A set of sealants for assembling cast iron sections of boilers. Repair of cast iron boilers. Replacement of heat exchanger sections. When is it necessary to replace a section of a cast iron boiler, Replacing sections of a heat exchanger

The company "CLIMATIC" provides services for the maintenance and repair of cast iron boilers KChM, Universal as well as cast iron boilers of foreign manufacturers - VIESSMANN, BUDERUS, PROTHERM, DAKON, VIADRUS, MORA and others. Deep knowledge and vast experience of our employees working on this equipment, the availability of professional tools, original consumables and spare parts allow us to be confident in the quality of work.

Replacement of sections in boilers KChM, Universal-RT

Replacement of heat exchanger sections of boilers VIESSMANN, BUDERUS, PROTHERM, DAKON, MORA, etc.

Repair of boilers Universal-6M, Universal-5M.

|

Cast iron boilers Universal-6M, Universal-5M are repaired in the same way as all sectional cast iron boilers. The repair of boilers of this type is complicated by the presence of heavy lining of refractory bricks and the massiveness of the boiler sections. Our company has extensive experience in the repair of boilers of this type. The replacement of sections in the Universal-6M boilers will be carried out by our specialists in the shortest possible time and at a high professional level. The availability of specialized assembly tools and original spare parts allows us to guarantee the high quality of repair work for Universal-6M boilers. |

When is it necessary to replace the section of the cast iron boiler?

Over time, the heat exchanger wears out, corrosion and scale do their job. However, its complete replacement of the heat exchanger is impractical, since usually individual sections fail, then the cast-iron section of the boiler needs to be replaced, in which a crack appears. Repair of the section does not give the desired effect - due to constant temperature expansion of cast iron, the welded seam collapses after a short time.

In some cases, a crack can only be detected during boiler diagnostics. Therefore, for a certain time the technique is used with the presence of a crack, which increases the destruction. Moreover, if you do not want the boiler to completely fail, then the problem must be solved immediately after detection.

The cost of replacing a section of a cast iron boiler

The cost of replacing a section of a cast iron boiler depends on the model of your equipment, its capacity, and the complexity of the work performed. The final price can be determined only after a visual inspection of the place of work by the master.

Is it possible to independently replace a section of a cast iron boiler?

Some equipment owners are trying to replace the section of the cast-iron boiler on their own. However, here they face a number of problems:

- How to disconnect a damaged section of a cast iron boiler from a package of sections.

- How to seal the joints between the installed sections.

- How not to damage adjacent sections and the package of sections as a whole.

- How to do the whole range of work without a special tool.

- How correctly, without distortions and overvoltage of the entire heat exchanger, pull off the package of sections.

Self-repair of a cast-iron sectional heat exchanger is quite problematic - as a rule, there is no necessary tool, there are no skills for such work. Despite the seeming simplicity of the process, there are frequent cases of damage to a new section due to improper installation, as well as damage to neighboring, previously whole sections. As a result, self-repair results in even higher costs than the involvement of a specialized installation organization.

Fast, high quality, reliable. With a guarantee!

We guarantee prompt and high-quality performance of the entire cycle of work on the replacement of sections on your boiler. The vast experience in carrying out belt work on cast iron boilers of various capacities allows us to assert that the work will be performed efficiently and on time! The assembly team will independently deliver all the necessary spare parts and consumables to your site - and this will not affect the cost of work, no additional payment for delivery.

After assembly and pressure testing of the heat exchanger, if no heavy lining device is required (Universal-6M boilers and similar), the boiler will be ready for normal operation. For the work performed, a guarantee from 6 to 12 months is provided, depending on the manufacturer of the boiler.

Despite the relative reliability, experts note several of the most common causes of heating unit failures. The most common is a coolant leak caused by a crack in one of the heat exchanger sections. The repair consists in the complete replacement of the deformed section.

Reasons for the appearance of a crack:

- critical overheating due to accumulation of deposits inside the section;

- large temperature difference in supply and return, causing thermal shock;

- incorrect burner settings;

- manufacturing defects.

The owner of the cast-iron boiler should be alerted by the regular drop in pressure in the system. These signs can also indicate the formation of microcracks on the walls of the boiler.

Repair of cast iron boilers

Often, restoration work requires preliminary disconnection of the equipment from the general heating system. This requires:

- close the valves;

- drain and pump out water;

- disconnect the flanges;

- remove fittings and headset;

- remove the cover (if any).

Work on cleaning or replacing sections begins with hanging the cast iron boiler. The further process of diagnostics, cleaning, replacement, pressure testing, flushing should be carried out using special devices by experienced craftsmen.

Only specialists will be able to properly re-install the removed equipment, align new sections by plumb lines and levels, adjust the operation of burners and other important components. Incorrect assembly and adjustment of the heating system can create an emergency.

Entrust your business to professionals

We provide repair services for cast iron boilers of any manufacturer. For this, our company has all the necessary conditions:

- experienced qualified certified personnel;

- certification and permits from supervisory authorities;

- necessary tools, fixtures and equipment;

- spare parts and consumables for the repair of heating boilers.

All together this makes it possible to perform work quickly, efficiently and inexpensively. Immediately after placing an order, we go to the address indicated in it and return the cast iron boiler to working condition.

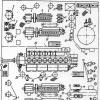

A cast iron sectional boiler of any type is assembled from separate sections. By designation and configuration, there can be frontal, middle and rear sections of cast iron boilers. The assembly is carried out on threadless nipples (sections of the steel boiler are assembled by welding). When installing sectional boilers and auxiliary equipment, a significant amount of work falls on the horizontal and vertical transportation of individual parts, packages, units or assemblies. These works are performed with rigging means, of which jib cranes should be recommended first of all. If they are absent, jacks, winches, hoists, etc. can be used. Boiler sections can be assembled in packages directly on the walls of the combustion chamber lining, as indicated in Ch. 2, packages can also be prepared outside the facility and, after testing, delivered to it (Fig. 2) and installed in the design position with the help of rigging.

In all cases, it is necessary to strive for a batch method of installing sectional boilers. However, in practice, the installation of boilers from separate sections still takes place, therefore, the technology for their installation is described below.

After acceptance of the construction part, the walls of the red brick firebox are laid on the concrete foundation to the level of the grate beams and the grate beams are installed; then the walls of the furnace are laid out of refractory bricks to the mark of the bottom of the boiler sections. Simultaneously with the walls of the furnace, the outer wall of the gas duct is laid out to a height somewhat less than the height of the wall of the furnace. The red brick is laid with the bandaging of the seams on clay mortar, and the refractory brick is laid on the mortar of refractory clay mixed with fireclay powder. The hog is laid out of red brick on clay mortar. At the level of the end of the masonry, the walls of the furnace are arranged with a scaffold for the convenience of installing the boiler.

During the production of these works, the locksmiths prepare the boiler for installation: they clean the sections from the molding earth, wash the nipples and nipple nests with kerosene, having previously cleaned them from rust, and transport the sections to the boiler room as close as possible to the place of assembly. At the same time, rigging means for lifting the sections are prepared and installed.

Before installing each section, nipples lubricated with graphite mixed with natural drying oil are inserted into its nipple holes on one side with light hammer blows through a wooden block. Then the sections are set in turn in the design position, and each subsequent section is put on the nipples of the previous section with nipple holes. The outer surface of the nipples is conical, which eliminates the possibility of slipping of the nipple in the nipple seat and creates a metal-on-metal seal that prevents water seepage. However, in practice, the nipple is lubricated with graphite paste and a cord asbestos cord impregnated with red lead or graphite mixed with natural drying oil is wound around it. Thin cord asbestos harness creates a more reliable seal.

When assembling the boiler sections, special attention should be paid to their stability. The stability of the gradually assembled package can be achieved with the help of time stops. In this case, the rear sections, from which the installation of the boiler always begins, are fastened with a bar and raised to the base. The rear sections, installed in the design position, are fixed with temporary stops to the floor or wall, depending on local conditions. After that, the individual sections of the right and left packages are lifted by a lifting mechanism in turn and connected to each other on the nipples. Thus, both packages are collected in parallel.

Recently, the mounting device shown in Fig. 3 has been used; assembly with its help simplifies installation and makes it safer, since the stability is more reliable. The mounting device consists of racks 1 and 2, crossbar 3 and cantilever support 4. When assembling the device, first, the middle rack 1 is installed on the bottom of the ash pan, then the crossbar 3 is put on it and bolted at a height slightly exceeding the height of the boiler, after which it is pushed onto the crossbar end posts 2 and are also bolted. Next, a cantilever support is fixed on the middle pillar 4. The device is assembled at the installation site of the first middle sections of the rear of the boiler, which, after the completion of the assembly of the device, are set to the design position, verified and secured with screw grips 5. Then the extreme rear sections are installed and further installation is carried out similarly to the above higher. The device shown in Fig. 3 can be used to assemble any type of sectional boilers.

In detail: do-it-yourself repair of cast-iron heating boilers from a real master for the site site.

The technology for eliminating damage to the sections of a cast-iron heat exchanger is dictated by its design. Repair problem is being solved replacement of the boiler section ... The heat exchanger is a prefabricated structure. Elements are assembled into a single unit by means of accessories (conical connecting nipples). Violation of the integrity of one of the sections leads to the failure of the entire device. What are the causes of destructive deformations and heat exchanger leakage?

A bit of theory - what phenomena cause the destruction of the heat exchanger?

Cast iron heating devices are more durable than steel counterparts. Cast iron corrodes less in aquatic environments. therefore gas boilers from this material almost do not rust. However, cast iron (in contrast to steel) is more sensitive to local temperature peaks. To preserve physical properties structures negatively affects the effect of cold water on the heated metal.

The listed situations arise when the service rules are violated:

Clogging of the device leads to overheating of individual small sections of the cast-iron surface.

Make-up for working a gas boiler cold coolant creates a temperature contrast.

Incorrect adjustment of the burner violates the overall thermal regime.

These phenomena lead to the appearance of the so-called. "Heat shock" of the metal. As a result, one or more elements are deformed relative to others or simply burst.

A common breakdown during operation is a leaking device. There may be several reasons for this: a microcrack in the body of the structure, drying of the sealing sealant. Then the need arises replacement of the cast iron boiler section ... It is better to invite specialists from a service organization for repairs. Such companies carry out repairs regularly. They have a professional tool for assembling the devices.

the repair is carried out in stages. It begins with the diagnosis of the body of the structure and ends with testing and commissioning. Intermediate operations:

Dismantling of the casing and sectional disassembly;

Replacing the boiler section and screed of all elements;

Connecting the device to the heating system;

For diagnostics, the device is stopped. After cooling, dismantle the casing and the thermal insulation layer. The nature of the damage and the number of compartments to be replaced are determined visually. If the leak is caused by a microcrack, and the location of the defect cannot be immediately detected, the water pressure is increased to 2 kg and left for a day.

Splitting into sections is accurately performed mechanically.

In this case, they try to hit only the defective element.

Followed by replacement of sections of a cast iron boiler ... Neighboring damaged elements are inspected for timely detection of debris. They are washed or replaced with new ones. Sometimes the craftsmen decide to assemble the unit and then rinse it with water and chemical reagents.

Before screed, all contact surfaces of the elements with each other are thoroughly cleaned. The coolant path is sealed with new nipples and lubricated with a special paste. After replacement of boiler section the smoke path is also sealed. To do this, cover the joints with mastic or pull them together with cords.

The screed is performed using a special tool.

It is very important to avoid skewing and to connect the sections precisely.

When replacing several elements, they are added to the assembled structure strictly one at a time.

In the next step, the device is connected to the system and needs to be pressurized. For this operation, it is supplied with the maximum pressure allowed by the manufacturer. For each model, this parameter is indicated in the passport.

Repair of a cast iron heat exchanger required without an obvious violation of integrity. When the pressure of the coolant regularly drops in the device and it often has to be replenished with water. The reason for this behavior of the boiler lies in the appearance of microcracks in the furnace. At high temperatures, the liquid has time to evaporate and is removed with flue gases. Unstable work is a good reason to contact the service department.

The KLIMATIK company provides services for the maintenance and repair of cast iron boilers KChM, Universal as well as cast iron boilers of foreign manufacturers - VIESSMANN, BUDERUS, PROTHERM, DAKON, VIADRUS, MORA and others. Deep knowledge and vast experience of our employees working on this equipment, the availability of professional tools, original consumables and spare parts allow us to be confident in the quality of work.

Replacement of sections in boilers KChM, Universal-RT

Replacement of heat exchanger sections of boilers VIESSMANN, BUDERUS, PROTHERM, DAKON, MORA, etc.

Repair of boilers Universal-6M, Universal-5M.

When is it necessary to replace the section of the cast iron boiler?

Over time, the heat exchanger wears out, corrosion and scale do their job. However, its complete replacement of the heat exchanger is impractical, since individual sections usually fail, then the cast-iron section of the boiler, in which a crack appears, needs to be replaced. Repair of the section does not give the desired effect - due to constant temperature expansion of cast iron, the welded seam collapses after a short time.

In some cases, a crack can only be detected during boiler diagnostics. Therefore, for a certain time the technique is used with the presence of a crack, which increases the destruction. Moreover, if you do not want the boiler to completely fail, then the problem must be solved immediately after detection.

The cost of replacing a section of a cast iron boiler

The cost of replacing a section of a cast iron boiler depends on the model of your equipment, its capacity, and the complexity of the work performed. The final price can be determined only after a visual inspection of the place of work by the master.

Is it possible to independently replace a section of a cast iron boiler?

Some equipment owners are trying to replace the section of the cast-iron boiler on their own. However, here they face a number of problems:

- How to disconnect a damaged section of a cast iron boiler from a package of sections.

- How to seal the joints between the installed sections.

- How not to damage adjacent sections and the package of sections as a whole.

- How to do the whole range of work without a special tool.

- How correctly, without distortions and overvoltage of the entire heat exchanger, pull off the package of sections.

Self-repair of a cast-iron sectional heat exchanger is quite problematic - as a rule, there is no necessary tool, there are no skills for such work. Despite the seeming simplicity of the process, there are frequent cases of damage to a new section due to improper installation, as well as damage to neighboring, previously whole sections. As a result, self-repair results in even higher costs than the involvement of a specialized installation organization.

Fast, high quality, reliable. With a guarantee!

We guarantee prompt and high-quality performance of the entire cycle of work on the replacement of sections on your boiler. The vast experience in carrying out belt work on cast iron boilers of various capacities allows us to assert that the work will be performed efficiently and on time! The assembly team will independently deliver all the necessary spare parts and consumables to your site - and this will not affect the cost of work, no additional payment for delivery.

After assembly and pressure testing of the heat exchanger, if no heavy lining device is required (Universal-6M boilers and similar), the boiler will be ready for normal operation. For the work performed, a guarantee from 6 to 12 months is provided, depending on the manufacturer of the boiler.

Homemade heating boiler

In addition to buying heating boilers presented on the market by well-known and not very international or domestic manufacturers, there is always an opportunity to make a heating boiler with your own hands. And while saving on a whole list of options, without which your heating system may well do. All that is needed for this is knowledge of the device and the principle of operation of the type of boiler you have chosen, materials, tools and equipment, as well as practical skills in working with them.

Almost any type of heating boiler can be built if desired. The main thing is to make the right choice, and for this you need to know the main advantages and disadvantages of the most popular types of heating equipment. AND so, heating boilers are:

It is not recommended to make boilers of this type on your own: technical requirements are imposed on gas equipment that you are unlikely to be able to satisfy in artisanal conditions.

Household electric boiler

The rather high popularity of this category of heating boilers is explained by the simplicity of the design and the relatively low safety requirements during installation and operation.

A huge drawback of electric boilers is the high prices for electricity. As a result, such equipment is used to provide periodic heating, for example, a summer house or garage.

- Liquid fuel

Homemade liquid fuel boiler

The design of such a boiler is not very complex. However, the cost and subtleties of setting the nozzles supplying fuel to the combustion chamber will make anyone think at least twice before starting to create a heating unit that runs on fuel oil or diesel.

- Solid fuel

Diy long burning boiler

Representatives of this type are optimal for heating both private houses and various objects of objects of the commercial or industrial sector. High efficiency and versatility in application provide solid fuel boilers with the highest demand on the market.

According to the principle of operation, solid fuel boilers are distinguished into wood, pyrolysis, long burning and pellet boilers. The most popular option for self-production is long-burning boilers, while pyrolysis and pellet boilers are used much less often due to the high cost of individual components.

Several conditions affect the design of the heating boiler:

- cost and availability of materials;

- type of fuel;

- way of circulation of the coolant.

Heat-resistant stainless steel demonstrates the greatest durability. However, it is she who has the highest price on the market, and its processing is a rather difficult task that cannot be dealt with without special equipment. The same applies to cast iron, which, however, is much cheaper than stainless steel. Traditionally, for the manufacture of heating boilers, sheet steel with a thickness of 4 mm or more is used - this option is relatively easy to process and, most importantly, it is quite reliable and durable.

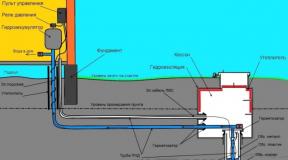

To ensure the natural circulation of the coolant, it is necessary to use heating circuits and connecting fittings of a large diameter, and place the storage tank at a height. If this is not possible, you will have to use a circulation pump - it will reduce the diameter of the pipes. However, the pumping system of the heating boiler is volatile, which must be taken into account when choosing the design and functionality of the unit.

The pipes that your boiler will be equipped with must have a diameter of at least 32 mm - a thick-walled steel pipe is suitable for their manufacture. The heating circuit should be made of galvanized steel, not forgetting about the sealing of the threaded connections.

Homemade wood-fired boiler

The cheapest option for self-manufacturing is a wood-burning boiler. Structurally, such a unit is two containers placed one inside the other. The inner one serves as a firebox, the outer one serves as a heating tank. The design of a wood-burning boiler is really simple, and it can work not only with wood, but also with other types of solid fuel.

The wood-fired boiler design includes:

- steel firebox (with a door);

- ash pan (with a door);

- firebox grates;

- soot collector;

- chimney;

- gate valve;

- inlet and outlet branch pipes;

- legs;

- cast iron cover.

Solid fuel boiler device

A big minus of a wood-burning boiler is low efficiency, that is, a huge consumption of firewood or a constant lack of heat in the house.

Pyrolysis boilers are more expensive to manufacture: they have two combustion chambers - for fuel and for pyrolysis gas, and some of their components are quite expensive by themselves. Nevertheless, such equipment is in great demand due to its cost-effectiveness - it fully pays for itself during only 3-4 seasons.

The classic scheme of a pyrolysis boiler includes:

- combustion chamber with nozzle;

- gasification chamber;

- air supply system;

- chimney system;

- loading chamber;

- water heat exchanger;

- coolant circulation system;

- temperature and pressure sensors;

- regulating valve.

The principle of operation of the pyrolysis boiler

Pellet boilers were invented at the end of the 20th century. They operate on pressed sawdust, and their main principle of operation is to transfer heat from the gas released during the combustion of the latter, which heats the coolant in the heat exchanger.

Diy pellet heating boiler

The pellet boiler design includes:

- housing;

- combustion chamber with air window and cleaning door;

- heat exchanger with a water circuit;

- smoke extractor;

- thermal insulation pad;

- automation of monitoring and control.

In pellet boilers, it is best to use cast iron heat exchangers: they have a higher heat transfer rate and are not subject to corrosion.

The main element of an electric heating unit is a thermoelectric heater (TEN) - it is necessary to convert electricity into heat. The body of the electric boiler can be made of any material, and the components necessary for its operation - regulators, sensors, etc. - can be bought at any specialized store.

Electric heating boiler device

Structurally, an electric boiler consists of:

- Heating element;

- expansion tank;

- circulation pump;

- safety valve;

- filtration unit.

The principle of operation of an electric heating boiler

The coolant in the system can circulate both naturally, for which it is necessary to provide for a height difference between the radiators and the boiler tank, and forced by means of a pump. The simplest version of an electric boiler is to install a heating element directly into the heating system. If this design is not suitable, you can design an electric boiler with a removable pipe - this will make it possible to quickly get to the heating element if repair or replacement is necessary.

The optimal solution for heating, say, a small cottage is a separately located small-sized electric boiler. The pipe of such a boiler will have a diameter of about 220 mm, and the body length will be no more than half a meter, which allows you to install it in almost any place, of course, taking into account safety rules.

The boiler body must be airtight. It is equipped with an opening for the entry of heated coolant into the heating system, as well as a pipe for the reverse supply of cooled water.

In addition to solid fuel and electric boilers, a number of alternative heating units are suitable for self-production:

- Induction boilers

They are transformers consisting of primary and secondary windings. In such a boiler, the electricity on the external winding is converted into eddy current, and the created magnetic field is transferred to the internal one, which gives energy to the coolant.

- Condensing boilers

They retain the thermal energy of the condensate, therefore they are considered more efficient than gas and even solid fuel. Steam condensation occurs in a heat exchanger with a special design - it is it that provides such boilers with a 15-20% advantage in efficiency over traditional gas equipment.

- Oil boilers

Such units evaporate the mining, and then burn its vapor. The energy thus obtained is transferred to a heat exchanger, which heats the heat agent of the heating system. Equipment of this type has two significant drawbacks - low efficiency and a large number of emissions into the atmosphere.

- Combined boilers

This equipment is universal in application, however, for its independent manufacture you need remarkable skill and excellent knowledge of the principles of work various kinds heating equipment. The individual components of such units can be quite expensive, but in general combined boilers able to pay off in no more than 5-6 seasons.

When manufacturing a boiler of any type, it is necessary to be guided by the requirements of the safety rules and the standards applicable to the category of heating equipment you have chosen.

A gas boiler complex mechanism. It can be divided into 3 main parts: electronics, gas pipes and burners, heat exchange unit (pump, tank, fan). You can repair yourself only the last part.

Attempts to restore the first two parts without proper skills, will lead to final damage boiler, gas leakage and other negative consequences.

Gas boilers rarely break. This is due to natural wear equipment, either because factory defect. Other cases of damage are necessarily associated with the following factors.

The boiler may break due to water. In the risk group, in the first place are dual-circuit devices used not only for heating, but also for hot water.

The fact is that rust from the pipeline, other fractions, clog the thin tubes of the heat exchanger over the year.

Avoiding Water Quality Troubles Will Help coarse filter. It is installed during installation. to the feed pipe liquids. For greater security, you can add to the system fine filter, or install a complete cleaning system.

Household appliances resistant to power surges and shutdown electricity. But a gas boiler is finer equipment. A power surge will cause the boiler to turn off or damage the electronics. A malfunction of the device or a power outage will cause the heating pipes to freeze.

In order to avoid sad consequences, they establish at least one of the additional devices.

- Stabilizer - a device that will solve the problem of power surges. Its size is small, it is installed both in an apartment and in a private house.

Photo 1. Resanta Lux electronic voltage regulator for a heating boiler. The device is mounted on a wall.

- Uninterruptable power source. Will equalize the input voltage. Allows the boiler to work for a while in the absence of electricity. It is appropriate to use both in the apartment and in the house.

- Gas generator. It does not affect the stability of the network in any way, but can save during a prolonged blackout. Used only in the private sector.

Attention! When buying a generator, check if it is really single phase.

Installation of sophisticated equipment layman will entail grave consequences. In frequent cases, the following problems occur:

- During installation neglected grounding. This leads to the accumulation of static on the device. In the event of an electric arc, boiler automation often fails.

- After installation did not release air from the system. The resulting plug will rupture the coolant pipes and break the pump.

- Violations in the harness gas boiler systems, with a cast-iron heat exchanger, will cause a split in an important part of the apparatus.

If the gas boiler is installed correctly, operational problems arise only due to weather conditions. In the cold winter, the desire to warm up pushes people to use the boiler in maximum mode. The equipment withstands such conditions, but the gas system does not. A decrease in fuel pressure leads to interruptions in the operation of the apparatus. Automation starts to turn off the boiler. The problem is that this can not be called a breakdown and eliminate it will not work.

Any malfunction of the gas boiler must be combated by a specialist. However, it is not always possible to use the services of a wizard, and breakdowns are trifling. Consider the problems that are solved independently.

Gas smell usually appears when it leaks from the threaded connection of the feed hose. If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Next, follow the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end wrench or adjustable spanner.

- Apply solution on all threaded connections. If bubbles begin to inflate, a leak has been detected.

- Close the gas valve.

- The key expand the connection. Wind up on an external thread FUM tape and collect everything back.

- Reapply the solution. and resume gas supply.

- If the leak is fixed and the smell of gas disappears, remove leftovers solution.

Attention! When the leak was not detected, block the gas, call a specialist.

If during the operation of the boiler the sound made by the turbine is lost or decreased - indicates a defective blower fan. For repair you will need: screwdriver, new bearing, cloth, grease.

- Necessary switch off boiler and shut off the gas.

- Remove the turbine.

- With a cloth to clear with turbine blades dust and soot.

- Inspect the electric coil fan for blackening. If everything is OK, go ahead or replace the fan.

- Disassemble the fan housing. Inside mounted on the turbine shaft bearing, his need to be replaced. Some fans have sleeve instead of the bearing. In this case, her need to be lubricated.

The turbine may also not work due to undervoltage network or control board malfunctions. The first is eliminated with the help of a stabilizer, but the second only by calling a specialist.

Chimney problems arise only at boilers floor type. This is due to its size and vertical position. Attachments do not need to clean the chimney.

Chimney consisting from metal parts, cleaned with a metal brush. It must be disassembled and mechanically removed accumulated soot. Whole the chimney is cleaned with special vacuum cleaners or chemicals. But for this it is necessary to call a professional.

Photo 2. Three ways to equip a chimney for a floor gas boiler. The first option is the hardest to clean.

Boiler overheating is associated with heat exchanger fouling. To clean the device you will need: special hydrochloric acid solution, adjustable spanner, FUM tape, metal brush. Next, follow the instructions:

- Turn off the boiler shut off gas and water.

- Remove heat exchangerusing an adjustable wrench.

- Clear him with a brush.

- Through the pipe pour in to heat exchanger acid solution. If foam appears, there is a lot of scale inside.

- Pour out solution and repeat procedure.

- Rinse.

- Install back preliminary wrapping all threaded connections with FUM tape.

Problems usually arise with burning electrode. If the burner flame goes out after a few seconds, and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler, turn off the gas.

To repair the electrode sandpaperby which sensor probes are strippedwithout removing it. If the breakdown remains, the sensor changes.

Exist two problemsthat cause the boiler to shut down spontaneously. The combustion sensor has broken or chimney clogged. Repair of both faults is described above in the article.

Watch the video that tells about malfunctions that occur during operation of the boiler.

Most boiler breakdowns are repaired independently, but this does not mean that you need to neglect the help of a specialist. Gas equipment is potentially life-threatening.

And do not forget about maintenance. Cleaning the heat exchanger and chimney will protect against possible damage.

The reasons why the boiler has flowed are actually not so many. First, corrosion may be the culprit. What is corrosion is the destruction of the metal structure under the influence of the external environment. The internal corrosion of a gas boiler is caused by the action of oxygen in the water, and the external corrosion by combustion products.

The next cause of the leak may be the low quality of the metal of which the heat exchanger is made and the quality of the joints of its joints.

High pressure in the system, or water hammer also cause leaks in the boilers. Burning the walls of the heat exchanger also gives a leak.

In some cases, when water drips from the boiler, and you think that your boiler is dripping, in fact, it may be condensation from the chimney that flows down the chimney and enters the burner. If this situation occurs frequently, a drip cup should be equipped in the chimney. When it drips near the circulation pump, a bolt located in its center may have loosened. Tighten the bolt.

Below we consider in more detail each case separately and describe what to do if this happened.

The heat exchangers installed in the heat generators can be made of copper, steel and cast iron. Each of them has its pros and cons. Copper heat exchangers are corrosion resistant and durable if the boiler is operated correctly. Steel heat exchangers are the most common, due to their low cost, resistant to thermal stresses, due to their ductility, but are more often subject to corrosion.

Heat exchanger corrosionCast iron is resistant to corrosion, has a long service life, although they are afraid of temperature extremes and water shocks. Most manufacturers do not use anti-corrosion coatings. But in the latest models of gas double-circuit boilers Ferroli (Ferroli), steel heat exchangers are coated with an anti-corrosion aluminum coating with environmental internal insulation.

On Baxi units (Baxi), copper heat exchangers are coated with a special composition against corrosion. Protherm (Proterm), Buderus and Beretta have a cast-iron heat exchanger, which is coated with a special composition from corrosion. In addition, such a heat exchanger consists of separate sections, which can be changed in case of damage, without completely changing the heat exchanger.

Wall-mounted boilers Rinnai, Celtic (Celtic), Bosch (Bosch) are equipped with copper heat exchangers, Vaillant (Vailant) and Navien - stainless steel, it is believed that they are less exposed to corrosion.

The formation of corrosion is greatly influenced by the frequent feeding of the boiler. Ideally, the so-called “dead water" without oxygen content should circulate in the heat generator. It is oxygen that contributes to the formation of corrosion.

If you often have to recharge the heat generator, you should eliminate the causes of the pressure drop in the unit. Oxygen corrosion forms an ulcer on the inside of the heat exchanger, which is very dangerous. Germinating inside, it forms through rust and destroys the heat exchanger.

The strength of the boiler depends on the quality of the welded joints. If there are caverns or irregularities in the weld, sooner or later this seam may leak. Especially dangerous is the void that is inside the seam. Ideally, the seams should be x-rayed, but not all manufacturers do this.

Although heating boilers are pressure vessels and must be subject to increased manufacturing requirements, marriage can sometimes happen. And, as a rule, drips from the heating boiler after the warranty ends. It is not always possible to brew the boiler inside and stop the leak.

It depends on how the heat exchanger is arranged. In models where a bithermal heat exchanger is installed (the secondary and primary are in the same housing, the heat exchange occurs due to the two-in-one design) this is problematic. But, even if you did it, as practice shows, it will not help you for long.

Excessive pressure in the system can also cause the boiler to leak. There can be many causes for high blood pressure. The main cause may be a malfunction of the expansion tank, air locks in the system, a clogged strainer, a malfunction of the safety valve, the make-up valve.

A malfunction of the safety valve is indicated by constantly leaking fluid from the tube. High pressure can not only crack the boiler, but also cause an explosion. Keep the pressure gauge and the relief valve in good working order; sometimes the valve sticks due to the formation of a layer of salts on it. Rinse it in citric acid.

Heating boiler safety valveCheck regularly that the pressure on the valve and in the expansion tank is consistent. When installing an expansion tank, it is necessary to calculate the volume of the coolant. How to calculate - there is a calculation formula, and the average value is -1.5 Atm or 0.2 Atm lower than in the system. For prevention, do not forget to rinse the filters at the inlet and outlet of the heating circuit, after recharging the system, it is necessary to air the batteries.

The cause of the leak can be burnout of the wall of the combustion chamber. Steel and cast iron burn out when carbon escapes from their composition, so the metal on the combustion chamber becomes thicker. As a rule, burnout occurs when the height of the combustion chamber is incorrectly set, the burner power is set incorrectly, the burner is not adjusted to the minimum and maximum power, and the flame is too high.

Burnout occurs when the boiler is constantly operating at maximum power, this occurs in case of insufficient insulation of the housing or when the heat generator is selected without taking into account the heated area.

When purchasing a boiler, read reviews on the Internet and give preference to positively proven manufacturers. It is better to buy a heat generator of slightly greater power, with reliable modulation of the flame and entrust the setting to specialists.

How to fix a leak - the leak elimination algorithm is the same both on solid fuel boilers, such as Don, CFM, and gas, for example, AOGV, Alixia 24, Ariston (Ariston), Deu, Arderia, Electrolux.

- Turn off the device.

- Drain the water.

- Wait for the boiler to cool completely.

- Remove the heat exchanger, as described below.

- Solder, eliminate the fistula.

What does a heat exchanger look like - it is a metal or cast-iron casing, heated by the flame of a burner and transferring the thermal energy of the liquid that is inside it.

To disassemble it and solder it yourself, you need to remove the front panel, the protective cover and the protection of the combustion chamber with a long screwdriver. Then disconnect the sensor wires and pipelines suitable for the heat exchanger, try not to damage the pipes and tubes, hold them with a wrench.

To then connect everything correctly, you should first take a picture of the inside of the heat generator. Then disconnect the fan and smoke detector. When removing the heat exchanger, do not use force or make sudden movements; do everything with extreme caution.

If you find a breakthrough between the circuits in the tube - it is impossible to seal such a hole, you will have to change the heat exchanger. It is impossible to weld the heat exchanger; soldering with a gas torch should be used.

Soldering heat exchangerIn order to do soldering with your own hands, you must first clean the place where the fistula has formed. This can be done with fine sandpaper. Soldering is carried out by a gas-oxygen mixture with solder containing the same chemical elements from which the heat exchanger is made.

It is impossible to use tin in this case, since such repair after some time will again lead to the formation of a fistula. After soldering, a protective coating should be applied to the problem area, for example, a layer of aluminum.

When buying a heat generator, carefully review the quality of the soldering of the joint seams, both on the water and on the primary heat exchanger, there should not be any sagging, unevenness.

Set the burner according to the instructions in the manual. To avoid the appearance of fistulas, it is necessary to take timely measures in the presence of high pressure and airiness in the system. Avoid frequent replenishment of the system with water, find out the cause of the pressure drop in this case and eliminate it.

✔ ✉ Feedback Rate this article:- → This boiler room needs repair! There is nothing to serve here. The concepts of repair and maintenance of boiler rooms are subtle to the uninitiated, but significant differences: The following is an approximate list of the most frequently performed repairs and maintenance of boiler rooms. The list of works during the maintenance of the boiler room1 The list of works during the maintenance of the boiler room2 The list of works when the boiler room needs to be repaired3 Our company repairs boilers on any type of fuel except for the following cases: Inspection of the boiler room, taking instrumentation readings Tightening detachable connections Cleaning all filters Pumping expansion tanks and accumulators Adding coolant if necessary Replacing magnesium anodes in boilers Hydraulic work 90 ...

→ Flushing the heating system - the process of flushing pipes and pipelines of the heating system using various methods, with the aim of ridding the internal walls of the heating system of scale formed during operation, consisting of salts of calcium, magnesium, sodium and other non-metals, various organic and inorganic products. Scale collecting on the walls of pipes and batteries is the cause of numerous problems. Firstly, it contributes to the accelerated mechanical wear of the pipes themselves. And secondly, the heat transfer of the heating system is reduced. According to experts, scale, even up to 1 mm thick, reduces heat transfer by approximately 15%. Over time, the key parameters of the system change in the negative direction90 ...

→ Order the service Engineer check-out for diagnostics tel: 8 (495) 744-67-74 \u003d 24 hours a day, 7 days a week. What the engineer will do: inspection of heating equipment in the boiler room; diagnostics of circulation pumps; inspection of equipment and piping with a thermal imager for thermal conductivity, etc. Without heating is not life. It’s very unpleasant to stay without heating in winter or on the eve of frost realize that the house is warming in parts or the radiators are “slightly warm”. Preparing the heating system for winter, which must be done strictly in steps, will help to avoid problems. Steps for preparing a heating system1 Steps for preparing a heating system2 Preparing a house for the heating season3 Installing heating First step90 ...

→ Replacement, installation, installation of a heating boiler in a house or a cottage1 Replacement, installation, installation of a heating boiler in a house or a cottage1.1 Upon arrival at the facility, the engineer will carry out all the necessary surveys to further estimate the replacement of the heating boiler: 1.2 Estimated cost of the installation of the boiler equipment: Well-designed and high-quality installed heating in the house is the key to a comfortable stay in the country outside your own home. Modern heating systems are thought out to the smallest detail and are almost completely automated, so the owner once again does not have to worry about how hot the batteries are in the house. And what to do in such90 ...

→ In order not to be unfounded about the importance of incoming water, we give a list of regulatory documents regulating the quality of water for powering various boiler equipment: Installation of water purification and softening filters for a boiler and heating1 Installation of water purification and softening filters for a boiler and heating1.1 Water treatment - is it 1.2 Consequences of poor-quality water 1.3 Water treatment - first of all, saving on repairs! The device of our everyday life is impossible without the use of water, which is used not only to quench our thirst and prepare food, but also to heat our housing, if we are talking about a country house. In this case, 90 ...

→ The examination can be carried out in the oral consultation mode, which includes the expert’s visit to the object, visual inspection and instrumental measurements. On the day of departure at the facility, a defective statement is issued, which is a list of detected defects signed by an expert. Construction expertise of an apartment1 Construction expertise of an apartment2 When does it become necessary to conduct a construction expertise of an apartment? 3 Scope of work 3.1 Conclusion includes: The modern rhythm of life makes us increasingly prefer living in multi-apartment buildings, and the construction or purchase of individual residential buildings is relegated to the background. However, the quality of multi-story buildings, as well as the layout and others90 ...

→ Independent construction examination of a private house1 Independent construction examination of a private house2 Possible types of surveys country house When buying a finished property, it is important for the buyer to be confident in its quality, reliability and durability. Rate the quality construction work, the possible life of the structure, the need for repairs will help to conduct a construction examination of the house before buying. It becomes especially important to conduct such a technical examination when buying country houses. Poor performance of work at the construction stage can cause a lot of different problems, but they will appear only during the constant operation of the structure. Accordingly, the future owner of the house will find out about them much later than the moment90 ...

→ Heating service - Replacing the pump With the approach of cold weather, all adequate people to one degree or another think about the issues of heating their own home. This topic is especially relevant for private homes and cottages. As a rule, monitoring is carried out ......

→ Heating service - Replacing the heat exchanger The main purpose of the heating system is to maintain a warm and comfortable environment in the room. The design of the heating system is based on the interaction of key elements, one of which is the heat exchanger. The heat exchanger is responsible for the distribution of heat in ......

→ Heating service - Modernization of the boiler room. Owners of modern houses equipped with their own boiler house are well aware of the main advantages of such systems, the main of which is effective heating of homes with low financial costs. But the heating system needs constant and systematic modernization. TO......

→ Heating service - Prevention of a boiler Competent heating service is an important component of the trouble-free operation of any type of heating, from the most common gas to another, even rare, alternative. Maintenance includes a lot of work - from visual inspection to partial replacement ......

→ The choice of pipes and radiators1 The choice of pipes and radiators2 Calculation of heating radiators3 The layout of the heating pipes For the heating system of an individual house, the following types of pipes can be used: Polypropylene; PEX-a (pipes made of cross-linked polyethylene); Metal-plastic; Copper; Steel. The most popular are polypropylene and pipes made of cross-linked polyethylene due to ease of installation, low cost, high operational parameters. Copper pipes are the most expensive, but the most reliable and durable material characteristics due to the thermal conductivity of copper. Copper pipes are not afraid of water hammer and can withstand temperatures up to 500 degrees. Stainless steel pipes are also quite durable, but due to the complexity of installation, the cost of the system is 90 ...

→ Our organization produces turnkey installation of heating cottages of the city of Vidnoe. We provide customers with a full range of services for the installation of heating systems in the country. The heating system is mounted single-pipe or two-pipe. Installation of a one-pipe system. 1 Installation of a single-pipe system. 2 Installation of a two-pipe heating system in a private house. 3 Installation of a system. 3.1 Order installation of heating of a private house. 4 Installation of a boiler room in Vidnoye. services. Installation of a single-pipe heating system is a supply of coolant for all batteries and other circuits through a single pipe, which performs the supply and removal of the coolant. Single pipe heating is characterized by a low 90 ...

→ The LLC DESIGN PRESTIGE company carries out installation of turnkey heating of a private house. We provide our customers with installation services for heating systems in the country or in a private house. The heating system can be single-pipe or two-pipe. Installation of a one-pipe system. 1 Installation of a single-pipe system. 2 Installation of a two-pipe heating system in a private house. 3 Installation of a system. 3.1 Order installation of heating for a cottage. 4 Installation of a boiler room in the city of Vereya. 4.1 Installation of boiler piping. consists of several components: 6 Warranty on the services provided. The installation of single-pipe heating represents the passage of the coolant to all batteries and other consumers through one pipe, which is designed90 ...

→ Choosing a heating system Choosing a heating system for a summer residence is a difficult problem. In the old cottages still reigns ......

→ House heating - what are the heating systems and wiring diagrams1 House heating - what are the heating systems and wiring diagrams2 How to make heating in a private house3 Choosing heating - which heating system is better for a private house 3.1 The main criteria for choosing a heating boiler are: 4 Water heating system5 Distribution of heating pipes 5.1 Single-pipe heating system of a house 5.1.1 How to reduce heat loss with a single-pipe heating system: 5.2 Two-pipe heating system of a house 5.3 Collector (radial) distribution 5.4 Water heating of a floor in a house 5.4.1 Installation of a warm water floor system is carried out in three stages : 6 Steam heating at home7 Air heating at home7.0.1 Components of an air system90 ...

→ ...

→ Individual heating system If your cottage or holiday village does not have a central heating system ◄, then you will have to organize the installation of heating and the installation of water supply yourself in your ......

→ Gravity heating Modern vacation home in terms of comfort is not inferior to a city apartment. The development of building technology has made ......

→ Turnkey heating Many of us remember when air heating in a room was carried out exclusively with the help of a furnace, which caused a lot of inconvenience, since it was impossible to achieve uniform heating of the room, ......