Types of gas burners for heating boilers. Gas burner automation: how it works, types Comparison of the efficiency of gas burners of different types

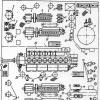

Gas burner GGU-40 (power 36 kW) with automatic control and safety Honeywell VK4105G

Automation provides automatic ignition of the burner, maintaining the set temperature in the room up to +120 С

Gas consumption: - 4 m3 / h (network gas), - 3.3 kg / h (LPG).

General instructions

This operation manual (OM) describes the model of the gas-burner device "Spectrum" GGU-40.

The OM contains information on the design, product parameters, device and operation, as well as rules for safe operation, maintenance and storage of the product, possible malfunctions.

Before starting work, carefully read this Operation Manual. The manufacturer does not accept claims in case of violation of the rules of preparation for work, operation and maintenance of the product.

Due to constant work to improve the product, increasing its reliability and improving quality, design changes may be made that are not reflected in this manual.

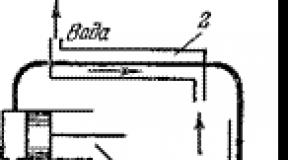

In the normal position, the main gas valve (1) is closed by the spring (2) and can only be opened when the gas pressure becomes sufficient to resist the spring force. This very important built-in reliable mechanism ensures that the valve closes automatically in the event of a gas or power failure.

The main part of the system is a servo-actuator consisting of a pressure relief valve (5) built into the regulator diaphragm, which is installed on top and controls the operation of the main valve.

When the safety valve coil and the auxiliary valve coil are energized, gas flows through the port and open valve (5) to the servo system and regulator

This gas presses on the diaphragm (6) of the main valve, forcing it to rise and open the main valve. As soon as the main valve opens, the outlet pressure generated by the regulator is sensed by the diaphragm through the feedback channel.

As soon as the pressure force exceeds the value, the preset regulator valve will open, resulting in a decrease in the working pressure. This will also decrease the force acting on the main valve spring, which will lead to proportional closing of the main valve. Thus, the valve allows the outlet pressure (burner pressure) to be kept at a preset level.

In this way, the outlet pressure is constantly maintained at a certain level by comparing its value with a preset value and corresponding valve adjustment. It means that constant value outlet pressure is maintained regardless of fluctuations in inlet pressure.

When the valve is turned off, a small amount of working gas contained in the regulator and diaphragm chamber above the main valve is discharged into the main outlet compartment.

The reference pressure feedback system further stabilizes the outlet pressure by compensating for the difference in air pressure between the valve and the chamber.

If no pressure adjustment is required, the regulator spring can be locked by turning the adjusting screw all the way or until the pressure regulator is disengaged. In this case, the full working gas pressure opens the main valve as much as the pressure drop allows.

Intended use

2.1. Operating restrictions

2.1.1. The gas burner device can be installed in hot water heating boilers of low power and in household stoves.

2.1.2. The room in which the gas burner device is operated must comply with the requirements of the Safety Rules for Gas Distribution and Gas Consumption Systems.

2.1.3. Work on the installation of a gas burner device must be carried out by employees of the gas service in accordance with the requirements of the "Safety Rules for Gas Distribution and Gas Consumption Systems".

2.1.4. After the installation of the gas burner device, the control and safety automatics must be checked for operation in all parameters and adjusted.

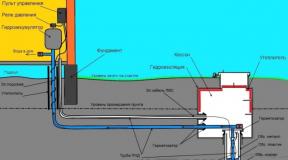

2.2 Installing the gas burner

The installation of the gas burner device must be carried out in the following sequence:

2.2.1. Fasten the GGU to the furnace wall with bolts, Figure-5, after placing a heat-resistant sealing element on the inner surface between the GGU and the furnace wall.

2.2.2. Install the draft sensor pos. 3

2.2.3. Connect the draft sensor to the valve controller

2.2.4 Install the thermal bulb at a height of 1.5 - 2 m by fixing it to the wall. If the gas turbine unit is installed in a sauna oven, the thermocylinder must be installed in the steam room, as far as possible from the oven.

ATTENTION: In the bathhouse, install the control unit in the dressing room.

Do not install a control unit in a sink or steam room.

2.3 Product use

ATTENTION: DURING IGNITING AND OPERATION OF THE GAS BURNER,

THE ASHIRE MUST BE OPEN.

BEFORE TURNING THE BURNER INTO OPERATION, IT IS NECESSARY:

... check the presence of draft in the chimney and the absence of a smell of gas in the room;

... ventilate the room in which the gas apparatus is installed and its combustion chamber for 5-10 minutes, while the gas taps in front of the burner must be closed;

To turn on the GGU, you must:

... open the ash pan;

... set the thermostat knob to position "0";

... turn on the power (220V);

... open the gas valve on the gas pipeline;

... smoothly turn the thermostat knob clockwise and set the required temperature, the burner lights up at full power.

... visually verify the launch of the GGU.

... to turn off, set the thermostat knob to position "0";

... close the gas valve on the pipeline

... after turning off the burner, to prevent the furnace from cooling down due to draft, it is recommended to close the ash pan

2.4 Setting the maximum gas value Valve adjustment. Fig. 6 Pa - gas pressure at the inlet to the valve, Pb - gas pressure at the outlet, Pmax - screw for adjusting the maximum gas value

Setting max. pressure (P.max):

... Connect the positive pressure point of the gauge to the gas valve pressure point (Pb).

... Remove the cap from the gas valve and use a screwdriver to set the required pressure (Pmax).

... Check that the dynamic pressure at the test nipple (Pa) is correct and screw the plug back on.

2.5 Possible malfunctions

Fault Possible cause Remedy

GGU does not start No contact in the electrical circuit

draft sensor Clean the contact connection with fine emery cloth.

The draft sensor is out of order Replace the draft sensor

There is no contact in the electric circuit of the thermostat Check the contacts, remove the cover of the electrical contact block, apply voltage to the coil directly, bypassing the thermostat.

ATTENTION!!!

SUPPLY VOLTAGE OF THE REGULATOR COIL 220V

Emergency lock

controller Reboot the controller by disabling

and power on the valve

Safety requirements

3.1. Only persons familiar with the device and operating rules of the gas burner device and trained in safe methods of working with gas are allowed to service.

3.2. In order to avoid accidents and failure of the gas burner device, DO NOT:

... turn on the burner for children and persons who have not been instructed in operation;

... operate a gas burner device with faulty control and safety automation;

... use fire to detect gas leaks (for these purposes, use a soapy emulsion);

... turn on the burner in the absence of draft in the chimney;

... when turning on the burner, bring your face closer to the viewing hole by less than 0.5 m;

... the owner to repair the burner, as well as make any changes to the design.

3.3. When the burner is not working, the GAS VALVES MUST BE CLOSED.

3.4. If you smell gas in the room, immediately turn off the gas to the burner, open windows and doors, call the emergency gas service by phone 04, remove people from the room. Before her arrival and until the gas leak is eliminated, do not carry out work related to fire and sparking (do not turn on electric lighting, do not use gas and electric appliances, do not light a fire, etc.).

3.5. In the event of a fire, immediately inform the fire department by phone: 01.

Maintenance

4.1. Supervision over the operation of the burner is the responsibility of the owner, who is obliged to keep it clean and in good working order.

4.2. Preventive maintenance and repairs are carried out by gas workers in accordance with the "Instructions for the maintenance of indoor gas equipment".

Transport and storage

5.1. The gas burner device should be stored in a horizontal position in one tier in a closed room, which guarantees protection from atmospheric precipitation and other harmful influences, in the container of the manufacturer.

5.2. The gas burner device can be transported by any type of transport, provided that it is protected from mechanical damage and direct ingress of moisture.

Gas heating of industrial and residential premises is controlled by automatic control. Today's technologies make it possible to conduct accurate regulation the desired temperature, while saving on fuel. This result was achieved due to the use of burners with the power adjustment option, which is provided by the automation of the gas burner.

A gas burner with automatic control for a boiler is an apparatus that mixes gas with air and burns this resulting composition in a combustion chamber.

How does the automatic temperature control system work?

The simplest system of automatic regulation of the set temperature using a gas burner works as follows: gas is supplied to the burner, which is ignited by the ignition function, and thus constant combustion occurs. In this case, the burner itself works at its full strength. When a certain temperature of the coolant or air in the room is reached, the automatic equipment of the gas burner extinguishes the fire.

To maintain the set temperature, the burner is constantly switched on and off.

Classification of gas burners by temperature control

With the modern development of technology, new, improved methods of automatic temperature control have been developed:

- Single-stage burners are the simplest devices, the operating principle of which was described above. These burners operate in the same mode.

- Two-stage burners are devices that can operate in two states (40% and 100% of the total power), switching between themselves automatically.

- Sliding two-stage burners - these also operate in two states (40% and 100%), but the switching between modes is smoother, which significantly saves the fuel itself and improves the quality of temperature maintenance.

- Modulated gas burners with automatic controls for the boiler are the most functional devices capable of operating in a wide power range (from 10 to 100%). They can maintain a temperature regime with a deviation of only 20C from the initial value. At the same time, the efficiency of fuel combustion increases, and the temperature loads on the parts of the heater decrease.

The most effective of all is the copper heat exchanger, as it has thin walls and good thermal conductivity. BUT it does not tolerate high temperature voltages, therefore, it has a short period of operation. In combination with the modulating automatic gas burner, its service life is extended.

Gas burners with the option to change the combustion level are expensive, but their efficiency quickly pays for all the costs:

- the temperature is kept in a small range;

- fuel savings up to 30%;

- the service life of the entire device increases.

So we recommend buying a gas burner with automation!

The main elements of the auto-control system

Apparatus included in the burner electrical circuit to start the automatic operation of the device:

- Relay max. and minimal. gas pressure - has a light structure, which affects its long service life. The principle of operation is that the gas pressure affects the membrane, and when it deviates from the set mode, the system is triggered, and the control valve performs the required work. Relay min. gas pressure protects against a decrease in gas pressure to a critical point, and the maximum pressure switch adjusts, preventing an increase in the permissible value.

- Relay for min and max pressure of the heating agent - protects the heating system from excessive decrease and increase in pressure of the heating device. Both options are dangerous and undesirable for the continued operation of the boiler, therefore, when a critical point (lower or upper) is reached, the boiler shuts down, that is, the gas supply stops.

- The combustion controller is a part that integrates the operation of the entire burner into an overall process. The operation of gas burners of heating boilers with automation is divided into several sections, which correspond to the required position of the fuel control valve and air damper. Having received a low temperature signal, the controller opens the appropriate mechanisms to increase the combustion force. The controller's operation is based on signals from different sensors (temperature, pressure).

- The thermostat is a signaling device for reaching temperature limit levels. On its signal, the combustion modes are changed.

- Boiler filling sensor - is required to protect the burner from starting, without the presence of heat carrier in the boiler.

The connection of the sensors depends largely on the boiler manufacturer. This data can be seen in the passport of the device, and the features of connecting the sensors are carefully described in additional instructions. In this case, the connection and adjustment of the automatic system must be controlled by a gas service employee. In his presence, commissioning is also carried out, with the indispensable drawing up of an act on the serviceability of the equipment for safe operation.

Types of auto control systems for gas boilers

There are control systems of different brands and purposes, but they all work according to the same principles. They differ only in the functionality of the system and dependence on the electrical network.

All varieties can be combined into three main groups of gas burner automation:

- Non-volatile types.

- Volatile wire systems.

- Volatile wireless.

The non-volatile boiler control structure is the most basic automation for a heater. Its principle of operation is based on the physical law of expansion when the material is heated. A similar effect of such a law can be observed on the example of a thermometer - mercury, when heated, expands and rises up a tube fixed on the scale. The reverse process can be seen during cooling.

Now imagine that the same structure stands inside the boiler and measures the temperature of the heated device, only instead of mercury, another material (metal) is used. It expands when heated and affects the mechanical gas shutoff lever. As soon as the burner cools down, the metal is compressed, acting on the lever, and the gas flow is resumed again.

The volatile boiler control system operates from the mains - which creates inconvenience, but at the same time increases the productivity of the equipment. The main part of such systems is the thermostat. Depending on the temperature regime, it sends an electromagnetic pulse to the gas valve. But with the help of a special program, it is possible to program the temperature mode for several days in advance, weeks or even months.

The non-volatile wireless boiler control system functions on the same principle as the wired one. The only difference is that the control module of the wireless version is located in any place convenient for you, while it is not connected by a wire to the device.

Some devices provide for the installation of a GSM module, which provides access via mobile gadgets (smartphones, tablets). To find out the latest data on the state of the device, you just need to go to the application on your smartphone and enter the desired password.

Through mobile devices, it is possible not only to control gas burners with automatic heating boilers, but also to control them. And if a special situation arises, the system will automatically send you a notification in the form of an SMS to your number.

Today, modern technologies can provide full automatic control over an autonomous heating system, without creating additional efforts.

The heart of any gas boiler is a burner with a heat exchanger installed above it. The burner burns the gas fuel by generating heat. In turn, the heat is absorbed by the heat exchanger and sent to the heating system. It is the burners that the current review will be devoted to.

We will tell you what a gas burner for a solid fuel boiler is, and also give information about the types of burners for gas boilers.

What is a gas burner

The gas burner is one of the most important components of any boiler. She is responsible for creating a stable flame. It is here that the combustion of the supplied fuel takes place. The resulting heat rises up to the heat exchanger, where it almost completely passes into the coolant. Combustion products, together with heat residues, are discharged into the atmosphere in one way or another.

The device of a gas burner for a boiler is extremely simple - it includes several main components:

Low emission of nitrogen oxides and carbon monoxide gases during combustion makes the boiler almost flawless in environmental terms.

- Nozzle - gas is emitted from here;

- Ignition system - provides gas ignition;

- Automation system - controls the temperature;

- Flame detector - monitors the presence of fire.

To put it simply, this is how it looks. And how different types of gas burners differ from each other in different models of boilers, you will learn a little later.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, the noiselessness of work is important. Some models of Soviet instantaneous water heaters, where the flame rustled with the force of a hurricane, immediately come to mind. Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops and explosions). The design of the combustion chambers has an additional effect on the noise level.

Long service life - if you remember the old gas units, they served for quite a long time (in those days, everything was done for centuries). Today, there are no such technologies anymore, so burners in boilers often break down. There is only one way out - to buy units from trusted brands, where components of normal quality are used. As for any Chinese junk from unknown manufacturers, everything is obvious here - you shouldn't take it.

The same applies to cheap Russian-made boilers - short-lived burners are often installed in them.

Complete combustion of the gas is another important requirement. A burner for a gas boiler must burn the fuel completely, with a minimum of carbon monoxide and other related components. However, everything here depends not only on it - other components also influence the quality of combustion. We must not forget about proper gas discharge, for which you need to have a clean chimney with good draft at your disposal.

As for the principle of operation of a gas burner, it is simple:

In the burner, the combustion gas is combined with air. At high temperatures, a chemical reaction takes place to form carbon dioxide and water.

- The boiler detects a discrepancy between the temperature in the heating circuit and the parameters set by the users;

- The gas valve opens, gas begins to flow into the burner;

- At the same time, the ignition system is activated;

- The gas is ignited and a flame is formed.

At the same time, the control of the presence of a flame begins to work - if the fire suddenly goes out, the automation will cut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be shut off.

Flame control is implemented differently in gas burners. Somewhere there is a simple thermoelement, and advanced boilers with electronics-based automation are endowed with ionization control systems.

Classification of gas burners

For a long time, the market was dominated by the simplest boilers, devoid of complex electronics and advanced automation. They needed full-fledged chimneys and had to be installed in rooms with good ventilation. Today, there are units on sale that can be operated in almost any conditions. Traditional models are sold along with them. All of them differ in the design of gas burners.

Atmospheric gas burners

The use of atmospheric gas burners greatly simplifies the design of heating equipment. They work due to the natural flow of oxygen, and full-fledged chimneys are used to remove combustion products. Since oxygen is taken from the room, there must be good ventilation in it. Let's take a look at the main advantages of atmospheric boilers:

- Simplicity of design - has a direct impact on the cost of equipment;

- Low noise level - there are no additional fans, only the flame hums;

- Higher reliability - here a completely understandable pattern is triggered that equipment with a minimum of parts breaks down much less and less often;

- Non-volatility - thanks to this, the equipment can work in buildings in which there is no electrification.

There are also some disadvantages:

- Not the highest efficiency - you have to put up with this drawback. More advanced gas boilers with closed burners are more economical and efficient;

- The need for a full-fledged chimney that goes to the roof - in houses under construction, this is an additional cost;

- The installation of a boiler with an atmospheric gas burner should be carried out in a specially designated room where there is ventilation and a window - sometimes it is problematic to follow these requirements.

It is also necessary to note the possibility of incomplete combustion of gas fuel.

"Turbocharged" burners

We have come close to the most modern heating equipment equipped with closed-type gas burners. Such boilers are often called "turbocharged". They are equipped with compact chimneys, often extending directly behind the opposite wall. This is very convenient, especially when the building is under construction - no need to worry about arranging the chimney and ventilation ducts.

A heating boiler with a closed combustion chamber is a heating unit in which a gas burner is enclosed in a special chamber. Oxygen is supplied here from outside, through a special coaxial chimney. Combustion products are removed through it. A powerful fan with automatically controlled speed controls all flows. If desired, the "turbocharged" boiler can be mounted in an absolutely sealed room, devoid of ventilation and windows.

The coaxial chimney is a kind of "pipe in pipe" design. It serves for intake of outside air and for removal of combustion products. Such a chimney is displayed at an arbitrary point of the nearest wall, but not closer than half a meter to the nearest windows (more stringent requirements may be imposed).

Advantages of gas boilers with closed burners:

- Can be installed in any room - in kitchens, basements, bathrooms (even in the bedroom);

- Increased safety - gas burns in an isolated chamber. Even if it goes out, and the automation does not react to it, the gas-air mixture will be removed outside the apartment / house;

- Increased efficiency - gas boilers with closed burners are indeed more efficient, but this does not apply to all models;

- More efficient temperature control - for this, a fan speed control system is used here;

- High environmental friendliness - the fuel burns almost completely.

Unfortunately, there were some shortcomings:

For increased security and increased efficiency, you will have to pay with high noise levels and increased service bills.

- Increased complexity - gas burners for heating boilers have a more complex structure, which makes it difficult to carry out repair work;

- Slightly reduced reliability - the more details, the lower the reliability of the system (the cheapest models and Chinese models are often fail);

- High price - in order to buy a “turbocharged” boiler, you have to pay a round sum (they cost 10-15% more than their atmospheric counterparts);

- Increased noise level - the fan installed in the system makes a hum (the noise level depends on the specific model);

- Lack of non-volatility - when the light is turned off, the equipment will stop its work. The problem is solved by installing an uninterruptible power supply.

Despite this, the use of these boilers for heating houses and apartments is becoming a certain trend.

Closed-type burners are equipped with the so-called condensing boilers, which are characterized by increased efficiency due to the selection of heat from the combustion products.

Other differences

Consider the separation of gas burners by type of ignition. The easiest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two downsides here - increased gas consumption and low safety (the ignitor may go out). The primary ignition is carried out with matches or with the help of a piezoelectric element giving a spark.

Natural gas from the highway gives smooth combustion without forming excessive soot on the walls of the chimney.

Electronic ignition of the burner provides for the presence in the gas boiler of a high voltage converter. Energy is taken from batteries or the mains. The first option is used in non-volatile boilers in which there is no electronic automation. The second option is relevant for complex units with electronics on board. Along with such ignition, flame ionization control modules are often installed.

There is also a division according to the type of fuel used. Natural gas supplied from the mains is cleaner, it is supplied with optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot. The equipment is connected to the network without alterations. There are burners that can work on propane - for this you need to configure the system and install the nozzle. The flame from the burning of propane gives off yellow, there is an increased deposition of soot in the chimney.

Jets allow you to normalize the propane pressure to an acceptable value - they are supplied as a set or purchased separately.

Gas burners for universal boilers

A gas burner for a solid fuel heating boiler is a rather complex unit. It was created to transfer heating equipment from one type of fuel to another. That is, you can purchase a solid fuel (universal) unit for working on wood, and when a gas main appears, transfer it to work with natural gas.

The maintenance of even the simplest gas burner is best entrusted to the master - the services of a specialist will be cheaper than buying a new unit.

The automatic gas burner for a solid fuel boiler is built according to a fan circuit. Gas is supplied here, mixed with air, after which the finished fuel-air mixture is sent to the nozzle. Here it is ignited, forming a high-temperature flame torch. On board the burner there is a powerful fan, automation system, gearbox and gas filter. The unit requires electricity to operate.The product itself has a modular design (removable).

A typical example is a gas burner for a Cooper boiler. The boiler itself is a pellet, but you can connect a replaceable burner to it and transfer it to natural or liquefied gas.

In a summer house or a fully-fledged private house, if you do not live in it all year round or nearby there are no central heating pipes to connect the building to them, then installing a compact gas heater is a suitable option. It will come in handy in the cold season from time to time. And in the summer, cool weather happens. It is useful for giving when it is required to dry the room. It is too laborious to start the construction of a full-fledged heating circuit if the house is small. The gas heater, powered by a cylinder, easily moving from place to place, is much more suitable for such conditions. More often, as a portable heat source, units operating on natural gas acquire.

Basic equipment of the average of the housing, burner, heat exchanger, heating element and gas cylinder. In addition, the heater is equipped with a thermostat and an automated gas shut-off mechanism.

Buyers choose gas heaters for a small price, compactness, clear operating principle and good efficiency. The following types of gas heaters are available:

- Gas catalytic heater

- Infrared device

Heating appliances are divided into outdoor and indoor appliances.

Italian gas convector for summer cottage

This type of heater resembles a typical battery, it is also placed under the window opening. Natural gas gas convectors use both gas from a gas pipeline and a liquefied version as fuel. Gas burns in an insulated container, heating the air that separates the chamber from the apparatus. The convector heats a small room in a matter of minutes, which is convenient if the cottage is visited in cool weather, and there is a need to quickly warm the room. The convector independently maintains the necessary temperature conditions. When the desired heating temperature is reached, combustion becomes less intense. If the fire goes out, the protective system is activated, and the device turns off.

Catalytic gas heater

This type of device is powered by gas or gasoline. With it, you can heat a room of any size: from a small hut to a large warehouse. Heat generation occurs due to the catalytic combustion process. It is distinguished by the absence of flames and any sounds, but with the active release of a large amount of heat. Heat is generated due to the oxidation of the fuel that is on the surface of the panel. The catalyst, which is part of the surface material, provokes oxidation. All processes take place on the solid surface of the panel without flowing into gaseous forms.

Such devices are safe, not subject to spontaneous combustion, do not pollute the environment.The heating element of the catalytic heater is a catalytic panel made of fiberglass with the addition of platinum. At the moment, instead of platinum, more relevant catalysts are used, which contribute to deep oxidation and not. Some models are equipped with a fan heater in order to increase power. A gas heater is able to quickly heat indoor air.

By their characteristics, the catalytic devices are close to infrared heating devices. They are inferior to them in the speed of heating the room, but they are silent.

Infrared model with thermostat and ceramic burner: from the cylinder and the line

Infrared or powered by a gas pipeline. Models with an infrared ceramic gas burner are distinguished from other infrared devices by the presence of an open flame during operation. Such devices serve for a long time and heat efficiently, in a short time evenly filling the entire room with heat. Despite such attractive features, a gas ceramic heater is not the most popular. The reason is the high price. But the burner is worth it: it is independent of electricity, does not dry the air in the room, and is easy to install.

An infrared device is suitable for heating large-scale premises: hangars, hypermarkets. The market offers a wide range of devices with various configurations and mounts. It is not difficult to choose an infrared ceramic gas heater that fits perfectly into the interior and will meet all technical requirements. Such a heater can be installed both on the floor and on the wall or ceiling.

Radiation occurring on the surface of a heating element. If other heaters for cottages warm the air itself, then infrared equipment heats objects in the room, which then give off heat to the room itself.

At the cottage, an infrared heating device is doubly convenient: it can be used not only at home, but also put in the gazebo to warm it in cool weather.

Most street heaters used in cafes or at stopping complexes are infraredOutdoor gas heater Foreman: an inexpensive option

A street heater is indispensable for those who like to spend a lot of time in the fresh air, have picnics, and grill barbecue on an open fire. With such a device, you can not deny yourself the pleasure of being outdoors even in very cool weather, prolonging the summer season. In appearance, the street gas heater resembles a street lighting pole. The fuel is in the tank, which is located at the base of the structure. It is filled with gas as needed.

Outdoor heat sources are used not only on suburban areas, but also on the summer porches of cafes, children's play areas in the fresh air.

In addition to full-fledged street heaters, there is a portable gas heater. Most often, compact devices of the kovea brand are found. The small gas heater is ideal for a tent to keep warm during fishing or hunting. This company also produces other tourism products, such as an infrared burner for cooking in camping conditions.

Gas cylinder stove: Chinese and other options

A gas stove for giving with a cylinder is a good alternative to a classic brick stove. By the principle of operation, such a device resembles a gas boiler. The design of the stove includes: a burner with a firebox, a heating shield and the housing itself.

There may be several reasons to put gas stoves in the country:

- She quickly warms up the room

- No need to clean chimney pipes, unlike a brick kiln

- Can adjust the temperature

- Easy to relocate if necessary

- Safe to use

- Does not require electricity

Models are heat and not heat. Heat-intensive ones accumulate heat in themselves, cooling more slowly.

Rules for choosing the best heater: price and quality

The main thing when choosing a heater is to correctly calculate the required power. Traditionally, when determining this parameter, a standard flow rate is used: 1 kW per 10 square meters. m. It is better to add a little more in reserve to the resulting number. To cover the heat loss that will inadvertently occur during operation of the heater.

Direct or indirect heating. It depends on the type of heating whether the device will take air directly from the room and release products arising during combustion into it, or whether the unit involves the removal of combustion products. For the direct type of heating, ventilation is required. They are not recommended for use indoors.

It is important to make sure that it is possible to conveniently connect the heater to the network. If the unit operates on cylinders, then cylinders are purchased with it, their compatibility with the device is checked.

Additional features. The presence of a thermostat, an emergency gas shutdown mechanism is what you should keep in mind when buying. Some devices operate with multiple fuel options. The protective algorithm takes into account several factors independently of each other: the tilt of the device, the flame level, and the cessation of fuel supply.

WATCH THE VIDEO

Gas cottages are a great way to heat a room.

Life away from the equator dictates its own laws. Following the decrease in street temperature, the houses inside cool down. In this review, we will consider a solution to the problem by choosing the best gas heaters - from portable (for tents) to convectors for homes or summer cottages that can replace a gas boiler.

Types of gas heaters

Gas convectors

Such heaters may have a closed and open combustion chamber. Closed-type models for burning gas take air from the street and remove combustion products there through a special pipe laid through the wall. They are well suited for home or garden and are able to become an alternative to a gas boiler. Models with an open combustion chamber are not very suitable for living quarters or require the use of a vertical chimney.

Catalytic Gas Heaters

Devices of this type operate due to the oxidation of substances on the surface of the catalyst, in which a large amount of heat is released. The process takes place almost silently and without flame. The catalytic combustion method is more reliable, efficient and safe compared to conventional infrared heaters.

Ceramic Gas Heaters

By analogy with electric counterparts, such heaters work due to directed thermal radiation and heat not air, but the surfaces of walls, objects, as well as people present in the room. Only a gas burner acts as a heating source. The use of ceramic plates allows for complete combustion of the fuel and eliminates harmful emissions.

Heat gas guns

They have a cylindrical shape and work on the principle of a fan heater, in which the role of the heating element is played by a gas heat generator. They work from bottled gas, and the power is usually regulated by a gearbox.