Local wastewater treatment plant Los. Local treatment facilities - what is it? Buildings for summer cottages

The main disadvantage of living in areas remote from cities is the lack of central communications, while homeowners have to independently solve the problems of water supply, heating, and sewage disposal. In the latter example, an ordinary cesspool or well for collecting wastewater does not solve environmental problems and can poison underground water sources, cause complaints from the sanitary service or neighbors - in this case, local treatment facilities for a private house (VOC) are installed.

Choosing the right option is not an easy task for a person with insufficient knowledge in this area, in addition to the fact that there are various cleaning technologies, there are various types and designs of treatment systems from a wide range of manufacturers on the market, and the choice of equipment also depends on the composition of the soil. A detailed study of information about VOCs will help to avoid mistakes when choosing an equipment option: bypass the marketing traps of unscrupulous manufacturers, choose the structure that is optimal for your site and living conditions, focusing on costs, or, with limited financial resources, make such a system with your own hands.

Fig. 1 Septic tanks on sites

Quite new in comparison with other regulations, construction rules SP 30.13330.2016 in clause 3.1.21, a definition of the concept of local treatment facilities is given - these are devices or engineering structures, the purpose of which is to treat the user's wastewater before sending it to the sewage system of the municipal economy or for circulating use for household needs.

Therefore, the abbreviation VOC for stand-alone treatment systems (AOC would be more accurate) is incorrect and is associated with the lack of a corresponding definition in state acts, even in the latest edition of 2016.

By VOCs manufacturers mean wastewater treatment systems without further recycling of water (irrigation does not belong to this category) and sending them to a centralized sewage system. Treated water enters the ground on the territory of the site, is discharged outside of it into gutters, or is used once for household purposes. Waste that cannot be cleaned is pumped out and transported outside the territory of the site by sewer trucks for further disposal.

All treatment facilities are located underground on the territory of the site, they can be divided into 2 main groups: mechanical cleaning or with the use of electrical pumping and compressor equipment.

Fig. 2

Fig. 2 Types of domestic waste water and the need for their treatment

There are two types of wastewater that enter the domestic sewage system:

- gray drains - contaminated water from kitchen sinks, washing machines and dishwashers, baths and showers;

- black drains - organic waste from sanitary facilities.

It is estimated that the percentage of gray water by volume will be 70%, and organic 30%.

The lack of a centralized sewerage system forces homeowners to look for a way out of a situation where the easiest option is to separate the effluent with the installation of an external toilet and dig a well for gray water. Often, such structures do not have a sealed bottom and the drains go directly into the ground, polluting the soil and shallow water layers; a sewer truck is ordered to clean the toilet and sewage pit. If in villages and houses of rural areas this practice is used everywhere, then next to large cities in cottage settlements such a violation sanitary standards may be noticed by neighbors or sanitary services. In the absence of a centralized water supply, it is highly likely that wastewater can penetrate into the well or the well of the owner of the cottage or his neighbors - this will lead to water contamination and possible poisoning, and the imposition of penalties. In addition, the lack of a sewerage system and the use of an outdoor toilet worsen the comfort of living and force homeowners to look for ways to independently treat sewage water.

Fig. 3 Tanks for septic tanks

Fig. 3 Tanks for septic tanks Cleaning methods

There are many methods of water purification using mechanical, physical, chemical, electrical and biological processes, but due to limited financial resources, most of them are not available to owners of country houses. If a large industrial enterprise or urban village can afford the design of local treatment facilities with wastewater treatment with chemicals using acids, alkalis and chlorine, and have large land plots for filtration fields, then the individual owner is limited in his capabilities.

There are only two sewage treatment methods available to him:

- Mechanical... It consists in the gradual settling of suspended fractions, after which the clarified liquid is drained into the soil.

- Biological... The same mechanical method, but with the process of decomposition of waste with the help of bacteria, due to which cleaning is accelerated, unpleasant odors disappear, the quality of the discharged water increases and it becomes possible to reuse it for domestic purposes.

Two types of bacteria are used for wastewater treatment:

- Anaerobic- work in an environment where oxygen is not required. This type of bacteria thrives in outdoor toilets and septic tanks.

- Aerobic - bacteria, for the vital activity of which oxygen is needed, in terms of efficiency of work significantly surpass their anaerobic competitors, are used in deep biological treatment plants for HBO, where oxygen is supplied to the container with their colony by a compressor for the development of bacteria.

Fig. 4 Filter fields

Fig. 4 Filter fields Types of treatment facilities

Before installing treatment facilities, their parameters are calculated based on the fact that 160-200 liters of wastewater per person per day. This is important for the proper operation of treatment devices - in containers of too small volume, the wastewater does not have time to settle and a very dirty liquid appears at the outlet, and if the volume of incoming wastewater is small compared to the capacity of the tanks, the owner incurred losses due to unjustified cost overruns.

Septic tanks

Septic tanks are local sewage treatment plants operating on the principle of mechanical cleaning, they are a series of interconnected containers (from 2 to 4) with a gradual decrease in the level of wastewater entering them. Septic tanks work on the principle of communicating vessels - the filling time of the first one is rather long due to its large capacity, during this time (at least 3 days) the drains have time to settle and the dirty sediment settles to the bottom. As soon as the tank is full and the liquid level reaches the top of the overflow pipe, it enters the next tank, where the process of settling and pouring is repeated again. From the last tank in the row, water is sent through a pipeline with holes that goes outside for air intake to the aeration field, which is an underground ditch filled with rubble.

Fig. 5 Septic tank from concrete wells

Fig. 5 Septic tank from concrete wells In septic tanks, oxygen-free fermentation and waste processing by anaerobic bacteria with the formation of methane gas take place, their efficiency is not too high, the degree of wastewater treatment does not exceed 70%, therefore, aeration fields are required for further additional treatment. The septic tank has the following disadvantages:

- During installation, tanks occupy a significant area underground, which is unprofitable for a small area, although some types have a more compact design in one housing (Uponor).

- Sludge sediment at the bottom of the tanks accumulates rather quickly, it has to be periodically pumped out with sewage trucks.

- Underground aeration fields occupy a certain area on the site, which is removed from economic circulation.

- With a frequency of 3-5 years, the filtering sand and gravel backfill of the fields has to be completely changed as a result of its siltation, excavation and fare for the delivery and removal of waste materials will require additional financial investments.

- If the site is located in clay soil, then the water will not go into the soil after cleaning in the aeration fields, but gradually accumulate underground and come to the surface - in this case, it will be necessary to take measures to remove it through ditches outside the site.

- At a high level of groundwater, contaminated effluents will be washed out of the filtering sand and gravel cushion - this will lead to soil contamination throughout the entire area and make it unsuitable for gardens and orchards.

- Odors are present, so it is recommended to place containers as far from home as possible.

Fig. 6 The device of a three-chamber polymer septic tank

Fig. 6 The device of a three-chamber polymer septic tank

- Of concrete rings... The design represents ordinary wells with a shallow depth of occurrence and a concrete bottom, a cover with a hole is installed on top of them, which is then closed with a polymer sand hatch.

- From polymers... Currently, septic tanks made of polymeric materials are in high demand, for their manufacture they use low-pressure polyethylene, polypropylene, fiberglass, to strengthen the body it is often reinforced with fiberglass or cast with stiffeners. During installation, polymer septic tanks can consist of several interconnected containers similar to a well system, or it is a single container, the internal space of which is divided by partitions into separate sections. The partitions have holes at different levels for overflowing water into adjacent chambers.

Fig. 7 The principle of operation of a septic tank with a biofilter

Fig. 7 The principle of operation of a septic tank with a biofilter Septic tanks with biofilter

A septic tank with a biofilter can achieve a high degree of wastewater treatment, a typical design is a tank divided into three sections, working according to the following principle:

- Initially, the effluent enters the primary settling tank, the volume of which is chosen so that the liquid remains in it for at least 3 days. As a result of mechanical separation, heavy silty sediments settle to the bottom of the tank, and light waste (feces, fat) form a crust on the surface, fragments of which, as a result of decomposition, settle to the bottom over time. At some distance from the surface in the partition dividing the containers, there are holes through which the settled water enters the next chamber.

- In the second sedimentation tank, the process of separating suspended fractions continues, in the chamber there is less water disturbance in comparison with the first section, where the stream coming out of the house muddies the water masses, there is no surface crust from light waste. As a result, the wastewater becomes even cleaner, the smallest suspended particles settle to the bottom, the treated wastewater flows through the upward branch pipe in the next wall of the compartment into the chamber with a biological filter.

- The last compartment contains a biofilter, which is a filtering bed made of expanded clay, crushed plastic or special cellular polymer structures, which contain a colony of aerobic bacteria. They recycle sewage, eating organic matter with the release of water, carbon dioxide and a certain amount of volatile gases, after which the purified water is drained into the soil, used for irrigation and other household needs.

In septic tanks with a biofilter, the degree of wastewater treatment is 20% higher; for the spread of bacterial colonies, liquid or bulk preparations (like dry yeast) are purchased in the commercial network, which, as life processes fade away, are periodically added to the biofilter.

Fig. 8 Design of a septic tank with bacterial cleaning

Fig. 8 Design of a septic tank with bacterial cleaning As can be seen from the principle of operation, it is not difficult to make a biological treatment system with your own hands in the presence of several chambers or wells, pouring expanded clay into the last settling tank and settling a colony of bacteria in it.

Fig. 9 Bacteria for septic tanks

Fig. 9 Bacteria for septic tanks  Fig. 10 Principle of work of UGBO

Fig. 10 Principle of work of UGBO - The water quality is higher; some models do not require the placement of filtration trenches.

- Since bacteria significantly speed up the cleaning process, a number of large-volume sedimentation tanks are not required and the entire septic tank can be placed in one tank - this factor is important for the small size of the site and allows you to save money when installing it.

- There are fewer or no odors.

- The sewer truck is called less frequently if bacteria cultures are added to the first sump.

- Compared to conventional septic tanks, the degree of wastewater treatment is much higher and averages 90%.

- Bacteria must be added to the biofilter once a month; in the absence of nutrition, their colonies die within 14 days and will have to be repopulated.

Fig. 10 Principle of work of UGBO

Fig. 10 Principle of work of UGBO Deep biological treatment stations (HBO)

Aerobic bacteria that eat organic matter need access to oxygen, with a sufficient amount of it, they multiply intensively and, accordingly, their performance in processing sewage waste significantly increases. In HBO installations, oxygen is delivered to bacteria by a compressor, which continuously supplies atmospheric air to their habitat.

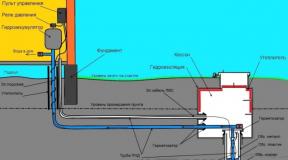

A standard LPG installation (Astra, Topas models) is a rectangular tank divided into several chambers (Fig. 10) that perform the following functions:

- Receiving chamber (A). Sewage water enters the receiving chamber, where it settles for a certain time, after which the liquid is directed to the next compartment through the air lift hose, that is, it is pushed out by air bubbles pumped by the compressor.

- Aeration tank (B). In this chamber, the main wastewater treatment takes place, it contains a colony of bacteria, and from the bottom through the aerator the air is forced by the compressor. As a result of the decomposition of organic matter, a suspended activated sludge is formed, containing processed products, a small part of undecomposed organic matter, and active bacteria, all this mixture gradually flows into the next compartment.

- Secondary settling tank (6). In the secondary sedimentation tank, the effluents are separated - the sludge settles to the bottom of the cone-shaped accumulator and gradually flows into the aeration tank B for additional cleaning, and the purified water is discharged outside.

- Sludge stabilizer (C). After some time, the Aeration tank is filled with products of organic waste processing (this is no longer active, but stabilized sludge), the automation monitors this situation, turns on the compression electric pump, which pumps the mass into the sump. There it is divided into fractions - the sludge settles to the bottom, and water flows by gravity into the receiving chamber A.

- The last chamber is designed to accommodate equipment; it contains the compressors of the aerial lift of the receiving chamber and the aerotank, and the automation unit.

Fig. 11 Design of the LPG station Topas

Fig. 11 Design of the LPG station Topas The deep biological treatment station has the following features:

- Provides the maximum degree of wastewater treatment up to 98%, which meets the sanitary requirements (SNIP).

- Due to the intensive processing process, it has the smallest dimensions of all types of VOC, during installation it takes up a small volume underground (the pit can be dug manually).

- Water can be safely used for irrigation without fear of any harmful substances getting on crops.

- Recycled sludge is a useful fertilizer that is used in the garden and vegetable garden, it can be scooped out on your own with buckets.

Fig. 12 Septic tank installation diagram

Fig. 12 Septic tank installation diagram - If there is no desire to free the container from silt, a sewer truck is called, which will be needed once or twice a year.

- Since bacteria cultures are actively multiplying, there is no need for new additions.

- Disadvantages include higher system costs and energy costs to ensure continuous operation of the compressors.

- The service life of the installation reaches 50 years, but the compressors will have to be changed after a certain time during continuous operation (although some models have a periodic switching mode).

- Biological treatment plants require periodic maintenance by specialists.

Fig. 13 Storage septic tanks

Fig. 13 Storage septic tanks Cesspool (drain) pit

It does not always make sense to use local treatment facilities on a site for a house for arranging a sewage system with periodic residence, a short time spent in a home (for example, a country cottage) - in these situations, a simple drive is enough. It can be a cesspool with an open bottom, which is unacceptable from the point of view of ecology, or a closed container into which sewage water is constantly drained. If the area has a high level of groundwater or clay soil, then it is unlikely that it will be possible to make an ordinary cesspool - the drains will rise to the surface when it is filled or washed out throughout the area - you will have to install a closed container of large volume. Various underground models can be purchased on the market, with the following advantages:

- The storage tank is made of durable plastic with a hermetically sealed lid to prevent unpleasant odors in the area.

- The device does not require maintenance, water does not need to be purified and then drained to the ground, damaging the environment and soil in its area, risking contaminating shallow underground water layers.

- The cost of the storage tank is much lower in comparison with treatment facilities.

Of the minuses, it should be noted that periodic pumping out of wastewater with the help of sewers will be required, for which you will have to pay each time.

Fig. 14 Scheme of VOC operation for storm water treatment

Fig. 14 Scheme of VOC operation for storm water treatment Stormwater treatment

Sometimes on an individual site you have to wash and repair a car, and if a private car wash or workshop is organized, then you have to solve the problem of cleaning rainwater containing petroleum products. Sending them to the sewer system is not a good option - in the sump they will collect on the surface and interfere with the work of bacteria. Therefore, it is easier to mount the local stormwater treatment facilities separately, directing water into them through surface storm water inlets, having previously organized a small slope of the polluted area.

Industrial treatment facilities consist of: a distribution well, and a gas-oil separator; at the outlet, a technological well is installed for sampling. For household cleaning, it is unprofitable to build such a system; for a filter, you can use a home-made system from an airtight container filled with sand, expanded clay, foam crumbs, effectively use fibrous and porous materials (foam rubber, rags). Storm runoffs passed through the filter are then drained into the ground or sent outside the site, the filtering materials are periodically changed as they become dirty.

Fig. 15 Installation of surface drain

Fig. 15 Installation of surface drain Modern sewage treatment systems use biological treatment with aerobic bacteria that destroy organic compounds. In contrast to conventional sedimentation tanks, the cleaning efficiency increases significantly, reaching 98%, and the water can be used in the domestic sphere. Septic tanks with biofilters are the best option from the point of view of financial costs and efficiency: for simple sedimentation tanks, aeration fields are required and the cleaning quality is low, and deep biological treatment plants, in addition to a high initial cost, require constant power supply and maintenance.

Septic tank selection

Septic tanks from reinforced concrete rings

Overview of septic tanks

Sewerage treatment facilities are necessary for the rational drainage of waste, domestic and storm water. If these structures do not function properly, the environment can be seriously damaged. That is why the work of sewage systems is regulated and monitored at the legislative level.

The principle of operation of the sewer structure

The sewerage system can include a variety of devices. But, despite this, waste treatment is carried out according to a certain algorithm.

First step

At the first stage, waste water is mechanically treated. The retention of large contaminants, which are of mineral and organic origin, is carried out by grates and sieves. With the help of grit traps, smaller particles are filtered - broken glass, sand and slag. A more thorough cleaning is carried out by the membrane device. Suspended substances are separated in the sump. This removes mineral contamination.

Second phase

In the next step, biological agents are used for cleaning. Organic compounds decompose under the influence of particularly active bacteria. The liquid is passed through a biofilter. The result is sludge and gaseous compounds.

Stage three

At the final stage of wastewater disinfection, additional chemical compounds are used. The resulting liquid can already be used for technical purposes.

Types of sewer systems

Sewerage treatment facilities are designed before the start of the construction works... It is important to choose the right sewer design that will be able to solve the tasks for waste disposal and have a sufficient level of productivity. Today, wastewater treatment can be performed using the following devices:

- local cleaning devices;

- individual stand-alone structures;

- block systems and modules.

Local cleaning systems

Local treatment facilities are such structures with the help of which the cleaning and collection of waste is carried out at objects of various sizes. They can be for household or industrial purposes and are the basis.

In classical sewage treatment devices, the flow rate of wastewater decreases with distance from the discharge point. There is a gradual settling of solid particles at the bottom. The remaining sewage is removed by post-treatment systems. For classical treatment facilities, sufficiently large containers are needed in which the waste is settled. This requirement is difficult to implement in individual buildings.

With the help of local treatment systems, wastewater is collected and treated in private houses or small villages where there is no central sewage system. Let's consider the most common local constructs.

The use of septic tanks

Septic tanks are often used to equip an autonomous sewage system in country houses. They usually look like plastic containers. Plastic has the necessary performance characteristics:

- it weighs little - the tanks are easy to transport and install;

- the material can withstand the effects of an aggressive environment;

- does not rust;

- has sufficient strength.

Each tank contains a different number of sections that perform specific functions. Some act as a settling tank, while in others, wastewater is purified using biologically active microorganisms. Still others are used for filtering.

Septic tanks are widely used in the construction of private treatment plants. They are convenient to operate. They have a long service life. The sewer system device can be completely autonomous. In order to increase the level of sewage treatment, the design is equipped with additional elements - fields that filter and aerate.

The simplest and most effective septic tank

Aerotanks

These purification devices are an integral part of large sewage systems that carry out wastewater treatment from industrial enterprises. They look like huge tanks. In tanks, water and activated sludge are mixed. Oxygen is used to accelerate the reaction. Sometimes aeration tanks are used in the construction of autonomous sewage systems in a private house. In this case, they have a small volume. Usually they are mounted in septic tanks. Aerotanks may include special traps. They remove grease and oil products from drains.

Using biological filters

When installing sewage systems, biological filters are also used. Most often they are used as embedded structures. Biofilters are part of local treatment facilities. In these devices, wastewater is treated with the help of special bacteria. Microorganisms contribute to the accelerated decomposition of sewage. At the outlet, a liquid is formed that does not harm the natural environment and can merge into the soil.

Storm sewage systems

In local treatment facilities, harmful impurities, inorganic and organic waste are removed from drains. Subsequently, the purified liquid is used to irrigate the fields. But in order to collect, transport and purify melt and rain water, storm water treatment plants are also used. Conventional sewer structures can not cope with this task.

Rainwater treatment plants should ensure the safety of the foundation, pavement and lawns surrounding the main structure.

They include pipes, gutters and storm water inlets. Through them, the excess water is transported to a common collector.

The system is placed below the level of soil freezing. The design contains filters to trap sand and other fine particles. Purified fluid must enter the collector.

Finer wastewater treatment is carried out using additional devices: a sorption unit and a filter for removing petroleum products. At the final stage, purified water is discharged into water bodies or used to water the garden. It should be borne in mind that in this sewer system it is necessary to periodically replace the filter elements.

Autonomous sewer facilities

The device of autonomous systems for sewage is very similar to the design of local treatment facilities. But they have their own distinctive features. This class of sewer systems includes septic tanks and wastewater collection tanks, in which sewage is accumulated at the initial stage, and only then they are filtered.

The use of block and modular designs

Block and modular sewage systems carry out deep sewage treatment. They are more often used in industrial and industrial fields. Using such devices, the following tasks are solved:

- high level of wastewater treatment is provided;

- reduced sludge content in the purified liquid;

- the environment is protected from harmful substances;

- the opportunity to reuse water.

Such systems have enhanced performance. They can be used to serve entire areas. Used in wide temperature ranges.

Sewer Design Selection

To choose the right cleaning system, you need to consider a number of factors:

- the total amount of daily fluid intake;

- preferred type of sewer structure;

- mode of use of the sewer structure;

- location of the object.

Some devices may work offline. The functioning of others requires electricity or other forms of energy. Certain systems cannot be used in close proximity to groundwater.

When arranging a treatment system should be guided by existing sanitary standards. If for disposal of waste it is necessary to use a scavenger machine, it is necessary to provide for the possibility of free access to the waste storage site.

Features of the design work

When designing sewage treatment plants, it is necessary to provide for the emergence of various situations that may subsequently affect the operational characteristics of the system. It is also necessary to take into account the existing legislative framework.

Its basis is security functions to protect the natural environment. The cleaning system must be in a sanitary-protected area. In the design process, you should pay attention to the following indicators:

- dimensions and volume of the sewer structure;

- optimal view of the device;

- groundwater location;

- soil freezing level;

- system performance;

- used cleaning method;

- optimization of the installation of the sewer device.

So that subsequently there is no conflict with the sanitary permitting services, before the construction of the sewage system, it is necessary to prepare a number of documents:

- agreement on ownership or lease of land;

- location scheme of the place where it is supposed to place the treatment plant;

- compliance with existing sanitary standards;

- technical conditions for the use of water resources;

- data on the volume of consumed and utilized water;

- general outline of the project;

- description of the filtration and waste water disposal system.

Permission of the sanitary and epidemiological station must be present. It should be remembered that in case of violation of sanitary standards for the facility, the owner can be held administratively liable.

Video: Wastewater Treatment Plant

For a comfortable life in a private house with a kitchen, several bathrooms and showers, a reliable system for collecting, filtering and processing wastes resulting from human activities, which would not require frequent pumping and time-consuming frequent maintenance, is necessary. If the house does not have the ability to connect to the central sewage system, then the outlet in this case is the local treatment plant. In this article, we will talk about the principle of operation of an autonomous sewage system in a private house and about the advantages and disadvantages of such a system.

The sewer system for a private house can be divided into three types:

- septic tank;

- local treatment facilities.

Cesspool This is the easiest type of sewer to install and maintain. It involves the discharge of wastewater into a sealed container in which they are stored and from which they are periodically pumped out with a sewage machine. For the construction of a cesspool, as a rule, reinforced concrete rings buried in the ground are used and access to the pit is organized by installing a hatch. The disadvantages of such a system are the need for regular cleaning of the container, as well as the appearance of an unpleasant odor, which cannot be eliminated even by disinfection.

It is a large capacity consisting of several cameras communicating with each other. In the first chamber, the waste passes the stage of primary mechanical cleaning - settling, in which the solid parts settle to the bottom, and the water purified from these parts by gravity passes into the second chamber. Biological purification takes place here - anaerobic bacteria process suspended organics into sludge without oxygen, further purifying the water.

Since the process of water purification without oxygen is not very effective, the water outlet has a degree of purification of about 80%. Even for technical needs, such water is unsuitable. For further cleaning, the septic tank involves the use of or aeration fields.

The advantages of such a sewage system are autonomy and independence. There is no need to supply electricity to the septic tank, and human intervention is limited to cleaning the system depending on the intensity of use. But when filtering waste in such systems, methane is released, for the removal of which ventilation is installed with a conclusion not lower than the level of the roofs of houses.

The third type is local treatment plant (VOC or local treatment facilities) Such a plant purifies waste water with a purification degree of up to 98% with the highest quality. Let's talk in more detail about how autonomous sewage works.

The principle of operation of autonomous sewage

Local treatment facilities are a complex of tanks where the effluents pass through several degrees of treatment. A fundamentally autonomous sewage system contains the functions of a septic tank, in which the mechanical treatment of wastewater takes place, and the function of aerobic treatment, where aerobic bacteria efficiently process fine suspension into sludge, maximally clarifying the effluent. Let us consider in detail the principle of operation of VOCs.

At the first stage, drains from the house by enter the first chamber of an autonomous sewer, called the reception. The volume of such a capacity is on average 3 cubic meters. Here, as in the septic tank, settling of large particles takes place, as well as the separation of fat particles using special grease traps.

At the next stage, gravity water enters the next chamber, with a volume equal to half the first chamber. This capacity is called aeration tank, since there is a saturation of wastewater with oxygen. This happens with the help of an air compressor, which pumps oxygen-saturated air through the hoses from below into the chamber, while mixing due to the many bubbles rising up.

Colonies of bacteria are settled in the same chamber, which gradually transform the fine suspension into activated sludge, eating it and turning it into sufficiently large flakes, which due to their weight can settle to the bottom. The high activity of such bacteria is due to the constant flow of oxygen into the aeration tank.

All this mixture of liquid and activated sludge mixed in it is gradually moved by gravity to the next tank - a secondary sump, in which the sludge settles on a special cone-shaped trap, and then is pumped back to the aeration tank. The purified water, separated from the sludge, enters the next stage of treatment.

When the maximum amount of spent sludge is accumulated in the aeration tank, the system automatically pumps it into a special sump, from which it is removed and used for household needs.

After the secondary sump, already sufficiently purified water enters the next tank, coming into contact with a chlorine-containing preparation. Here, the final disinfection of effluents and their after-treatment takes place. At this stage, water is purified up to 98%, starting to comply with sanitary standards.

Removal of purified water from an autonomous sewer can occur in several ways:

- Having poured into a special storage well, from where the water will be pumped out by a pump or used for household needs. This method is used with a high level of groundwater occurrence or with the need for industrial water for irrigation of the garden.

- Overflow in, where the water will go into the ground. This method is possible if there is sandy or loamy soil on the site. A plus here is the lack of need for pumping effluents.

- Organization This method is also used with a low level of groundwater. The advantage of aeration fields is additional soil fertilization at the place of discharge of treated water.

Due to the intensive processing process, autonomous sewage has the smallest dimensions compared to conventional septic tanks, which indicates the convenience of its installation on the site. Purified water can be used for irrigation on the site, without fear of any harmful substances entering the soil, and recycled sludge is a useful fertilizer that is used in the garden and vegetable garden, it can be scooped out on its own with buckets.

VOC is a closed installation in which cleaning is carried out inside the chambers and does not require direct human intervention. The filter elements and the grease trap are cleaned about once every 6 months, and the preventive visual inspection of the chambers is carried out once a month. Pump replacement may be necessary after several years of operation.

The main minus of the station is the need for uninterrupted power supply. With a prolonged absence of electricity, some filter elements may become unusable.

How to choose an autonomous sewer for the house

For a rational choice of the type of local treatment facilities, a number of factors must be taken into account: the condition and composition of the soil into which the sewage system will be mounted, groundwater, the shape and size of the site, the number of people living in the house, is the dwelling seasonal or permanent.

The choice between a septic tank and VOC will be reasonable if you calculate the most common situations:

- Budget. If it is limited, then a septic tank should be installed. It is cheaper and less money will be required for its maintenance.

- Groundwater. If their level in the area is high, then installation of a septic tank becomes impossible, since there will be no possibility of installing additional treatment facilities (equipment of filtration wells and pits in this case will be costly and require a large amount of work). The advantage of VOCs is obvious - the outlet water will not be harmful to the environment.

- Power supply. With frequent blackouts and power outages, the installation of an autonomous sewage system is not recommended. When the system stops, the filters may fail and bacteria may die. Refueling and fixing such a system is an expensive procedure. You can install a backup power source, but it is preferable in this case to use a septic tank based sewage system.

- Seasonal accommodation. If the owners live in the house only part of the year, then the choice falls in favor of the septic tank. Long interruptions in work can adversely affect the operation of local treatment facilities, and the operation of electrical autonomous sewage systems idle will result in unnecessary financial costs.

Thus, autonomous sewage is the most advanced way of wastewater treatment in a private house. The only negative is the high cost of equipment. It is also worth remembering that for the operation of VOCs, electricity is necessary, and when it is turned off, the device will work like a septic tank. Therefore, the final choice, taking into account all the pros and cons, remains with the owner of the house.

Sewage treatment plants are very important installations for the functioning of the water drainage system. The situation is that wastewater from the household sphere can harm the environment. It is for this reason that the legislation regulates the functioning of sewers and establishes certain norms for mechanisms. In our article we will get acquainted with the types of filtration facilities and the requirements for SPZ (sanitary protection zone).

Ignoring the fact that the sewer installation has a wide variety of types and models, it is possible to choose the optimal type of construction according to this general principle of operation:

- The first stage is a mechanical cleaning process. This is the type that can occur in the sedimentation, filtration and grease collection of sewer flows. After finishing work, a so-called clarified liquid is obtained.

- In the second stage processing by biological means. The liquid is poured into a biofilter, where organic matter is processed. The result of work is sludge and the formation of gases.

- Last process - This is a disinfection of the stream. It is worth noting that it is carried out using chemicals.

Attention! At the end of all processes, technical water is obtained, which can be reused.

Construction choice

The design of sewage treatment plants is carried out before the start of construction work at home. For this reason, the very important action is the optimal choice of a sewage treatment plant. For the implementation of tasks it is necessary to choose the type and the appropriate level of performance. To date, there are such varieties of structures:

- Devices for local cleaning;

- Individual or local devices;

- Systems with blocks and modules.

Let's look at each type of them in more detail.

VOC: Local - treatment facilities

A local treatment plant is all devices in a building that receive all types of sewer systems. Designs differ in scale and are precisely for this reason that they can serve objects of various sizes. Let's look at the different division of VOCs into subgroups. So, according to the purpose, there are such types:

- Household type;

- Industrial.

Attention! Local devices are suitable for all systems except the central city sewage system.

Individual or autonomous structures

Very similar to VOCs, but it is worth considering that this type of structure has its own distinctive features. They are fixed in the internal structure of the tank, technical indicators and the principle of functioning of the mechanism. This group of structures includes all types of septic tanks, storage tanks, which are initially involved in the accumulation of effluents, and then filter them.

Attention! It is worth noting that devices of an individual type have a simpler design than VOCs.

Block and modular treatment facilities

Sewage treatment plants with a modular and block system are deep cleaning devices that are used in the activities of the industrial, household and industrial sectors. This type of installation performs the following tasks:

- Ensuring a high level of sewage treatment;

- Minimizing sludge formation;

- High-quality deep cleaning;

- Silent operation and environmental protection from drains;

- Providing opportunities to reuse water.

It is worth noting that the performance of such devices reaches from 10 to 10 thousand cubic meters per day. This indicator is capable of processing the effluents of entire villages. The advantage of the systems is the ability to function even in a temperature climate of -55 degrees. Blocks and modules organize the type of work, which is based on stepwise cleaning.

Choose the type of structure

To produce the correct and optimal choice cleaning systems, you should start from the following parameters:

- The volume of water consumption per day. Its value depends on the number of residents and household appliances.

- Regular use of the sewer system;

- Characteristics of climate and soil;

- The level of freezing of the earth.

Design Features

When performing the design of sewage treatment plants, it is necessary to calculate all situations that in the future may affect the operation of the device. First of all, one must not forget the different legislative framework, which is based on the protective function of the environment. So, to comply with the sanitary protection zone, the following indicators should be taken into account:

- Calculation of size and volume;

- Selection of a place, according to the requirements, which has a sanitary protection zone (SPZ);

- Selection of the optimal device;

- Features of the soil and climatic conditions;

- Accuracy of performance calculation;

- Rational selection of a cleaning method;

- Correct option installation work for installation.

Attention! The sanitary protection zone (SPZ) is a very important norm in relation to the installation location. If the requirement is not fulfilled, then environmental contamination is possible, and as a result, an environmental disaster will occur.

SPZ is not the only requirement. In addition to this, you should arrange the paperwork so that later there will be no problems with the establishment of the sanitary protection area. So, the folder should contain the following documents:

- The agreement, which indicates the lease of the land;

- A schematic map showing the place where the construction of sewage treatment plants can be carried out and the sanitary protection zone (SPZ) fully complies with the standards.

- Technical characteristics of the use of water resources;

- The difference between consumption and disposal of water;

- A document that contains information about the general points of the project;

- Scheme of runoff filtration facilities;

- Description of the disposal and use of waste streams.

Attention! Permission sanitary epidemiological station is an important factor. Remember, if the sanitary protection zone (SPZ) is violated, then you may incur administrative responsibility.

SNiP regulation

This type of installation at each stage of installation is regulated by the legislation of the Russian Federation. It is for this reason that it is very important to carry out work in accordance with all norms and requirements in order to avoid a large number of problems in the future. If we take SNiP, then it contains building rules and sanitary protection zones (SPZ). Let's find out the basic concepts:

- Items about “Sewers. Outdoor networks and facilities, they are recorded in SNiP 2.04.03-85;

- Clause 4.5, SanPiN 2.2.1, the rules “Sanitary protection zone and protective sanitation of enterprise classifications” are spelled out. It is worth noting that the SPZ monitors the protection of nature from various kinds pollution. For example, the zone should be located to the house at a distance of 50 to 100 meters.

- FSUE NII VODGEO describes the norms for various calculations when creating a project.

If you adhere to all sanitary protection standards, this will guarantee a high-quality installation work and will protect you from various problems with regulatory organizations.

GK LOCAS will perform a full range of works on installing sewage treatment plants, from design to turnkey installation.

Local treatment facilities are used in Russia relatively recently, but have already become the standard for environmental friendliness and efficiency. The level of wastewater treatment by microbiological stations reaches 95%. Sometimes even industrial wastewater treatment plants do not demonstrate such results.

The main functional component of any local sewage treatment plants are microbiological decomposition chambers. The decomposition of organic sewage occurs both with the access of air (aerobic bacteria), and without it (anaerobic bacteria). So that the former can exist normally, air is constantly pumped into the liquid. The latter live in the water column on their own.

Mechanical precipitation is also used, but not as the only way to reduce the general toxicity of sewage (or at least to reduce its volume), but as a concomitant phase, which is the final in the technological sequence of turning household sewage into harmless fertilizer. In this case, the compaction of silt does not occur due to gravity, but as a result of its complete decomposition.

VOS sewerage application conditions

Local sewage treatment systems are used in all climatic conditions. In cold regions, they are installed with additional insulation, which provide foamed polymer slabs, in warm - without it. In any case, heating is not required - the temperature of the sewage discharged from the house is sufficient. To maintain this temperature without loss, waste pipes must be placed in special thermal insulation.

The purchase of local sewage treatment systems, as well as their subsequent installation, is much cheaper than the design and installation of centralized settlement facilities for wastewater treatment. And this does not include the cost of operation and maintenance! That is why microbiological treatment plants are found today even in those settlements where there is the opportunity to connect to central communications.

Autonomous sewage treatment plants maintain their effectiveness over the entire life cycle, while the centralized sewage system gradually deteriorates, regularly reminding it of accidents by blockages in pipelines.

The main advantage of individual treatment facilities in cottage villages over centralized treatment plants is that there is no need to lay a sewer network throughout the village and to allocate land for settlement treatment plants with a large sanitary zone. This significantly reduces capital costs in the construction of the infrastructure of the cottage village. This means that it gives the investor a great advantage over competitors. OS LokOS is the best choice for both an individual cottage and a village.