLena, aluminum foil screengi, tinned outer conductorcopper braid and PVC sheath.Widely used for transmissionsignals from cable and satellitetelevision. Has a variety of techniquestechnical characteristics concerning teafrequency of the transmitting signal, resistanceremoval, shielding, etc. For example,designation in the name of the cable RK 75means that the resistance of the wireka - 75 Ohm (rice, 4.40).

This information is intended for professionals. In short, we can say that this cable is ideal for transmitting a video signal from an antenna or video camera to a receiver (TV) and distributing the video signal to several sources (Fig. 4.41).

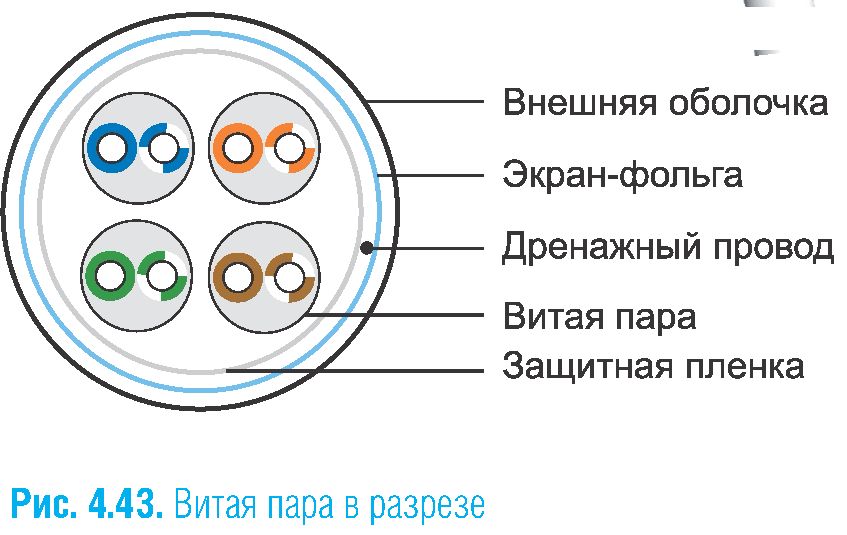

receiving or transmitting a signal. Each conductor is enclosed in PVC or propylene insulation. The outer sheath is also PVC. The cable can be additionally equipped with a moisture-proof polypropylene sheath. There is a breaking thread in the twisted pair design. With its help, the outer sheath can be easily removed from the cable, opening access to the conductive cores.

RG cables have many varieties and differ from each other in some characteristics, for example, conductor resistance, resistance to temperature and shock loads, signal decay time, type of shield, etc. (Fig.4.42). Computer cables (twisted pair). Serve for building computer networks (Fig. 4.43). The cable by which computers connect to the Internet or to each other is just a twisted pair (Fig. 4.44 and 4.45). Consists of one or more pairs of wires, twisted in pairs, which is done in order to improve Depending on the type of cable, various protection options are possible:? UTP, or unprotected, without common shield for wire pairs; FTP, or foil, with an aluminum foil screen; P STP, or shielded, with a common copper mesh shield, in addition, each twisted pair is surrounded by a separate shield;

|

Rice. 4.45. Tip RJ-45 for connecting to a computer

Rice. 4.45. Tip RJ-45 for connecting to a computer

S / FTP, or foil, shielded with common screen out foil, in addition, each pair is additionally enclosed in a screen. In addition, twisted pairs

/divided into categories by the number of pairs combined into one cable. The most common type used for computer networks is a category riya SAT5e. It consists of 4 pairs of wires of different colors. Data transfer speed - up to 1 Gb / s when using all pairs.

You can see such a cable used as a CAT1 or CAT2 telephone wire, that is, consisting of 1 or 2 pairs of wires.

Telephone cables and wires

Telephone conductors are divided into 2 main types. The first ones are intended for laying several (up to 400) subscriber lines. The second type is used for wiring in a separate apartment or house.

TPPep - the main type of cable for laying a line designed for a large number of subscribers (Fig, 4.46).

The cable consists of two wires twisted in pairs. TPZh made of soft copper wire, with a cross section of 0.4 or 0.5 mm 2, covered with polyethylene insulation. In some types of cable, pairs are combined into groups of 5 or 10 pairs. The outer sheath is also polyethylene or vinyl. The letters "e" and "and" in the title denote a film screen. There are varieties of cable, armored with tapes, or filled, in which the space between the sheath and the cores is occupied by a hydrophobic seal. In a word, this is a cable for conducting telephone communication in an apartment building, it is intended for laying in almost all conditions: underground, in cable channels or by air.

To lay a telephone line to an individual subscriber and wiring indoors, the following telephone wires are used of two types.

TRV- one- or two-pair telephone distribution wire (Fig, 4.47).

Rice. 4.47. Telephone TRV wire

Rice. 4.47. Telephone TRV wire

This is a flat wire with folddivided base, livedcopper, single-wire, ce0.4 or 0.5 mm 2. Quantitynumber of conductors - 2 or 4. Insulation fromPVC. Designed for indoor telephone lines.

Operated at the same temperature from -10 to +40 ° C. Humidity should not exceed 80% at temperature+30 ° N

TRP - according to its characteristics, it coincides with the expansion valve. The only difference is insulation, for TRP it is made of polyethylene (Fig, 4.48).

Rice. 4.48. TRP wire

Possessing increased resistance to environmental influences. Such places include baths, stoves and cellars. In general, wherever it is too hot, humid or cold, and in addition, there is a possibility of mechanical damage. It is clear that PVA or VVG cannot be installed in such places, not to mention PUNP or SHVVP.

RCGM - power assembly single-core wire of increased temperature resistance, flexible. Copper conductor, multi-wire, cross-section from 0.75 to 120 mm 2. Insulation made of silicone rubber, fiberglass sheath impregnated with heat-resistant enamel or varnish (rice, 4.51).

Rice. 4.51. The wire RCGM

This wire is designed for rated voltage up to 660 V and frequency up to 400 Hz. Resistant to vibration, high humidity (up to 100% at a temperature of +35 ° C), heat-resistant (operating temperature range from 60 to +180 ° C). In addition, the wire is protected from the harmful effects of varnishes, solvents and mildew. Perfect guidefor rooms with povahigh temperature (boilers and stoves), suitable for electrical installation in baths, saunas, oven connections.

PNSV- single-core heating wire. TPZH single-wire steel, blued or galvanized steel (rice, 4.52).

Rice. 4.52. The wire PNSV

Conductor cross-section - 1.2; 1.4; 2 and 3 mm 2. Insulation in PVC or polyethylene. Rated voltage up to 380 V, frequency 50 Hz. The wire is thermo-resistant: operating temperature range - from -50 to +80 ° С, resistant to alkalis and moisture resistant (transfers immersion in water). It is used as a heating element: in domestic conditions, warm floors are mounted using PNSV.

Runway - single core copper wire. The core is multi-wire, enclosed in polyethylene insulation, sheath is also made of polyethylene or PVC (rice, 4.53).

Rice. 4.53. The wire Runway

The cross-section of the conductor is from 1.2 to 25 mm 2. Rated voltage - 380 or 660 V, frequency 50 Hz. The wire is resistant to pressure changes. Operating temperature range - from -40 to +80 ° С. It is used for motors of artesian wells submerged in water under high pressure conditions.

LED cablea very interesting option for power. Additionalwires with sequentialsolidly connected

LEDs of different colors. They are located at a distance of 2 cm from each other, they burn with a constant sufficiently strong light (Fig, 4.54).

Such a cable performs not only decorative functions, although it can be used to create whole light pictures. In addition to aesthetic purposes, it is very convenient for connecting to portable electrical mechanisms. Most often, LED cable is used to connect stage equipment. It is useful in that when a rupture occurs, it is not necessary to look for the place of damage: the diodes in this area will stop glowing. Such cables are manufactured by Duralight. In addition to power conductors, there are computer glowing cables.

In addition to LED cables, there are electroluminescent ones. They glow evenly along their entire length. With the help of such cables, you can create glowing inscriptions and even whole paintings. This is a great alternative to the flexible neon tubes that are commonly used for such designer jewelry. In addition, electroluminescent cables are cheaper than neon tubes and are not limited in length.

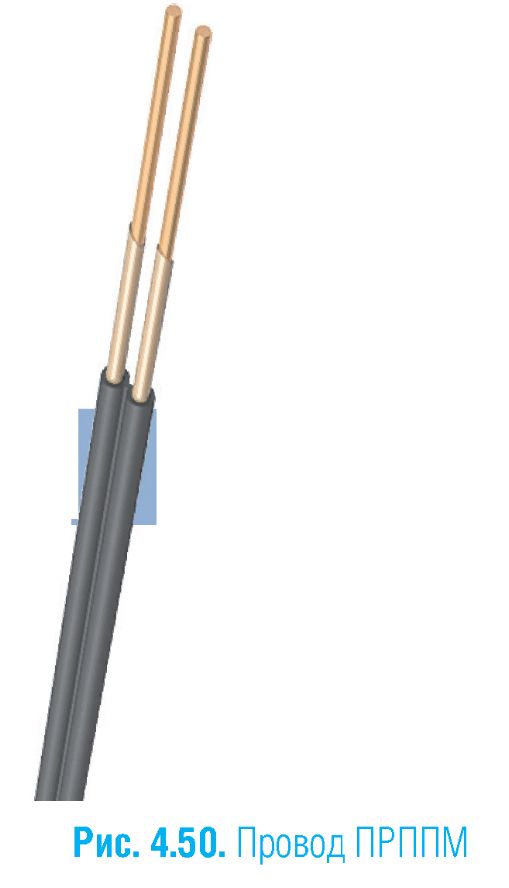

It is used for conducting lines indoors and in telephones. Highly flexible wire. Rppm - flat wire with a separating base and single-wire copper conductors with polyethylene insulation and sheathing (Fig. 4.50). There is a modificationPRPVM, the shell of which is made of PVC. Number of cores

It is used for conducting lines indoors and in telephones. Highly flexible wire. Rppm - flat wire with a separating base and single-wire copper conductors with polyethylene insulation and sheathing (Fig. 4.50). There is a modificationPRPVM, the shell of which is made of PVC. Number of cores

Special types of cables and wires

For the installation of electrical systems in places where conditions are very different from usual, special cables are used,

Compared to the expansion valve, the wire is more resistant to the external environment and can be laid outside buildings. SHTLP - telephone flat cord with stranded copper conductors. Polyethylene core insulation (Fig. 4.49). Insulated TPG covered with PVC sheath. The number of cores is 2 or 4, the cross section is from 0.08 to 0.12 mm 2.

|

Rice. 4.44. Twisted pair

Rice. 4.44. Twisted pair