What about fasteners? General purpose fasteners

Modern fasteners

IN last decade New construction technologies have come to us from abroad and along with them modern construction, cladding and insulating materials. Unfortunately, much less is known about modern fasteners in our country.

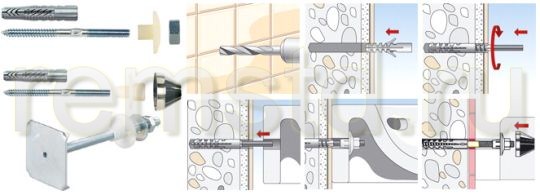

General purpose fasteners

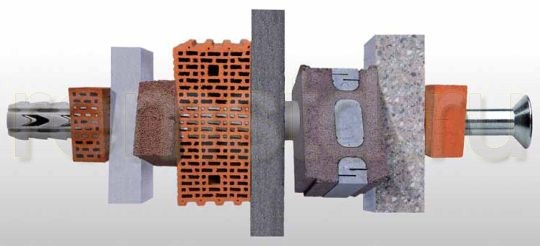

Designed for fastening to any building structures made of concrete and brick - solid and hollow (from hollow brick to hollow aerated concrete blocks). The fasteners include a dowel and a screw for wood or chipboard.

Hollow material fasteners

Used for fastening light elements - lamps, shelves, baseboards, switches, cornices, hangers, pictures, etc. to hollow (thin-walled) structures, such as plasterboard, gypsum fiber sheets (GVL), chipboard, sheet steel, hollow profiles , ceilings with voids, hollow doors, etc. The fastener consists of a special dowel for hollow materials and a screw.

Dowels for insulating materials

Designed for mechanical fastening of hard and soft insulating materials in the form of a panel or sheet (stone wool, glass wool, polystyrene, polyurethane, polystyrene foam, fiberboard boards, coconut fiber mats, cork, etc.) on a plane of concrete, lightweight concrete, natural stone, solid and hollow bricks, hollow blocks and aerated concrete. For installation of some models of such dowels, additional nails and screws are not required. Other models come complete with a steel expansion nail. Leading fastener manufacturers use for these purposes only galvanized and passivated (with additional coating) steel nails with increased strength to bend.

Dowels for aerated concrete

Already from the name itself it is clear that they are designed specifically for attaching windows, doors, grilles, consoles, pipelines, to building structures made of aerated concrete. suspended ceilings, structures made of wood and metal, cable routes, plumbing equipment, etc. They are used complete with a locking screw made of galvanized and passivated or stainless steel.

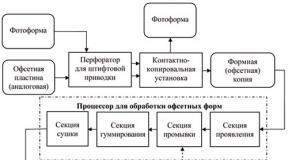

This is the most modern class fastening systems. They are designed for mounting parts on structures made of heavy concrete, dense natural stone and other dense materials of equal strength in cases where it is required increased level reliability and safety (including for fastening facade cladding and load-bearing structural elements - traverses, consoles, etc.). The principle of operation of chemical fastening systems is based on filling the prepared hole with a special two-component mixture, which, when hardened, “tightly” fixes an anchor or threaded rod in the hole (the outward end of the rod looks like an ordinary threaded rod). The mixture is in a glass cartridge, which is inserted into the hole. After this, a rod is screwed in, which crushes the glass, and the mixture fills the entire volume of the hole.

Injection fastening systems

They are a type of chemical fastening system. The difference lies in the method of filling the hole - in in this case by directly squeezing the mixture out of the cartridge, similar to the use of sealants. Such fasteners are used for the installation of gratings, fences and railings, pipelines, plumbing fixtures, etc. Depending on the material of the building structure - hollow or solid - the system is used with or without an anchor sleeve, respectively.

Used for fastening sinks, urinals, bidets, wall-hung toilets, water heaters to wall structures made of concrete, natural stone, solid brick, solid gypsum boards, hollow blocks, aerated concrete (there are special models designed for fastening to walls made of plasterboard, gypsum fiber boards, chipboard) . This fastener includes a dowel, a galvanized and passivated steel stud, a nylon flange nut and a metal decorative cap. Toilet fasteners are designed to secure toilets to concrete floors. It consists of a dowel, a brass screw, a locking sleeve and a decorative cap.

Fasteners for balcony structures

Designed for fastening wooden balcony cladding, polymer materials and metal, general cladding, small pieces of equipment, wire ties, building elements etc. to structural elements of balconies. Simply put, such fasteners are designed for fastening to thin-walled metal elements from which the balcony fence is assembled (pipes, profiles, sheets, panels and slabs several millimeters thick). The fastening consists of a nylon spacer with a collar, a brass screw and a decorative cap.

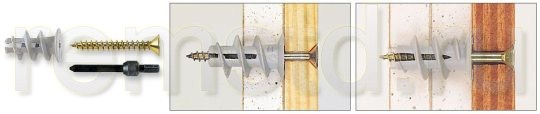

Frame fasteners

Designed for fastening frames, joining wall and plaster profiles, wooden parts (including plaster lathing), skirting boards, wall corners, cable ducts, cable and pipe clamps, etc. The fastener consists of a special frame dowel and an expansion screw.

Designed for invisible fastening of wooden steps to concrete or metal profiles, solid brick, natural stone. The fasteners include: a nylon dowel with a shoulder for fastening to solid materials or a nylon spacer cartridge with a shoulder for fastening to thin-walled structural elements, a brass or galvanized and passivated steel screw, a core for accurately marking holes in the board. Such fasteners can be used not only for stair steps, but also for invisible fastening of any other wooden elements.

Dowel clamp

Designed for fastening individual cables, flexible pipes or cable harnesses to building structures made of concrete, solid sand-lime and clinker bricks, natural stone, lightweight concrete and aerated concrete.

Cable and pipe clamp

Designed for rational fastening of cables and pipelines to building structures. The clamps themselves are attached to the structures using dowels and screws. These clamps are available in various sizes, each equipped with a special element that allows the clamps to be fastened together.

Fastener selection

When choosing fasteners, you need to remember that this is a very serious and responsible matter. After all, furniture, lighting fixtures, technical designs, which are attached to the walls and ceiling, are usually located higher than human height (in any case, higher than the height of a child). At the same time, even not the heaviest of them (say, a picture or a sconce), if it breaks from its fastening, can cause very serious injuries. What can we say about a hanging cabinet or bookshelf that has fallen off the wall? Therefore, the main advice: if you want to feel calm and safe in your own home, use only fasteners from leading global manufacturers. Installation is a responsible matter, and the quality of your repair depends on how it is carried out. In order to choose the right fasteners (with the help of tables you can easily select fasteners, depending on the material used) and learn about new fastening systems, you can view catalog of Fischer fastening systems 2014.

Modern fastening systems are a guarantee of high-quality and reliable fastening

At the end of June 2017 in Germany, the Fischer Group, a world leader in the field, received the “Special Trust” award (“Stein im Brett”), becoming No. 1 in the field of construction fasteners. The main criteria for obtaining highly appreciated steel product quality, price, ease of installation, desire to recommend products to others. The award was awarded based on the results of a survey of builders and sales representatives. The questionnaire included 297 suppliers of construction equipment in 26 product categories.

The ease of installation of Fischer products was especially noted. This is most recognized important aspect in the daily work of builders and one of the main reasons why craftsmen recommend to each other fasteners from this particular German manufacturer. In order to continuously improve products and simplify the installation process, Fischer specialists regularly organize meetings with installers and builders, as well as with representatives of trading companies. “After all, only those who work with our products every day help to find solutions to various construction problems on various sites and can truly judge the quality of products and services, as well as the level of the manufacturer,” comments Ralf Haefele, Managing Director of FischerGermany Sales GmbH.

The study was carried out during 3000 master classes by the ibau information center. The purpose of the survey was to determine the “particularly revered” brand and the best manufacturer in the construction industry. “This survey is the largest and most significant in German trade,” said Sven Homann, Managing Director of ibau. The study was carried out with the support of the marketing agency Heinze and the online platform Helden am Bau.

*, but we still haven’t figured out what and with what, all this beauty is attached. Now the time has come to talk about the types of fasteners for construction profiles, and in general about construction fasteners in general.

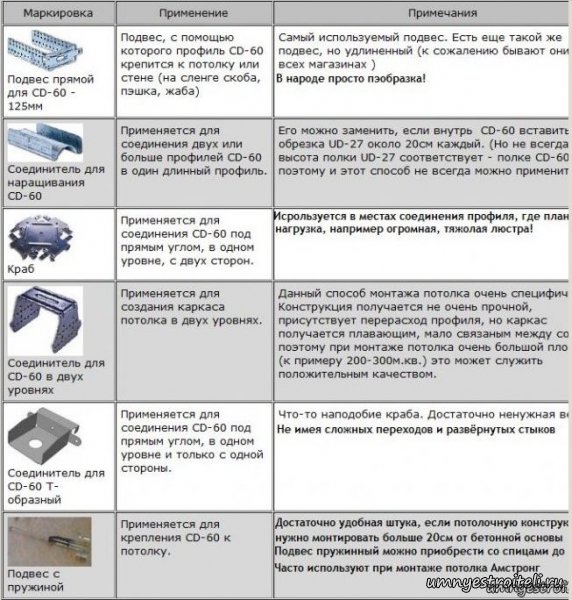

As part of the material, we will discuss auxiliary parts for installing the profile: straight hanger, extension connector, crab, U-shaped connector, T-shaped connector, spring hanger. We will not ignore the fixing and mounting types of fasteners, how profiles and all types of fasteners are screwed on: quick installation, press washers, LM self-tapping screws (flea beetles, bugs, mandavos), self-tapping screws for drywall, wood, metal screws, * and much more. The article on types of fasteners will be supported by photos and videos. There will also be a link to a funny story that happened to us on one weekday.

Auxiliary types of fasteners for mounting the profile in the photo.

This is the picture in which there is different types construction fasteners: straight hanger, extension connector, crab, U-shaped connector, T-shaped connector, spring hanger.

I won’t say that when decorating walls, I use them all. Let’s assume the connecting type of fastener is crab, I use it only when I need to hang a chandelier in the center of the room, connect profiles for the second tier of the ceiling, on the facade, where increased load is expected. I never use a connector for the second tier of a plasterboard ceiling; I normally make do with a suspension (a kind of pendant). Yes, and a special profile extension as such is not needed! It’s quite possible to get by with the rest of the profile instead of buying this extension cord.

The T-shaped connector was actually the first time I saw it in this photo when I started writing the article and was digging through the fasteners for construction.

Apparently all these types of fasteners for * are made by engineers who only in theory know the entire process of installing a profile and it only seems to them that all this will help when assembling the frame. Or maybe our people are used to making do with improvised means!

Now the time has come to talk about how to attach the same peobrazki, crab, profile hangers. That is, we will talk about types of mounting fasteners or fasteners.

Mounting, clamping types of fasteners for profiles and auxiliary elements.

So we have come to clamping types of fasteners for building profiles, which in turn are different. Let me remind you again: quick installation, press washer, LM self-tapping screw (flea beetles, bedbugs, mandavos), self-tapping screws for drywall, wood, metal screws, all kinds of moths. First of all, we will discuss this type of installation as a self-tapping screw for metal and wood.

Self-tapping screws for metal, wood and metal profiles.

Self-tapping screw for metal used when installing drywall to a profile; it is a clamping, fixing type of fastener. This type of screws comes in different lengths: 20-25-30-35-40-45, etc. Used for attaching drywall to the profile. Mainly used on thin-layer metals. The most popular self-tapping screw is 20 mm long.

Self-tapping screw for metal used when installing drywall to a profile; it is a clamping, fixing type of fastener. This type of screws comes in different lengths: 20-25-30-35-40-45, etc. Used for attaching drywall to the profile. Mainly used on thin-layer metals. The most popular self-tapping screw is 20 mm long.

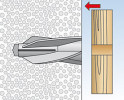

Self-tapping screw for wood, its name speaks for itself. Used for fastening wooden products. Differs from a self-tapping screw for metal, with a wider screw pitch. It can also be used on a metal profile, but it fits much worse into metal. It has more powerful characteristics and all thanks to its screws.

Another self-tapping screw for wood, when working with a frame, is needed only in cases where work on installing a UD profile is being carried out on plaster walls or gypsum partitions. It is also used when attaching a second layer of drywall to the first.

Self-tapping screw for plastic profile, another type of self-tapping screws. It is a decorative clamping type of fastener. So it comes with a self-tapping screw for wood that has a chrome-plated yellow color. Used in furniture.

Type of fastener: LM self-tapping screw (LM, flea beetles, bugs, mandavos).

This type of fastener, with a screw threaded head, LM self-tapping screw (popularly fleas, bugs, mandavos) is one of the main fasteners of subsystems  frame from the profile and it is with these small self-tapping screws that they are screwed on, joining the entire profile together. And of course, using an LM self-tapping screw, all types of profile mounting elements are screwed to the profile: straight hanger, extension connector, crab, U-shaped connector, T-shaped connector, spring hanger.

frame from the profile and it is with these small self-tapping screws that they are screwed on, joining the entire profile together. And of course, using an LM self-tapping screw, all types of profile mounting elements are screwed to the profile: straight hanger, extension connector, crab, U-shaped connector, T-shaped connector, spring hanger.

It is with these small fleas that you can drill through metal as thick as 0.5 mm without any problems. You can read about this in the article -.

There is a story about this small but very powerful montage, nicknamed bugs. which happened in our team, with one of our painters. This story You can read it at the link *.

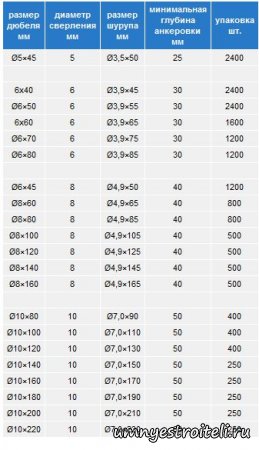

Types and characteristics of fasteners quick installation, popularly BM.

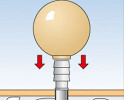

Types of fastening the profile to the wall, or rather, it alone performs quick installation or, as it used to be called, dowel and nail. This mounting fastener has one task: to firmly press profiles, U pieces, corners, etc., to the wall, floor, ceiling, in general, everything that needs to be fastened so that it does not dangle.

Types of fastening the profile to the wall, or rather, it alone performs quick installation or, as it used to be called, dowel and nail. This mounting fastener has one task: to firmly press profiles, U pieces, corners, etc., to the wall, floor, ceiling, in general, everything that needs to be fastened so that it does not dangle.

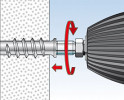

Quick installation consists of two parts. The first part is the threaded nail itself, which can be hammered or twisted, and the second part consists of a nylon plug, which is inserted into a prepared hole of suitable diameter. Under the pressure of the screw, the plug bursts into the wall.

Quick installation is available different models, which are distinguished by the thickness and length of the cork, as well as the length and thickness of the nail.

A table with characteristics and dimensions will be presented below. For a detailed look, click on the picture, it will enlarge.

A table of characteristics showing the dimensions of existing plugs, screw size, drilling diameter, minimum anchoring depth.

A type of clamping fastener is a press washer.

The press washer is also designed to connect the metal parts of the frame from the profile and attach many decorative and finishing materials to the press washers:  corrugated sheeting, siding, alucobond, metal tiles, etc. They have proven themselves very well when working with thin and medium-thick metals that can be easily drilled. Thanks to its wide head, it has a fairly large surface grip, which is very convenient when working, all with the same siding and is good when working with *.

corrugated sheeting, siding, alucobond, metal tiles, etc. They have proven themselves very well when working with thin and medium-thick metals that can be easily drilled. Thanks to its wide head, it has a fairly large surface grip, which is very convenient when working, all with the same siding and is good when working with *.

To be more objective, the press washer is designed for external works. The press washer itself is less susceptible to rust and, thanks to its cap, practically does not allow water to pass through.

Roofing press washers currently come with rubber bands.

Moths as one of the types of clamping fasteners.

A moth is one of the types of clamping fasteners that is used in extreme cases. Only in cases where you need to hang something on a wall or ceiling, where the base is one centimeter thick and has a cavity. For hollow structures such as plasterboard. That is, an ordinary installation, say, like B.M., will not be able to cope in such a situation, since it has a shelf at its “head”, where nothing expands, and as a result, it has nothing to fix it with.

A moth is one of the types of clamping fasteners that is used in extreme cases. Only in cases where you need to hang something on a wall or ceiling, where the base is one centimeter thick and has a cavity. For hollow structures such as plasterboard. That is, an ordinary installation, say, like B.M., will not be able to cope in such a situation, since it has a shelf at its “head”, where nothing expands, and as a result, it has nothing to fix it with.

The principle of operation of the installation is a moth, or as it is also called a butterfly, due to the principle of its opening, to open up in the void. Let's create a larger bonding area behind a sheet of drywall, which will relieve point pressure on the fragile material and distribute it more smoothly in place.

It is better, of course, to avoid fastening with moths, but to install metal parts in advance.

Video on the topic of how to choose self-tapping screws from the variety offered.

Types of driven construction fasteners.

Hammered construction fasteners have always been and remain popular. but only more and more in private houses. Since it is mainly used only on wood. The fasteners that are hammered in were and remain nails, big or small, it doesn’t matter. Anchor bolts and umbrellas are also considered hammer-in fasteners, but let’s talk about everything in order.

Driven fastener nail.

Well, who doesn’t know what nails are used for? There is only one and the most logical answer:

Well, who doesn’t know what nails are used for? There is only one and the most logical answer:

Why nail one piece of wood to another!

There are thin, thick, long and short, hardened and not. Lately nails, in general, like plasticine, are no match for old nails.

There are ordinary ones for woodworking, and there are also slate nails with and without an elastic band.

There is an interesting way of hammering nails into a fence picket to make it more difficult to pull out. You need to drive the nails in unevenly, but slightly at an angle. Only in this way will a picket fence nailed down be much more difficult to simply pull out from the main beam.

Small nail.

When hammering them into the door leaf, the head of the nail may be bitten off and in this form the platband is fixed with them. In order not to damage the casing itself, use this nail. without a hat, they finish off with a cap. After which this small hole in the platband is painted over or covered with a special putty for wood.

This nail can also be used for nailing seals on wooden doors. They also nail down wooden baseboards and baguettes, but this is already considered a thing of the past. More and more people are switching to glue.

It is widely used by those who repair shoes, but this is a completely different topic.

Type of hammered fastener umbrella.

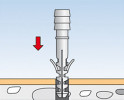

Umbrellas, or combs as they are also called, are used mainly when working with hanging soft and medium-density insulation. Well, let’s say you need to hang foam plastic or something else * on the facade, a construction umbrella will help us with this.

Thanks to its fairly large hat, it perfectly absorbs the load of material. Having a long driving rod, it can penetrate deep into the material into walls. The longest umbrella I saw was forty centimeters.

A construction umbrella consists of a mounting part into which a wedging nail made of the same plastic is inserted. The nail wedges the end of the mounting part, which expands into the wall or ceiling, depending on where you drive it. Thanks to this feature, it can be used on thin-layer partitions, the main thing is that the end of the installation, where it diverges, hits the rigidity.

The anchor is like the last one to be driven into the installation.

Anchors are one of the most powerful hammer-in types of fasteners. Thanks to him, the entrances are installed and held tightly *. thanks to one  of the varieties of anchors, the spokes of ceilings * and other ceilings are attached to the suspension system.

of the varieties of anchors, the spokes of ceilings * and other ceilings are attached to the suspension system.

There are short and long ones, with a bolt that is turned with a wrench and with a special head, which is designed for a bat, a drill or a screwdriver.

The operating principle of the anchor is based on the principle of quick installation. Bottom part when the bolt is screwed in, it expands, but is much stronger, since it is all made of steel. Convenient and easy to use.

Those anchors that come with a nut are considered an outdated option and cheaper, which is why they are still included in the standard set for *.

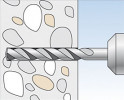

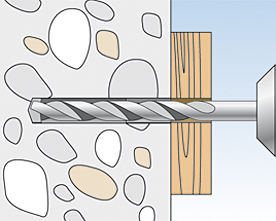

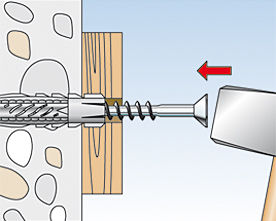

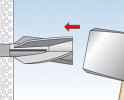

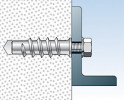

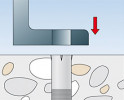

The direct purpose of this category of fasteners is fastening to a wide variety of building structures (concrete or brick) of a hollow or solid type. The main parts of general purpose fasteners are dowels and screws. The last element is also used for fastening to wood, chipboard, plasterboard, glass and other materials.

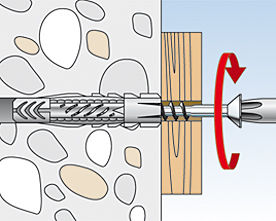

Fixation of the fastener is carried out due to compression/expansion forces that arise when the dowel is placed, for example, in a wall or ceiling. At the same time, for a spacer to occur, a screw must be screwed into it. It can withstand decent loads. (tables with loads are presented in the product descriptions). But in order for the fastening to be reliable, you must know how to install the dowel correctly. In addition, it is necessary to take into account that it is always subject to the destructive force created by the fixed part, since it tends to pull it out of the hole. This is especially true if the attachment point is subject to dynamic loads.

The scope of application of such fasteners is quite wide. They are used for hanging and fastening a wide variety of light-weight elements. These are lighting fixtures, shelves, electric meters, switches, baseboards, hangers, flower pots and so on. Moreover, they can be attached to solid and hollow structures made of:

- plasterboard or gypsum fiber sheets

- sheet steel

- natural stone

- tree

- aerated concrete and so on

General purpose fasteners can be used both in the field of professional construction and in domestic conditions. The line of universal fastening devices is represented by a large assortment of plastic and metal products.

It is worth noting that one of the most famous and well-established manufacturers is Fischer. Its specialists work tirelessly to develop new and improve the reliability of existing fastening devices. A high quality Each fastener is confirmed by a certificate of conformity for dowels.

How to choose the right fasteners

Before choosing a dowel, you need to know exactly what surface the installation will be made to.

Expansion dowels are from Fischer models, and are made from high-quality nylon. Due to the fact that they are equipped with special locking elements, such fasteners cannot rotate in the holes and provide more reliable fastening strength. They can easily be used when working with concrete, brick structures, natural stone and other durable materials.

Before choosing the right dowel, it is worth deciding and clarifying the strength of the material. For example, for fastening to a surface with a low density, the metal expansion dowel Fischer FMD, which is made of galvanized steel and does not require a special (special) tool, is perfect for fastening it.

Before using dowels, it is also necessary to take into account the temperature conditions at which the fastening will be used. Thus, the Fischer M nylon anchor sleeve is treated with fiberglass, and therefore is ideal for use at temperatures from -40C to +80C. This fastener can fasten metal structures on concrete surfaces.

And one more important point When determining which dowels are best, it is the surface thickness. So, for example, when installing elements to floor slabs with a small thickness, it is most convenient to use Fischer PA 4 and dowels made of brass. Their small length and dimensions, as well as knurling and threading, provide increased fixation.

Fisher TS plastic door travel stops and elements used to secure Fisher TB steps have proven themselves to be good. Although they are made of plastic, they are easy to attach to concrete surfaces, steel profiles and hollow surfaces.

How to work with dowels?

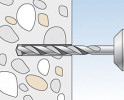

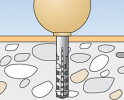

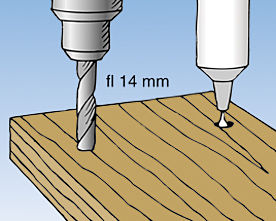

To calculate the required length of the fastener, it is necessary to sum up the anchoring depth and the thickness of the attached structure. If drilling is done in a hollow brick or aerated concrete surface, then you need to know which drill to use for the dowel. For this, drills of various diameters are used. In this case, the hammer drill must have its impact mode turned off.

To comply with safety regulations, it is not recommended to use nylon dowels in structures that are subject to tensile loads. It is for this reason that such dowels cannot be used when attaching lighting fixtures to the ceiling.

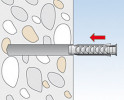

How to insert a dowel into a wall correctly?

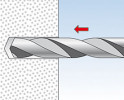

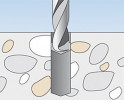

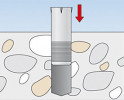

First you need to prepare all the tools. Before driving in the dowel, you should make a mark at the planned fastening location. Then you need to make a small depression. This is done so that the drill can be placed in the correct position and drilling perpendicular.

The diameter of the hole for the dowel must correspond to the size of the fastener. You should pay attention to the moment that the element of the fastening system enters the hole with some force. It is important that the length of the dowel must be equal to the length of the screw.

When installing in a concrete base, it is necessary to use a drill whose diameter is equal to the diameter of the fastener. If the supporting structure is made of brick, then in this case you can make a hole 1 mm smaller than the dowel. To control the depth, you should put a mark on the drill itself, which will serve as a kind of boundary for the planned hole. It is placed at a drill depth slightly exceeding the length of the dowel. You can put electrical tape on the drilling tool as a mark.

The hole for the dowel is made with a drill with a Pobedit tip if the work is carried out in concrete or brick. It is installed perpendicular to the surface. To clean the hole from cement residues and other debris, it is most effective to use a vacuum cleaner or blow-out pump.

In order for the fastening to be reliable, you need to know how to drive the dowel correctly. To do this, you need to insert it into the hole and press the fastening device with light blows of a hammer. Then you can screw a screw into it and use it to fasten the necessary elements.

How to choose the right drill bit for a dowel?

The correct selection of a drill for a dowel directly depends on the type of working surface. So, for example, if the fastener is supposed to be made in a brick or reinforced concrete surface, and the attached element itself has a small mass, then you should opt for a drill whose thickness is 6 mm. In this case, the diameters of the dowel and the drill with a Pobedit tip must match.

In addition, you also need to know that the dowel must go to a depth of at least 40 mm if installation is carried out on the wall. In the case when it is performed on the ceiling, the minimum depth must be at least 60 mm. This is affected by the load on the dowel, which in the latter case will be greater.

When working with similar surfaces for fastening medium-weight devices or elements (whose weight is from 5000 g to 10000 g), you should choose dowels and a drill with a diameter of 8 mm. The depth of insertion of the fastener into the wall must be at least 60 mm, and into the ceiling surface 8 cm. These are the dimensions of the dowel and drill that must be observed for reliable installation.

When fastening in old buildings, it is recommended to use fasteners with a diameter of 1 cm or 1.2 cm, and the insertion depth should be at least 6 cm. To work with such fasteners, you should choose drills whose diameter is 2 mm less than the dowel itself.

How to remove a dowel

During the renovation of apartments and the reconstruction of entire buildings, there is often a need to learn how to remove a dowel. The method for disposing of an old fastener depends on the material from which it is made.

If the dowel is made of plastic, then to remove it, in many cases it will be enough to screw in a self-tapping screw and pull the entire structure out of the hole using pliers. You can also use a nail puller for this. It will definitely come in handy if bearing capacity dowels are very high. The long lever allows you to apply more effort to the fastening system.

If a person does not know how to remove a dowel from a wall in which part of the screw is stuck, then it is recommended to try using a soldering iron. With its help, you will need to try to melt the fastener body, made of plastic.

If the dowel is made of metal, then the fastener can be pulled out after blows are applied to the protruding part to loosen it. When this cannot be done, he uses a drill with a special drill. With their help, indentations are made around the nest. After this, dismantling will be much easier.

Read also...

- Version: The true teaching of Christ is based on the Vedic tradition

- Ancient faith of the Slavs Slavic faith before Christianity

- "Plane under the bridge": anniversary of Siberian aviation hooliganism

- Atrocities of fascism: murders of children, fascist child killers - history in photographs - LiveJournal Russians killed the children of fascists