How to waterproof a basement from the outside. Engineering analysis of types and methods of waterproofing underground parts of a building from groundwater. Pasted waterproofing of basement walls

The problem of high humidity and condensation in basements is relevant for many country homeowners. Very often it occurs due to incorrectly made or ineffective waterproofing (both external and internal). The reason may also be the wrong choice of insulating material, when the emphasis is on its versatility, without taking into account the specifics of operation. Waterproofing basement walls should be done during the construction phase of the house. And it is best to do it from the outside, because the effectiveness of insulation made from the inside is much lower.

In cases where country house was built a long time ago, and the problem of dampness in the basement arises constantly, it is necessary to think about updating the moisture-proof layer. It should be noted here that installing external waterproofing in already built houses is fraught with many difficulties. After all, you will have to re-dig the pit under the walls, which may negatively affect the performance characteristics of the foundation. Therefore, you can choose from two options here: either entrust the work to professionals, or start installing an internal waterproofing layer in the basement.

There are several methods for waterproofing basement walls, which are the most widespread.

Coating waterproofing

Coated insulation is best suited for you if the problem of capillary moisture penetrating into the basement is a pressing issue for you. Waterproofers of this type are presented in the form of mastics, which must be applied to the walls using a spatula and other tools. As soon as the insulator dries after application, a monolithic film will be formed on the surface, which will provide protection from moisture for a long time.

Coating waterproofing is performed using special mastics.

For many years, bituminous mastics have been the market leader in coating waterproofing materials. Without a doubt, they are effective. But their main drawback is their limited service life. The service life of a bitumen-based insulator does not exceed several years.

The modern market offers a solid range of hydrophobic materials that fall into the category of coating waterproofing. Most of them are made on the basis of polymers and minerals. Their composition, as a rule, includes special modifiers, which make it possible to provide all the necessary properties of the material.

The main advantages of modern coating waterproofing:

- Ease of use, ease of application to the wall surface, elasticity of the composition.

- Goes well with concrete walls and any other surfaces made from mineral materials.

- Durable, reliable and effective insulator.

- Reasonable prices for compositions designed for use in basements and cellars.

Pasted waterproofing

Pasted vertical and horizontal waterproofing has been used for a long time and everywhere. It involves the use of waterproof roll materials that can be glued to the basement wall from the outside and inside. Installation occurs using special adhesives or by fusing. It is very important to be careful when working with waterproofing adhesive materials, because there is a high probability of mechanical damage due to careless installation.

Today, as experts note, everything fewer people They use traditional adhesive insulators such as roofing felt and roofing felt, because these materials are not able to provide a sufficient level of protection from moisture, and also cannot boast of a long service life. On the market you can now find durable, reliable and effective adhesive waterproofing insulators, which are produced using European equipment and international technologies from synthetic substances such as fiberglass and polymers.

Before gluing, the rolled material is heated.

Self-adhesive insulation in rolls can also be found on sale. Of course, working with such material is very easy and you can handle everything yourself, however, its use as the main waterproofing layer is not recommended. If you have a small basement where the problem of high humidity and dampness is not too pressing, then self-adhesive waterproofing will be an excellent solution for you.

Experts recommend paying special attention to modern membrane waterproofing materials, which are produced on the basis of polymers and bitumen. IN recent years More and more country homeowners are choosing membrane materials that provide a high level of protection from moisture. In addition, they are durable and resistant to mechanical damage. Membrane waterproofers are quite expensive, but their performance characteristics and service life are beyond doubt.

The use of penetrating waterproofing is one of the most effective ways providing moisture protection for basement walls made of brick or concrete. Insulation of this type is presented in the form of dry cement-sand mixtures, which have been modified with the help of chemical additives.

The active substance of the insulator penetrates into the structure of the wall material, completely filling all microcracks and openings. As a result, all capillaries through which moisture could potentially enter the basement are completely clogged, and the water permeability of the walls is reduced to almost zero. In many ways, the effectiveness of this type of insulation will depend on the correct preparation and application of the solution.

The composition penetrates the pores of the material and clogs them.

To prepare a solution of penetrating insulation, you need to fill the purchased mixture with water in the proportions specified in the instructions. Too much or insufficient amount of water will reduce the activity of the active substances of the insulator, as well as worsen their further interaction with the wall material. Before applying the solution to the wall, you need to clean the surface from dirt, grease stains and old finishes. This approach will open up many pores and also increase the absorbing properties of the material.

Penetrating waterproofing also has its disadvantages. This insulator is not elastic, may crack during use, and does not guarantee durability of use under constant exposure to water from the outside and inside.

Injection waterproofing

Injection waterproofing is one of the most suitable and optimal methods for getting rid of moisture. With its help, you can eliminate leaks in the walls of the basement or cellar. The principle of operation of this insulation is that it fills all visible cracks.

This type of insulation is applied using special equipment, therefore, in this case it is impossible to do without the involvement of specialists. It should be noted that the base of the insulator is polymer resins, which are completely safe for indoor use. This is a great option if you need high-quality waterproofing from the inside.

Injection is an ideal way to get rid of leaks.

Among the main advantages of injection isolation are:

- Complete elimination of existing leaks from cracks. The entry of moisture into the basement is blocked immediately after the insulation is applied.

- There is no additional need to prepare the wall surface, because cracks are filled from the inside and only in those places where it is necessary.

- The insulator does not require any special care.

- The material is elastic, durable and reliable.

This is an ideal solution for fixing leaks from inside the basement. Especially if you are not concerned about groundwater.

Choosing an insulation method

If you need waterproofing of walls from the outside or inside, then you can choose one of several options for its installation proposed above. Of course, many experts recommend using combined options when, for example, coating and roll insulation are used on the same wall. This approach allows you to reliably protect the basement from moisture penetration, as well as from the formation of condensation.

The choice of one or another method of installing a waterproofing layer will depend on the characteristics of the premises and the specific use. For example, somewhere the walls outside are affected by groundwater, somewhere by high water, and somewhere just by precipitation. For different cases, comprehensive vertical and horizontal insulation of basement walls is arranged.

The construction of a foundation without prior protection from precipitation and groundwater is fraught with the penetration of moisture through the structure of concrete, which has pores in the surface of walls and basement floors. The appearance of dampness in basement-type rooms is a prerequisite for higher level moisture in it, the appearance of fungus and an unpleasant odor. In addition, the presence of any surfaces without insulation is a potential place for loss of a limited amount of heat in the room. Finally, cracks that form when exposed to moisture can reduce the strength of the structure and reduce the service life of the structure.

Where does dampness come from in basements?

The appearance of dampness on the walls of basement-type premises, which contributes to the appearance of fungal formations, which in turn are a source of unpleasant odor, is associated with poor-quality waterproofing or its absence.

Other consequences that arise from non-compliance with SNiP standards are leakage in the area of the seams or at the junction of foundation elements. Among the factors influencing the appearance of dampness are the following:

- Lack of tightness at the joints of the material used for waterproofing. The defect appears as a result of improper installation or changes in the internal properties of the material under the influence of groundwater or precipitation.

- Performing a blind area in violation of technology, causing damage or destruction. In case of precipitation penetration from the outside of the building, waterproofing should be done in these places. Carrying out this operation involves eliminating the poor-quality blind area and building a new one.

- Systematic formation of condensate associated with temperature changes in the external environment. This occurs when the basement structure is improperly designed, in which warm air tending to rise upward interacts with the cold surface of the walls.

Measures to prevent dampness

Preventive measures to prevent high humidity in basements include:

- elimination of damaged foundation layers;

- processing of cleaned surfaces with a metal brush or using fixed brushes or abrasive on the surface of the hammer drill;

- digging canals;

- drainage for the purpose of draining water;

- laying horizontal and vertical waterproofing;

- construction of a blind area.

Requirements for waterproofing and blind area

To eliminate the destructive influence of water on the surface of the foundation and walls, a number of conditions must be met to ensure protection against the penetration of any types of moisture. Among the main requirements for waterproofing:

- ensuring the presence of a protective coating around the perimeter of the entire fenced area;

- applying a protective layer against the threat of groundwater penetration during the spring flood and the action of hydrostatic pressure;

- correct selection of a waterproofing scheme, taking into account seasonal fluctuations in groundwater levels, the type of existing groundwater, and the coefficient of water permeability;

- selection of protective material in accordance with individual conditions at the site of foundation construction;

- applying a protective layer to the level of the base in order to prevent the impact of snow on the foundation and walls during large amounts of precipitation;

- When the groundwater level is close to the surface of the earth, there is a high risk of creating an overly moistened area; to avoid this, a drainage system for water removal is installed.

Performing a blind area

The construction of any type of foundation must include several types of protection from the effects of groundwater and precipitation. To protect the foundation and walls of the structure from the effects of rain, melted snow and other types of precipitation, a blind area is made along the entire perimeter of the building. The blind area is a strip of asphalt, stone, tiles or concrete of varying widths and thicknesses, at an angle of up to 10°. The width of the blind area, as a rule, is in the range of 60-120 cm, the thickness is selected based on the conditions of the site and the material used. It is performed in the direction from the foundation and walls of the building in order to drain precipitation. The requirements for the material for the blind area are the absence of mechanical damage and moisture transmission. This type of coating is performed for any type of construction and for correct execution copes well with protecting the building from moisture penetration.

Waterproofing against groundwater

The situation is more complicated with waterproofing equipment to prevent exposure to groundwater. One of the main factors, depending on which a certain type of waterproofing device is chosen, is the groundwater level at the construction site. Even with deep groundwater, during a seasonal rise in its level, there is a danger that it will reach the level of the foundation and walls of the structure. In some cases, for example, when building a house on water-resistant soils, water moves in the direction of least soil resistance, that is, in the direction of the foundation. Water-resistant soils include sandy loam, loamy and clayey types.

Types of groundwater

When choosing the type of waterproofing, it is important to take into account the specifics of the foundation and the pressure characteristics of groundwater. In general, according to the last feature, 4 types of groundwater are distinguished:

- groundwater in a free-flowing state;

- sources of moisture with low pressure;

- pressure type of groundwater is characterized by the possibility of independent release to the surface;

- sources of moisture in a closed volume, also classified as suspended.

Waterproofing the foundation and basement: types and technology

Types of waterproofing of foundations and basements

To fully protect against moisture, it is necessary to perform waterproofing in two planes:

- Vertical insulation is performed to protect against the influence of groundwater from the basement walls. This can happen when the groundwater level rises or if a structure is built on water-resistant soils. There are two options for protection against moisture: using bitumen in rolls, glued to the surface of the wall, or by applying several layers of bitumen in a liquid state to them.

- The horizontal type of moisture insulation is used if the base of the basement coincides with the location of groundwater in height or if there is clay soil high density. The horizontal type of moisture insulation is carried out in the form of a protective layer applied along the perimeter of the plane according to one of three options, depending on the location and pressure characteristics of groundwater.

In the first case of groundwater location below the level of the base of a structure without a basement, for protection it is enough to apply a 2-3cm layer of cement-sand mixture at a height of 15-30cm from the base over the entire area of the foundation.

In the case of low groundwater levels and the presence of a basement in the house, a protective coating is provided on the outside and during the construction of the foundation. Possible combinations include combining protection along the edge of the foundation structure, covering the walls with molten bitumen and performing protection at floor level.

When groundwater occurs close to the surface of the soil for foundations and walls of a room, waterproofing involves performing several types of protection. Among them: uniform application of a 20-30cm layer of cement-sand mixture, laying of protective material in several layers, vertical type protection carried out by applying several layers of bitumen placed on mastic.

Waterproofing of foundations and walls for different levels of groundwater provides for protection according to one of the following schemes:

- When installing waterproofing in an area with groundwater located at a depth of up to a meter from the foundation level, taking into account the rise of capillary-type water, it is recommended to carry out coating protection.

- When groundwater is located at a greater depth, some experts recommend abandoning waterproofing, however, taking into account the possible impact of site development on groundwater, it is better to carry out protection using coating-type insulation.

- In the case of a high location of groundwater, the level reaching the lower part of the base of the building, it is recommended to jointly perform waterproofing with the installation of a drainage system.

Waterproofing technology

For strip foundation

Before waterproofing, it is necessary to ensure that the surface of the foundation is as flat as possible. It is necessary to apply molten mastic with bitumen to the surface of the base, placing them in an even layer. On top there is a roofing material covering with an overlap of up to 20 cm. It is possible, after leveling and drying the surface, to apply protection in the form of a spray coating on which a reinforced coating is applied. Another option for a protective coating is to apply a cement-sand mortar.

For pile foundation

For the manufacture of structural elements, it is assumed that moisture-resistant grades of concrete will be used. Considering the difficulty of performing waterproofing at the location of the support structures pile foundation, it is performed at the level of the grillage.

Insulation of walls and floor surfaces from the inside of the room is carried out to protect the joints of elements. If there are large gaps left at the joints, they are sealed by packing them with a layer of clay. The thickness of the places where the base elements are connected must be at least 2 cm. After sealing the seams, mastic is applied to the surface of the walls, followed by fastening the reinforcement and sealing the area with a layer of plaster.

Typical foundation waterproofing schemes

Application of coating protection

Coating protection is represented by liquid compositions based on bitumen mastic using various additives. When painting the foundation and basement walls from moisture, a layer of a special mixture is applied to the prepared surfaces, which has hydrophobic characteristics after drying. The most common practice is to make several thin layers of a protective composition, on which a layer of clay is applied. The thickness of the clay coating is up to 5cm. The areas between the blocks or bricks are filled with mastic, after which the wall is treated with a spatula until flatness is achieved.

Application of penetrating waterproofing

This type of protective coating is characterized by penetration into the structure of the material, due to which a monolithic composition without gaps is formed, which has hydrophobic characteristics. An additional advantage of this type of protective coating is that the resulting structure is resistant to temperature fluctuations. In this case, there is no possibility of condensation forming, since this type of protection has the ability to allow steam to pass through. Molten glass is used as a material for penetrating waterproofing. After cleaning the wall surface from the previous coating and brushing it with a metal brush, the composition is prepared. It is done by adding powder to water while stirring the mixture. The mixture is applied starting from the corners, after preliminary moistening the surface. Several more can be applied to the first layer with a break between approaches of up to 3 hours necessary for the previous layer of the mixture to dry.

Waterproofing using cement-sand mortar

It is common practice to use a hydrophobic type of cement or Portland cement to perform a protective coating. This type of coating is highly reliable and has the best characteristics, while at the same time having the greatest labor costs. After cleaning the surface of the walls and wetting them with water, the solution is prepared. The mixture should have a thick and at the same time plastic consistency and should not contain large fractions. The consistency will depend on the planned thickness of the applied coating. The composition is evenly distributed over the plane of the foundation and walls.

Pasted waterproofing

It is one of the types of protective coatings most used in practice, made using waterproofing agent or roofing felt. These materials are glued to mastic previously applied to the surface of the walls, or fixed by melting the composition gas burner. The required number of layers of roofing material will depend on the pressure characteristics of groundwater. After cleaning the surface of the foundation and walls from dirt and leveling, it is necessary to coat their surface with a primer that has good adhesive properties. The material for gluing is prepared by cutting strips of roofing felt from rolls. Their length is equal to the height of the basement with the addition of 15 cm of allowance for fixation on the floor surface. The surface of the walls is covered with mastic, after which the resulting strips of insulation material are attached to it with an overlap of 10-15 cm and the joints are treated with TechnoNIKOL.

The specific operation of basements requires special attention to the level of humidity. If you ignore this aspect, problems associated with groundwater leaks, accumulation of dampness and mold will inevitably arise. For the building itself, this threatens subsidence of floors and walls, cracking of foundation slabs and, as a result, the building being assigned the status of “emergency.” This picture is typical of many old buildings, during the construction of which internal waterproofing was not provided. The sooner you pay attention to proper protection of the interior from moisture and complete waterproofing in the basement, the less consequences there will be for the structure and the more acceptable the cost of repairs. To solve this issue comprehensively, it is better to order basement waterproofing work from professionals.

Cost of basement waterproofing work (per m2)

Basements are the most vulnerable, because their structure is exposed to groundwater and precipitation from outside, and lack of ventilation and natural light worsen the situation inside. Most often, the cost of waterproofing basement walls consists of the cost of materials, depreciation of the equipment used, labor and time components, and the complexity of the work. To roughly calculate how much basement waterproofing will cost, you need to know the surface area that needs treatment, as well as the main basic indicator - the price per m2.

Another relevant service is the repair of internal and external basement waterproofing, the price of which depends on the degree of damage and the number of components. In general, modern waterproofing of residential and non-residential premises, including basement walls, should be planned during the construction of the building, then the price will be adequate.

When making a decision, the cost of waterproofing the basement plays an important role. You can find out the exact price of this service after drawing up an estimate.

Cost of work*

*The services and their costs shown in the table are basic. To calculate the estimate and choose the best option, call the Moscow office of our company.

Types of basement waterproofing

When choosing a service such as basement waterproofing, you need to decide on the type necessary work. This can be vertical or horizontal treatment, the choice of which depends on the groundwater level. If there is no drainage system around the building where the basement is located, and the walls are at the same level with underground moisture, it is necessary to carry out vertical waterproofing. For those houses in which groundwater does not exceed the level of the basement floor, horizontal is suitable.

There is also a division of waterproofing into three groups depending on the intensity of exposure to a humid environment:

Anti-pressure – carried out outside the building, protecting structures from floods and seasonal increases in moisture levels in the soil. The concrete surface is treated with liquid rubber and covered with a special membrane or roll seals. Due to moisture pressure, the material adheres more tightly to the surface, providing reliable protection against leaks.

Non-pressure - installed at sites where the basement is not exposed to water from the ground. By treating surfaces with bitumen or polymer mastic, walls are protected from aggressive environments. For a lasting and long-lasting effect, it is necessary to plaster the surface over the insulation with a cement layer at least 0.5 cm thick.

Anti-capillary - a reliable layer of waterproofing made from materials based on epoxy, acrylic or polyurethane prevents the penetration of moisture that rises through the capillaries of the concrete mass.

Waterproofing materials

Manufacturers offer various options materials for waterproofing the basement from the inside or outside. It is important to choose composites from trusted manufacturers and take care of the most favorable delivery.

Among penetrating compositions, the use of cement mixtures with the addition of quartz sand and water-repellent chemical components is justified. Polymer and bitumen mastics, which form a waterproof, durable layer, are popular for coating waterproofing.

Pasting waterproofing is done using rolled materials, such as classic roofing felt or more modern analogues - hydroisol and glass insulation.

Sometimes water repellents are used to waterproof a basement. The components of such compositions do not penetrate deeply, so they are used as additional measures. Regardless of what materials are chosen, the work on waterproofing the basement should be as effective as possible, and the price should be reasonable.

Basement waterproofing consists of the following steps:

- Preparatory work, including cleaning of concrete surfaces. These measures cannot be ignored, because they allow access to the capillaries, which is necessary for the quality implementation of subsequent actions;

- Opening cracks and crevices;

- Applying a primer layer. The composition is applied with a roller or brush to a moistened surface;

- After drying, a waterproofing material is applied depending on the chosen method.

What we offer

The InzStroyIzolyatsiya company specializes in a wide range of services related to protection against the destructive effects of moisture. A team of builders will carry out comprehensive turnkey waterproofing of the basement in Moscow. We are not afraid of large-scale projects and complex tasks, we know how to find optimal solutions and guarantee quality. Our company’s specialists will help protect the basement from groundwater penetration, ensuring a reliable effect. The best quality materials and modern equipment are used.

Order basement waterproofing

At any time of the year, you can order basement waterproofing in Moscow from the InzhStroyIzolyatsiya company. We will ensure that your building is protected from destruction and other problems associated with dampness. We guarantee an individual approach, competent budgeting and high-quality results. To receive advice or services on basement waterproofing, just call or leave a request on our website.

Need to waterproof your basement? Call InzhStroyIzolyatsiya LLC right now!

Using the example of specific compositions from a specific manufacturer, we will consider waterproofing the basement from groundwater. This information can be considered as the use of Maxrite 500 and Maxsil Super compositions. All work can be done with your own hands.

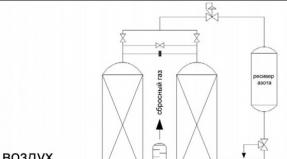

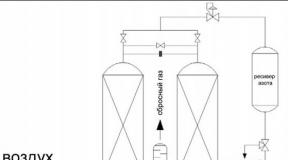

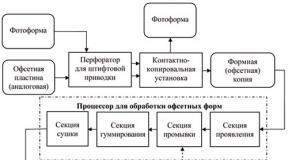

To protect the basement and light pits from water, the following is provided:

· use of concrete for the foundation slab and basement walls, grade W6 for water resistance;

· use of waterproofing coating “Maxsil Super” with penetrating action;

· insulation of concreting joints with the “Inzhpipe” system;

· insulation of the foundation slab-wall joint with the expanding composition “Maxright 500”.

· installation of vertical concreting joints in external walls to prevent the formation of shrinkage cracks by placing the Inzhpipe system in these joints.

"Maxsil Super" is applied to the concrete preparation of the foundation slab (pit slab) and the outer surfaces of the basement walls (pit walls).

Scheme of waterproofing foundation slabs and basement walls.

At the junction of the outer walls of the basement with the foundation slab, cut a groove 20 mm deep and 20 mm wide (without damaging the reinforcement) in the seam and fill it with the expanding composition “Maxright 500”.

The waterproofing applied to Maxright 500 from Maxsil Super is additionally reinforced by the elastic waterproof coating Maxsil Flex.

Protection of the Maxsil Super coating from damage during execution backfill provided with polyethylene fabric “Maxdrain-P8” with protrusions facing outwards. To prevent the canvas from sliding when backfilling, it is necessary to fasten it in the upper part (above ground level) to the walls with dowels.

Technological openings in the walls from formwork ties are freed from conical polyethylene couplings. The resulting conical holes from the outside are drilled with a diameter of no more than 50 mm to a depth of 20 mm to obtain a cylindrical recess, which is then filled with the expanding composition “Maxright 500” and coated with “Maxsil Super”.

To protect the basement from water penetration through utility openings, gap filling is provided. mineral wool or an stuffing box gasket (see waterproofing unit for communications input), closed on the outer and inner surfaces with a layer of Maxjoint Elastic composition. The outer surface is coated with “Maxsil Super” and the waterproofing is additionally enhanced with a layer of “Maxsil Flex”.

At the bottom level of the ceiling, horizontal seam waterproofing is provided with a Maxsil Super coating.

The installation of waterproofing is carried out in full accordance with the technological regulations of the manufacturer, “Guidelines for the use of materials DRIZORO S.A. (DRIZORO S.A.) for waterproofing building structures (RD 01-09)”, a work project that guarantees the quality and durability of waterproofing.

Waterproofing protects the basement from the harmful effects of ground and surface water. Even the strongest concrete has pores and microcracks throughout its entire volume, which have little effect on strength, but can allow water to flow into the structure. Over time, water reduces the characteristics of concrete, contributes to the destruction of reinforcement, and increases heat loss in the house. This is critical for a basement where humidity increases and there is a risk of flooding during spring floods or heavy precipitation. Effective protection is waterproofing the basement from the outside from groundwater; it is only important to choose the optimal waterproofing option.

A set of measures for waterproofing the basement and foundation

Moisture protection for the foundation and basement is always a set of measures aimed not only at creating a durable barrier, but also at draining ground and surface water away from the house, garage or other building that has a basement. The structure of water protection systems is as follows:

- for drainage of groundwater;

- and blind area for drainage of surface water;

- waterproofing the foundation from the outside;

Let's take a closer look at the methods and materials used for waterproofing the basement from the outside. Based on the principle of application and purpose, there are three types of waterproofing:

- penetrating;

- low-pressure;

- high-pressure

Penetrating waterproofing is designed to protect and strengthen the concrete of the foundation. This is a whole group of compositions with similar properties and effects. Their main strength is the ability to penetrate deep into the concrete structure through microcracks and pores and clog them. This happens due to the polymerization of the elements of the composition, after which any, even the smallest capillaries in the volume of concrete are closed with polymer crystals. They are hydrophobic in nature and do not allow water to penetrate further, but have little effect on the vapor permeability of the material.

Low-pressure waterproofing provides immediate protection against moisture. This is a layer of hydrophobic insulating material fixed over the concrete base of the basement walls. These could be:

- roll materials from polymer films;

- bitumen-based roll materials;

- coating polymer materials;

- liquid rubber, bitumen-containing mastics and coatings;

- liquid glass.

Basic requirements for low-pressure waterproofing:

- uniformity and continuity of waterproofing properties of the finished coating;

- good adhesion to the surface of the foundation and basement walls;

- corrosion resistance and durability.

High-pressure waterproofing in itself is already a comprehensive solution. This is a durable and wear-resistant multi-layer structure, the main purpose of which is to withstand high groundwater pressure. A mandatory type of protection for houses and other structures with deep foundations and basements, near which groundwater rises above the edge of the structure.

The protection consists of several layers of waterproofing material alternating with cement plaster. Polymer or bitumen-containing fillers are added to the plaster solution, which can give it hydrophobic and waterproofing properties. For rigidity and strength, pressure waterproofing is additionally reinforced with galvanized steel or polymer mesh.

It is worth remembering that even the most reliable and thick-walled waterproofing will last a long time and without problems only if there is an effective drainage system organized around the perimeter of the building and a strong, wide blind area with a clay lock.

Complete basement waterproofing includes protection of walls and floors. The best option protection will be erected during the construction stage of the building. If you need to restore or replace protection on an already used house, you will have to expose the foundation and, if possible, replace the floor in the basement or form a second layer with a new layer of waterproofing.

Materials

For external waterproofing, materials must be strong, durable and resistant to impact. aggressive environments. Specific materials such as polyurea or sprayed polyurethane are no longer advisable to use. By itself, bitumen mastic is not suitable as an independent product and is combined with other materials that can take on part of the load.

Penetrating waterproofing

An extensive section of waterproofing compounds, the main task of which is to impregnate concrete and plug pores and microcracks, preventing the penetration and spread of moisture. However, they should not, if possible, interfere with the vapor permeability of the material.

![]()

This is a mandatory element of external basement waterproofing. It is advisable to use penetrating compounds at the stage of pouring concrete into the foundation and basement walls, when the solution has already been poured, but has not yet dried. To treat structures that are already in use, deep penetration primers and diluted penetrating waterproofing are used.

Ruberoid

Classic bitumen-containing waterproofing material. Ruberoid is glued on top of basement walls and building foundations. To do this, strips of material and the base of the walls are heated with a gas burner and pressed tightly against each other. Forms a fairly tight contact.

The base is fabric made of polymer fibers or thick paper. The first option is preferable, because polypropylene and polyester fibers do not rot and give the material tensile strength, which is especially important, because the waterproofing layer will come into contact through the geotextile with the soil and backfill of the drainage system.

![]()

Polymer membranes

Film and roll materials made of polypropylene or PVC with a reinforced structure. Over the entire surface, protrusions are formed by pressing in the shape of a truncated cone and microperforations, if it is a vapor-permeable membrane.

Polymer membranes do not provide tight contact with the base. More often, polymer waterproofing is held in place by pressing with a layer of soil or additional lathing, boards, etc.

Liquid rubber

![]() Liquid rubber is based on the same bitumen with the addition various polymers, rubber and binding components. Initially, the composition is diluted with water and applied to the surface to be treated. After setting and polymerization, a seamless waterproofing coating 3-10 mm thick is formed with high adhesion to concrete. Since the strength of the layer is quite weak, reinforcement with polypropylene mesh or galvanized steel mesh is used. High-pressure waterproofing consists of alternating layers of liquid rubber with cement plaster and reinforcement.

Liquid rubber is based on the same bitumen with the addition various polymers, rubber and binding components. Initially, the composition is diluted with water and applied to the surface to be treated. After setting and polymerization, a seamless waterproofing coating 3-10 mm thick is formed with high adhesion to concrete. Since the strength of the layer is quite weak, reinforcement with polypropylene mesh or galvanized steel mesh is used. High-pressure waterproofing consists of alternating layers of liquid rubber with cement plaster and reinforcement.

Liquid glass

Liquid glass in its pure form is not used in external waterproofing of basements. It is added to cement mortar for plastering, used as an additive to coating compositions or as an impregnation for pre-treatment of joints, cracks and other damage during restoration work.

Bitumen mastics

It is used on the same principle as liquid rubber, and also as an additive to other coating compositions. By itself, bitumen does not have sufficient strength and durability to cope with loads.

Cement waterproofing

Complete external protection of basement walls is not possible without a layer of plaster, which will protect the waterproofing materials and provide strength to the entire set of measures to contain groundwater. Cement compositions with the addition of bitumen, liquid glass or polymer components are used to perform restoration work.

Injection waterproofing

A separate type of external waterproofing. To protect an already in use building, when it is not possible to expose the entire depth of the foundation, much less reach under the base of the floor in the basement, waterproofing materials can be delivered to the outside using the injection method.

![]()

On the inside of the walls and floor in the basement, through holes are drilled according to a certain pattern or following a certain step. Next, using special nozzles and a compression unit, the waterproofing compound is pumped through the holes. Hardening on the outside of the foundation, the solution forms a durable layer of high-pressure waterproofing.

Wall waterproofing technology

Procedure for restoring waterproofing of the foundation and basement walls from the outside:

- The blind area is dismantled and soil is selected to create a trench at least a meter wide around the perimeter of the basement. If necessary, groundwater should be pumped out during work. The old finishing and waterproofing are completely dismantled. Further work is carried out after the concrete surface has dried, this may take several days or the use of heat guns.

- The bare part of the concrete base from the very base and up to the base 10-20 cm above the ground level is precisely the target surface for organizing a waterproofing layer. It must be cleaned of soil and other contaminants. It is best to use an angle grinder with a medium-hard brush to open pores and cracks and eliminate all defective areas.

- The seams between blocks or individual elements of the foundation are selected to a depth of at least 5-6 cm. In the case of a tight joint between the blocks, the seams are expanded so as to obtain a groove 2-3 cm wide and 3-4 cm deep. Cracks are grooved, and other damage is further deepened, It is advisable to deepen and widen pinpoint damage using a 40-60 mm drill.

- The entire surface is cleaned of dust and dirt and covered with penetrating waterproofing or primer.

- The previously prepared grooves and recesses are filled with cement waterproofing mortar with the addition of liquid glass or polymer components. It is advisable to use ready-made coating mixtures for waterproofing. Further work is carried out after the solution has dried and the foundation surface is leveled.

- For complete high-pressure waterproofing, first the basement walls from the outside are plastered with a cement waterproofing compound with reinforcement.

- A layer of waterproofing is applied (roofing felt, polymer membranes, bitumen-containing mastics or other coating agents intended for waterproofing foundations).

- The second time the surface is plastered.

- Sand is poured into the bottom of the trench and compacted. A layer of geotextile is fixed to the bottom of the trench and its reverse side. Coarse gravel is poured and a drainage pipe is laid with an outlet into a prepared well for drainage. The gravel backfill layer is increased by another 10-15 cm on top of the pipe and covered with geotextiles.

- The soil is filled in, leaving a depression to form a blind area. A layer of clay is laid for the clay castle. The reinforcement is laid, the blind area is cast.

When constructing a new foundation and basement, impregnating waterproofing materials are used while the concrete is not yet completely dry. Naturally, restoring the integrity of the concrete base is also not required.

Floor waterproofing is carried out on top sand cushion. Roofing felt is laid and a rough screed is poured on top of it; liquid glass or appropriate plasticizers and hydrophobic additives should be added to the concrete.

Read also...

- Version: The true teaching of Christ is based on the Vedic tradition

- Ancient faith of the Slavs Slavic faith before Christianity

- "Plane under the bridge": anniversary of Siberian aviation hooliganism

- Atrocities of fascism: murders of children, fascist child killers - history in photographs - LiveJournal Russians killed the children of fascists