Do-it-yourself installation of metal-plastic pipes. Couplings for connecting polyethylene, plastic and steel pipes Joining metal pipes with compression fittings

If you decide to replace the plumbing or heating system in your apartment, then our article is for you.

In it we will tell you how the installation of metal-plastic pipes is carried out, what is needed for this, specifications pipes and their repair.

I would like to say right away that the installation of metal-plastic pipes is not difficult work, but it is responsible and even a beginner can do it. And the first question: "How to choose metal-plastic pipes?"

Reinforced-plastic pipes - aluminum pipes with two protective layers of polyethylene: inner and outer. The layers are connected to each other using special glue, which helps to improve the technical characteristics of the pipe.

Thanks to the smooth inner layer, salt deposits and rust do not accumulate in the pipes. The outer layer protects aluminum from condensation and external irritants (ultraviolet light, high humidity), thereby extending its service life.

The main advantage of these pipes is their high flexibility, that is, you can bend the pipes at the desired angle, do not require special equipment, the pipes are electrically safe, do not require painting, have a long service life (more than 50 years) and are relatively inexpensive.

The disadvantages of these pipes are as follows: their maximum operating parameters are 10 bar, temperature is 95 degrees. They are sensitive to freezing of water, they can be easily cut with a sharp object, pipes with a fitting cannot be bent, when exposed to high temperatures, they are deformed.

But, despite these shortcomings, metal-plastic pipes are in great demand among those who decided to perform work on replacing water pipes on their own.

Speaking about the methods of connecting metal-plastic pipes, it is worth noting that there are only two of them.

Namely:

- Press fitting.

Let's consider them in more detail.

In this way, by using threaded fittings. The advantages of this option are ease and speed of assembly, as well as you do not need to purchase special equipment.

Of the tools you will need:

- Scissors for cutting pipes or a hacksaw for metal;

- Calibrator to correct edge deformation after trimming;

- Measuring tape (tape measure);

- Spanners;

- Stripping knife.

When installing metal-plastic pipes, the instructions will be simple.

First, we make a plan for their location in the room. Then we measure the required length of the pipe and cut it off with a hacksaw or special scissors. Usually, when trimming, the edge is deformed. With the help of the calibrator, we give it its original, round shape.

Now we take the desired fitting and remove the nut and clamping ring from it. We carefully put them on the pipe. Be sure to finish the pipe edge before connecting the pipe to the fitting. It should be free of sharp edges and burrs. For these purposes, use sharpened metal drills or a round file of the required diameter.

Now you need to put the pipe on the fitting and align it with the fitting squeeze. Now you can return the pressure ring to its place and tighten the nut. First, we do it by hand, and then with a wrench. It should be tightened until the characteristic crackling appears.

But do not put a lot of effort, otherwise you can break the thread, which means this part will have to be thrown out.

Sometimes, during installation, especially at the introduction of pipes into an apartment, it becomes necessary to connect metal-plastic pipes with metal ones.

For this, we use special adapter fittings. On a metal pipe, you will need to cut a thread, and the process is the same. For branching, transitions from one diameter to another, and turns, also use special fittings.

It is possible to bend pipes at right angles without corner pieces. But then do not forget to install a special spring at the bend. It will not allow the pipe to be pinched at the bend.

It is not advisable to use this connection for the installation of heating pipes and hidden pipelines. It is wiser to use it, which do not hide in the walls.

Advice! Work on the installation of metal-plastic pipes must be carried out at a temperature of at least 10 0 C. Before starting the installation, turn off the water supply at the entrance to the apartment or the riser in the basement. But with the latter option, do not forget to warn the neighbors.

Press fitting

The conditions for installing a press fitting allow such pipes to be hidden in walls and poured with concrete. It is more reliable than a compression fitting.

But it will require special equipment for the installation of metal-plastic pipes.

But the quality of the connections increases, the number of parts and materials (pipes) used decreases, which significantly reduces the cost of installation costs.

For installation, we need special crimping couplings, a pipe cutter or a hacksaw, manual or electric press tongs. We measure the required pipe size and cut it off. The edge of the pipe is processed with a calibrator in order to eliminate the deformation that occurs after cutting. We put a crimp sleeve on the pipe.

After that, we insert a fitting with a rubber seal and squeeze the coupling using a press pliers. A ring should appear on the coupling, it will be pronounced. It should be noted that crimping is only allowed once!

The fitting can be of various shapes, which allows you to install the pipeline of any configuration. Some manufacturers initially attach the sleeve to the fitting. Therefore, the connection process will be slightly different from the above.

In this case, we cut the pipe, calibrate and clean the edges. Then we put the pipe on the fitting union. The tightness of the fit can be controlled through the holes in the crimp sleeve.

With this type of connection, it is possible to carry out installation with metal-plastic heating pipes, and not just water pipes. They can also be used for heated floors.

Advice! Despite the better connection than with compression fitting, some people do not want to use this method when replacing pipelines due to the fact that they have to buy press jaws. If you intend to use this particular installation method, ask specialized stores if they rent this equipment. Many hosts have been providing this service for a long time.

The pipeline is installed. It seems to you that now everything will be in order, but no one is immune from the vicissitudes of fate. Therefore, we propose to consider ways of how to repair a metal-plastic pipe.

There are several of them:

- Epoxy adhesive - perfect for sealing small leaks in a pipe. To do this, we shut off the water supply, having previously marked the place of repair. We dry the surface, a hair dryer is perfect for this. Apply a layer of glue to the leak, wrap it with a bandage and apply glue again. After 11 hours, you can turn on the water. The leak is eliminated.

- Flange - temporary repair. For this we need a factory pipe repair flange. We put a rubberized gasket on the place of repair, put on and tighten the flange. The leak can be eliminated for a long time, but in the future it is better to replace this section of the pipeline with a new one.

- Bandage, also a temporary option. Cut out a rectangle of the desired size from car or bicycle rubber. It is applied to the leak and fixed with wire or clamps.

- Replacing a damaged pipe section is the most reliable method, but it requires financial costs. Buy a pipe of the required size and fittings (fitting). Cut out the damaged area and replace it with a new one.

When using flanges and bandages, one must be careful not to deform or pinch the pipe. Calculate the contact pressure.

As you can see, the installation of metal-plastic pipes is not difficult, but it requires care and attention. Do not be afraid to learn new things, it will come in handy in life.

In the process of repairing a water supply system, metal-plastic pipes are very often chosen today. It's no secret that pipes made of metal-plastic are much more durable and easier to use than their metal counterparts. In this article we will tell you how to install plastic and metal.

But not everyone knows how to connect metal-plastic pipes with metal ones. Moreover, this operation is completely uncomplicated and within the power of any home craftsman.

Installation of pipes made of metal-plastic

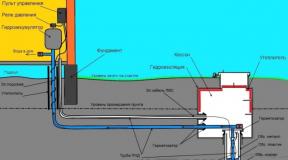

Before starting to lay plastic pipes, they must be unwound from the coil. In the case when the coils were in the cold, they must be kept for about a day in a room at a temperature of at least 15 C. When unwinding, it is necessary to ensure that the pipes do not twist.

During installation, no straining must be created. When laying to dirt and debris did not get inside the pipe, you need to put plugs on its ends. As a rule, plastic products are laid in special shafts, grooves or channels, from where it is necessary to provide access to all detachable connections and fittings, for this you need to install removable doors and shields.

Due to the elasticity of metal-plastic, the installation of heating systems and water supply systems can take place either according to the collector or according to the classic tee scheme. Laying of plastic pipes is as simple as possible, since during the installation the number of joints is minimal.

How to connect a plastic pipe to a metal

Most popular options connections of metal-plastic pipes with metal are such:

- using press fittings;

- using compression fittings.

The first of these connection options is divided into two more:

- using a press fitting, which is of the push-on type;

- using a crimp sleeve.

Installation tool

Installation of metal-plastic pipes is a very simple procedure that does not require special tools. When connecting with compression fittings for installation, you may need:

- pipe cutter, it can be successfully replaced with a hacksaw for metal;

- a wrench, and the usual tools that are always in the kit of any master.

When connecting with press fittings, these tools still need add press jaws and expander, it is used to enlarge a hole in a reinforced plastic pipe.

Fitting

The connection of metal-plastic pipes with metal ones takes place using special devices called fittings. They may have different configuration and provide fastening, both in a linear plane and at an angle of 90 degrees. Compression fittings (for clamping) are the most popular with craftsmen. Press fittings (for pressing) are also very often used.

Pressing in and connecting the plastic with the clamping fitting takes place by screwing in the union nut. In press fittings pressing takes place by compressing the outer sleeve, and is done with a special tool.

The fitting design is very simple. The fitting consists of only a ring, nut and union. You don't need any special tools or experience to work with these compounds. All work is done with a simple wrench.

The advantage of these fittings is that, with the simplest installation, they are also very easy to disassemble. But, their disassembly is undesirable, since in this case it is imperative to replace the gasket, but at the same time this advantage of the fittings, which consists in the possibility of their dismantling, can be used, since today it is possible to pick up any gasket without much difficulty.

The advantage of these fittings is that, with the simplest installation, they are also very easy to disassemble. But, their disassembly is undesirable, since in this case it is imperative to replace the gasket, but at the same time this advantage of the fittings, which consists in the possibility of their dismantling, can be used, since today it is possible to pick up any gasket without much difficulty.

Fittings are used not only for laying water supply systems, but also for their repair. If found defect in any part of the water supply, then it is simply removed, changing to a new section, which is attached using the same fittings. This approach avoids dismantling the entire plumbing system.

Damaged thread size should not be more than 10% of the total length... The ends of the fittings must certainly be flat and perpendicular to the axis of the product itself. Burrs are not allowed on the threads.

Taking into account the connection option, fittings are divided into compression and screw fittings.

Tightness, when using screw connections, is ensured by pressure, appearing on the expansion ring when screwing in the nut... A special gasket is installed to create a strong connection between the fitting and the ferrule.

Fastening of metal-plastic pipes with metal using compression fittings

Before connecting the pipe to the fitting, its end must be cut so that the cut is perpendicular to the pipe axis. It is advisable to use a special pipe cutter for this.

Before connecting the pipe to the fitting, its end must be cut so that the cut is perpendicular to the pipe axis. It is advisable to use a special pipe cutter for this.

But this procedure can be done quite successfully with a hacksaw for metal, but make sure that there were no chipping or rags around the edge... The cut will be cleaner if you install a new blade on a hacksaw. A jigsaw is not suitable for cutting, it will not provide such accuracy.

When preparing to perform work, you need to take into account one nuance. European products in the field of pipe production do not have uniform standards, so the sizes of parts from different manufacturers may be incompatible. therefore it is necessary to strive for pipes and fittings to be of the same manufacturer... If this is not possible, then when going to buy fittings, you need to take a piece of pipe with you in order to compare the wall thickness and dimensions. In addition, you need to know that there are one-piece fittings on the market.

Before attaching the pipe to the fitting, the cut end must be machined and leveled, as well as a small chamfer to smoothly connect the pipe and fitting. Burrs are always removed inside the pipe. After that, a ring and a nut are put on the pipe... Only then can the pipe be pushed onto the fitting. The nut is put on only by hand, without the help of a key. For a certain time, the nut will tighten easily if there is no distortion. At the end, it must be tightened with a wrench, while remembering that the pipe is made of plastic, as a result of this, the press must be made quite soft.

Fastening of reinforced-plastic pipes using press fittings

Press fittings are made very often. This makes it possible to install underfloor heating, water supply and heating systems. The advantages of this type of connection are that this plumbing can be installed under concrete or drywall, and in the fact that the amount of used fittings is reduced, which reduces the cost of plumbing.

Press fittings are made very often. This makes it possible to install underfloor heating, water supply and heating systems. The advantages of this type of connection are that this plumbing can be installed under concrete or drywall, and in the fact that the amount of used fittings is reduced, which reduces the cost of plumbing.

Fastening with press fittings includes the following work:

- a part of the pipe of the required size is cut off;

- using a calibrator, the inside chamfer is removed and the roundness, deformed during cutting, is restored;

- a clamping sleeve is installed at the end of the pipe;

- the fitting of the fitting with sealing rubber rings is attached;

- with the help of press pliers, the coupling is clamped, as a result, convex rings appear on the coupling, and the metal bends.

It must be remembered that the clamping of the coupling with the press pliers is done only once.

Fastening with sliding sleeves

In this version, for work will be press tongs and expander required, it serves to expand the hole inside the pipe.

During the process, the following sequence of work is observed:

- the part of the pipe is cut off where the coupling is put on;

- the end of the pipe is processed with an expander;

- the pipe is placed on the fitting;

- pressing tongs the coupling is pressed onto the fitting.

How to choose a press pliers

Since pressing tongs are an important tool, choosing them correctly will ensure the proper quality of all installation work. Most pipe fitting tool manufacturers make both professional and standard types of this equipment:

- Electrical;

- Hydraulic and so on.

For a one-time installation of a water supply system, it is quite enough to choose manual press tongs, since a professional tool will cost you much more, and when working with this tool, you need to have certain skills and special skills.

For a one-time installation of a water supply system, it is quite enough to choose manual press tongs, since a professional tool will cost you much more, and when working with this tool, you need to have certain skills and special skills.

According to experts, in terms of the quality of the fasteners made, manual press tongs are no worse than a professional tool. They are very easy to operate and work with them is not particularly difficult.

Before buying a press tongs, you need to find out the maximum cross-section of pipes that will be installed in the water supply system, and taking this parameter into account, choose the right tool. You need to know that for fastening pipes with a smaller section additional tabs must be attached to the press jaws.

The main mistakes when fixing plastic pipes

As we said above, the connection and laying of metal-plastic pipes is a rather simple procedure that can be done by any home craftsman, even without special experience in this area. Wherein knowledge of basic mistakes, which are allowed when performing these works, will make it possible to ensure the reliability of the installed water supply system.

The main mistakes are:

- poor processing of the trimmed part, is fraught with poor tightness of the installed system;

- an attempt to exhaust the coil of a cold pipe, this can violate the integrity of the walls;

- multiple assembly and disassembly of threaded fasteners without replacing the seal gaskets;

- pinching the thread connections, which leads to its deformation;

- an attempt to repeatedly clamp the fastener, which leads to a violation of the integrity.

Summarizing

So, as you can see, laying a water supply system from metal-plastic pipes, which are a reliable and inexpensive material, meets all hygienic standards, and can be easily done by any home craftsman, even without much experience. The quality of the assembled water supply system will depend only on the accuracy of the person involved in this process and on his compliance with the rules and installation procedure.

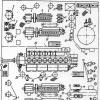

Installation of the pipe (fig. 10) is carried out using special compression-type brass fittings. These fittings consist of a union, split ring and flare nut and provide a secure connection between pipes and fittings using a common wrench. When tightening the union nut, the press sleeve (O-shaped cut ring) is compressed on the pipe and ensures the tightness between the fitting and the inner wall of the pipe.

Fig. 10. Connection of a multilayer pipe with a compression fitting

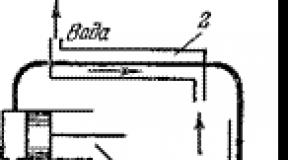

The main advantage of this connection is that no special equipment is required during installation, and, if necessary, it is possible to dismantle any connection. Once assembled, the assembly can theoretically be disassembled and reassembled, but, as practice shows, it is better not to touch the connection. Therefore, in the case of pipeline repair, you need to cut out the damaged part and insert a new one, connecting it with fittings. When connecting a pipe to a used fitting, the gaskets on it must be replaced with new ones (fig. 11).

Fig. 11. Gaskets on the fitting spigot

The pipe is cut perpendicular to the axis with a special pipe cutter for composite pipes, in extreme cases, a hacksaw with a fine tooth. The pipe is bent by hand or using a special spring - a pipe bender. Two types of springs are used: some are inserted inside the pipe (practically not used), others are put on the pipe from above. The minimum bending radius of a pipe without a spring is 5 outer diameters of a bent pipe, with a spring - 3.5 diameters.

On the Russian construction market, there are almost all types of compression fittings produced in the world. In principle, their designs differ little from each other, but there is still a difference: manufacturers produce detachable and one-piece fittings (Fig. 12), but this is not the main thing. When purchasing pipes and fittings for them made in different places, you should make sure that they are compatible, since different manufacturers have the outer diameters and wall thickness of pipes, even for the same nominal pressure, may not match. In other words, it is better to buy fittings and pipes, if possible, from the same manufacturer.

Fig. 12. Diagrams of compression fitting connections of various manufacturers

When fixing metal-plastic pipes, a minimum of clamps and clamps are required, since the pipes perfectly retain their shape. The installation of the pipeline is carried out both according to the collector and the tee installation scheme. When installing tee circuits (in the language of plumbers, this circuit is called a "comb"), fittings can be sequentially connected to the pipe or first mount the pipeline and then cut the fittings into it (Fig. 13).

Mark the installation location of the fitting

Put on a heat-insulating corrugation (optional item)

Fig. 13. Example of connecting a compression fitting

The sequence of connecting metal-plastic pipes with compression fittings:

1. Align the pipe with a minimum 10 cm straight line before and after the cut.

2. Cut the pipe at a right angle according to the markings.

3. Work the end of the pipe with a reamer, first with the calibrated side with chamfering no more than 1 mm, then with the other side at least to the notch, ensuring the correct rounded shape of the pipe.

4. Slide the flare nut and split ring onto the pipe.

5. Moisten the fitting.

6. Place the pipe on the fitting so that the end of the pipe rests flat against the edge of the fitting. Tighten the union nut by hand until it stops on the fitting. The nut should be easy to tighten, if this does not happen, then you are not twisting it along the thread. Further forceful tightening of the nut will lead to damage to the thread and, as a result, to leakage of the connection and subsequent replacement of the fitting.

7. Holding the fitting body with one wrench, use the other wrench to tighten the union nut 1–2.5 turns so that 1–2 threads are visible. The use of wrenches with additional levers is not allowed - do not apply excessive force or overtighten the nut.

To avoid fogging of pipes or to insulate them, special corrugated hoses are put on the pipes, most often made of foamed polyethylene. If the corrugation was not installed for some reason, and the need for it appeared, then it can be mounted later. To do this, the corrugated pipe is cut lengthwise and put on the pipe, after which it is reinforced with tape.

Figure 13 shows the installation of a tee fitting, in fact, the range of compression fittings is quite rich, it allows you to assemble a pipeline of almost any complexity.

Nipple with female thread (transition to pipe fittings) 16 × 1/2; 20 × 1/2; 20 × 3/4; 26 × 1; 32 × 1

External thread nipple (transition to pipe fittings) 16 × 1/2; 20 × 1/2; 20 × 3/4; 26 × 1; 32 × 1

Coupling (connection of two metal-plastic pipes) 16; 20; 26; 32

Elbow with female thread (transition to pipe fittings) 16 × 1/2; 20 × 1/2; 20 × 3/4; 26 × 1; 32 × 1

Elbow with external thread (transition to pipe fittings) 16 × 1/2; 20 × 1/2; 20 × (3/4; 26 × 1; 32 × 1

Elbow (connection of two metal-plastic pipes) 16; 20; 26; 32

Female tee (transition to pipe fittings) 16 × 1/2; 20 × 1/2; 20 × 3/4; 26 × 1; 32 × 1

Tee with an external thread (transition to pipe fittings) 16 × 1/2; 20 × 1/2; 20 × 3/4; 26 × 1; 32 × 1

Tee with the same fittings 16; 20; 26; 32

Reducing tee from 16-20-16 to 26-32-26

Crosspiece 16; 20; 26; 32

Elbow (water socket) for fixing the mixer and other devices 16 × 1/2; 20 × 1/2

Double angle bracket for fixing the mixer and other devices

16 × 1/2; 20 × 1/2

Sweep 16; 18; 20; 26

Caliber 16; 18; 20; 26

Spring for bending metal-plastic pipes 16; 20; 26; 32

Fittings are marked according to two indicators: by the outer diameter of the attached metal-plastic pipe and by the size of the thread, which the fitting is connected to a metal pipe, a squeegee, a ball valve or other pipe fittings. For example, in the explanations to Figure 14 for a nipple with an internal thread, there are numbers 16 × 1/2, indicating that a reinforced-plastic pipe with an outer diameter of 16 mm is attached to this fitting on one side, and pipe fittings with a 1/2 thread on the other side inch.

When assembling the water supply and sewage systems, it is required to ensure the reliability and tightness of the system. The most critical places are the branching of the pipeline, the connection of elements along the length, the places of connection to plumbing fixtures, the areas of change of direction. Recently, pipes made of polymers occupy a leading position in the market due to their characteristics. In order for them to “show themselves in all its glory”, it is required to select the corresponding connecting elements to them.

Compression fittings - very practical fittings in the water supplyThe structure and principle of operation of the fitting

The principle of work lies in the name. Compression - a word derived from the Latin root, which translates as "compression". Tightness is ensured by crimping. The main load is taken by the thrust (compression) rings. This element prevents the movement of the pipe in any plane, does not allow spontaneous unscrewing of the pipeline parts.

Compression fitting includes the following elements:

- A housing on which a limiter for the pipe and thread are provided, of a trapezoidal cross section.

- An o-ring (gasket) is installed between the housing and the press-in sleeve. The material of manufacture is rubber. The product provides reliability and tightness of the connection even when bending the pipeline.

- The clamping (crimping, compression, thrust) ring prevents any pipe movement.

- The press-in sleeve limits pipe deformation. Made of the same material as the body. The part stably fixes the gasket.

- Clamping nut (cover) - a part that has an internal thread and external grooves in order to ensure convenient twisting.

Advantages of using compression fittings for polyethylene pipes

- used for various pipe materials;

- resistance to corrosion (rust) due to the absence of metal parts;

- safety, used for drinking water;

- compounds are disassembled up to 10 times, which allows us to talk about reusable use;

- repairs are carried out by replacing a failed part;

- strength and reliability;

- to temperature changes, chemical influences;

- fittings for the compressor are convenient to install, during installation they will not cause problems and will not require special equipment;

- wear resistance and resistance to mechanical stress.

Types of products from cross-linked polyethylene, connected with a crimp wrench and a sleeve

Classification is made depending on the site, which requires the installation of connecting elements. Types are as follows:

- couplings for joints along the length;

- tee to create branches;

- corner (elbow) for changing the direction of the pipeline;

- t-shaped connections for branches;

- stubs.

Types of compression fittings are also distinguished depending on the material of the pipes and the connecting products themselves. Metal types of connecting elements are made of nickel-plated brass, copper, steel. The metal fitting is suitable for the following types of pipes (the material for the manufacture of connecting parts is indicated in brackets):

- installation of external engineering networks (brass with nickel plating);

- metal-plastic (use brass with nickel);

- copper (copper, steel, brass);

- steel (steel, brass).

Advice! The metal compound is mainly used for repairs. For example, when you want to replace a section of a metal pipe with a metal plastic, it is reasonable to use crimp products.

In addition to metal, products are made from polymers. It is better to choose products from the same material from which the pipeline is made: polyethylene - for pipes made of polyethylene, polypropylene - for polypropylene. If it is necessary to connect polymer pipes with another material, plastic products with metal internal thread are selected. Compression fittings can withstand high pressure on pipe connections.

How to choose steel outdoor fittings from the manufacturer Wak

- Before going to a specialized store, they draw a water supply scheme that will help you understand how many fittings and what design is required.

- Pipes and fittings are selected so that they are manufactured by the same manufacturer.

- When choosing, pay attention to the outer diameter and wall thickness. The SDR parameter shows the ratio of the pipe wall thickness to the outside diameter of the pipe.

- The seller is required to present quality certificates and passports for the products. Even if you purchase inexpensive parts of unpopular brands that have all the necessary certificates, you can be sure of their quality and reliability.

The price of compression fittings depends on:

- product diameter;

- material;

- destination for various sections of the pipeline;

- manufacturer.

For brass, the following values \u200b\u200bcan be given:

- domestic producers 50-500 rubles apiece;

- foreign manufacturers 250-2500 rubles apiece.

Plastic fittings are cheaper. The price also depends on the presence of metal inserts in the element. The price is in the range of 20-1600 rubles apiece.

WATCH THE VIDEO

Technology for the correct installation of copper, brass threaded fittings for plastic pipes

Installation of compression fittings is performed in the following order:

- Begin assembly of the pipeline. Trim the pipes. To cut pipes from different materials, they select the appropriate device for work. Trimming is performed at right angles.

- Round off the edges. At the same time, they eliminate burrs and bumps. Defects and the presence of contaminants on the surface of the pipe, which is inserted into the body of the fitting, are not allowed.

- Remove the nut from the connecting part and put it on the pipe. After that, the crimp ring is installed. The thickened part of this part is turned towards the tail of the pipeline.

- They install part of the pipeline into the fitting, while the clamping ring advances all the way.

- Tighten and tighten the nut (first by hand, and then using a tool).

Compression fittings must be of the highest quality possible.

Compression fittings are very popular as they can be used to connect pipes made from a wide variety of materials: polyethylene, metal-plastic, copper, steel, polypropylene.

Advantages of using compression fittings for pipeline assembly:

- soldering is not required when connecting polyethylene pipes;

- allow you to disassemble the pipeline if necessary. For example, when carrying out repairs to replace a pipe section or to clean the pipeline if it is dirty;

- provide tightness of the system;

- this type of connection is resistant to vibrations and accidental mechanical stresses on the pipeline;

- can be used in places of high humidity;

- quite suitable for the installation of a pipeline designed for the transport of drinking water;

- a wide range of different configurations (couplings, bends, tees, adapters) and diameters (from 16 mm to 110 mm).

Features of the use of compression fittings

- Compression brass fittings for HDPE pipes are usually used for the installation of external pipelines. The use of compression fittings prevents slipping of the ends of the pipeline under tensile effects, under the influence of pressure and temperatures of the transported substances.

- Compression fittings for metal pipes are made of nickel-plated brass. It is recommended to check the tightness of the connection with the compression fitting of the plastic pipes several times a year and it is possible to tighten them additionally.

- Compression fittings for copper pipes are used when it is not possible to use open flame. Such fittings are made of metal-plastic, steel, copper and brass.

- Compression fittings for polypropylene pipes are made of polypropylene. If it is necessary to connect polypropylene pipes with pipes of another material, fittings with a plastic body and a female metal thread are used.

- Compression fittings for steel pipes are an alternative to welding pipe joints. But since the compression fittings are significantly inferior to welding in the strength of the joint, designed for a long lasting result (when using compression fittings when assembling heating systems, under the constant influence of the high operating temperature of the transported fluid, the fitting o-ring may lose its original operational properties and the joint will be depressurized) , it is recommended to use compression fittings as a temporary measure.

- Compression fittings for connection are used in the assembly of external pipelines operating under high pressure.

- A compression fitting for connecting a metal pipe is used during repair work on the pipeline. The compression fitting will play the role of an adapter. It makes no sense to connect metal pipes using compression fittings - it is better to use welding.

Compression brass fittings for copper pipes are in greater demand than copper or steel, as brass products are much cheaper and more ductile to process. To increase the strength characteristics, brass products are additionally coated with nickel.

Installation of compression fittings

Compression fittings consist of a body, a split ring and a union nut. The use of compression fittings for connecting pipes does not require the use of any special equipment. Only pipe cutters and a wrench are required. While tightening the nut with a key, the split ring is compressed on the pipe, which leads to a strong and tight connection between the pipe walls and the fitting.

The connection of polyethylene pipes with compression fittings is carried out similarly to the connection of metal-plastic pipes. But for polyethylene pipes, due to the softness of the material used for the manufacture of pipes, the use of compression fittings with a split ring is not acceptable, since the walls of the polyethylene pipe may well deform when compressed. In this case, the compression fitting consists of a housing, a union nut, and a rubber seal instead of a split ring.

Cost of compression fittings

The price of compression brass fittings, depending on the diameter of the product and the manufacturer, ranges from 46 rubles. up to 470 rub. (domestic producer); from 250 rubles / pcs. up to 2700 rubles / pcs. (foreign manufacturer);

The price of compression plastic fittings, depending on the diameter of the product, as well as on whether the product is monopolypropylene or combined, with metal inserts, ranges from 20 rubles / pc. up to 1600 rub / piece

Video

Look at the video instructions for connecting HDPE pipes with brass fittings:

During installation work When assembling the pipeline, it is recommended to use high quality fittings made of material similar to the material of which the pipes are made, and also taking into account the functional purpose of the mounted pipeline.