Chiller with remote condenser cooling. Chiller with remote condenser. Hydraulic diagram of the chiller, hydronic module

Obtaining artificial cold is based on simple physical processes: condensation, compression and expansion of working substances. The working substances used in refrigeration units are called refrigerants.

Chillers differ:

- by design (absorption, with built-in or remote condenser - condenser and non-condenser);

- type of condenser cooling (air or water);

- connection diagrams;

- the presence of a heat pump.

Benefits

- Ease of use - all year round, the set parameters are automatically maintained in each room in accordance with sanitary and hygienic standards;

- System flexibility - the distance between the chiller and fan coil units is limited only by the pump power and can reach hundreds of meters;

- Economic advantage - operating costs are reduced;

- Environmental advantage - harmless refrigerant;

- The construction advantage is the flexibility of the layout, the minimum expenditure of usable space for the placement of the refrigeration machine, because it can be installed on the roof, technical floor of buildings, in the yard;

- Acoustic advantage - low-noise design of the units;

- Safety - the risk of flooding is limited by the use of shut-off valves.

Chiller types

The absorption type is a very promising area in the development of refrigeration technology, which is becoming increasingly widespread due to the pronounced modern trend towards energy saving. The fact is that for absorption refrigeration machines, the main source of energy is not electric current, but waste heat, which inevitably arises in factories, enterprises, etc. and irretrievably emitted into the atmosphere, be it hot air, air-cooled hot water, etc.The working substance is a solution of two, sometimes three components. The most common binary solutions of an absorber (absorbent) and a refrigerant that meet two main requirements for them: a high solubility of the refrigerant in the absorbent and a significantly higher boiling point of the absorbent compared to the refrigerant. Water-ammonia solutions (ammonia-water refrigerating machines) and lithium bromide-water (lithium bromide machines) are widely used, in which, respectively, water and lithium bromide are absorbents, and ammonia and water are refrigerants. The operating cycle in absorption chillers (see the figure below) is as follows: in the generator, to which the waste heat is supplied, the working substance boils, as a result of which an almost pure refrigerant boils away, because its boiling point is much lower than that of the absorbent.

The refrigerant vapor enters the condenser, where it cools and condenses, giving off its heat to the environment. Further, the resulting liquid is throttled, as a result of which it is cooled during expansion) and is sent to the evaporator, where, evaporating, it gives its cold to the consumer and goes to the absorber. An absorbent is supplied here through the throttle, from which the refrigerant boiled away at the very beginning, and absorbs vapors, because we have indicated above the requirement for their good solubility. Finally, the absorbent saturated with refrigerant is pumped to the generator, where it boils off again.

The main advantages of absorption chillers:

- Ideal solution for creating trigeneration in the enterprise. Trigeneration complex is a complex that allows today, to minimize the cost of electricity, hot water supply, heating and cooling for the enterprise by using its own cogeneration power plant in conjunction with an absorption chiller;

- Long service life - within 20 years, before the first major overhaul;

- low cost of the produced cold, cold is produced almost free of charge, because assorption chillers simply recycle excess heat;

- Reduced noise and vibration levels, as a result of the absence of compressors with electric motors, as a result - quiet operation and high reliability;

- The use of refrigeration / heating units with a direct-operated flame gas generator eliminates the need for boilers, which must be used in conventional installations. This reduces the initial cost of the system and makes absorption chillers competitive with conventional systems that use boilers and chillers;

- Provide maximum energy savings during peak periods. In other words, without consuming electricity to produce cold / heat, absorption chillers do not overload the power grid of the enterprise even at times of peak loads;

- There is the possibility of combining into steam district systems with an efficient double effect refrigeration unit;

- It is possible to distribute the load under conditions of maximum performance in cooling mode. The device handles the critical load in cooling mode with minimal power consumption through the use of chillers with a direct-acting flame gas generator or a steam-heated generator;

- Allows the use of emergency power generators of lower power, since the energy consumption of absorption refrigeration units is minimal when compared to electric refrigeration units;

- Ozone safe, does not contain ozone depleting refrigerants. Cooling is carried out without the use of substances containing chlorine;

- The overall impact on the environment is reduced to a minimum, since the consumption of electricity and gas, which causes the greenhouse effect and, as a result, global warming, is reduced.

An absorption chiller is a machine that produces chilled water using residual heat from sources such as steam, hot water or hot gas. Chilled water is produced according to the principle of cooling: a liquid (refrigerant) that evaporates at a low temperature absorbs heat from its environment during evaporation. Pure water is usually used as a refrigerant, while lithium bromide (LiBr) solution is used as an absorbent.

How absorption refrigeration systems work

In absorption refrigeration systems, the absorbent, generator, pump and heat exchanger replace the compressor of the steam compressor cooling systems (mechanical cooling). The other three (3) components also found in mechanical refrigeration systems, i.e. expansion valve, evaporator and condenser, are also used in absorption refrigeration systems.

Evaporation stage of absorption coolers

Refer to Figure-2 for a schematic explanation of the absorption cooling process. Like mechanical refrigeration, the cycle "begins" when the high pressure liquid refrigerant from the condenser passes through the expansion valve (1 in FIG. 2) into the low pressure evaporator (2 in FIG. 2) and collects the Sump in the evaporator.

At this low pressure, a small amount of Freon begins to evaporate. This evaporation process cools the remaining liquid refrigerant. Likewise, the transfer of heat from the relatively warm process water to the currently cooled refrigerant causes the latter to vaporize (2 in FIG. 2) and the resulting vapor is fed into the lower pressure absorber (3 in FIG. 2). As the process water loses heat to the refrigerant, it can be cooled to significantly lower temperatures. At this stage, chilled water is actually obtained by evaporating the freon.

Absorption stage of absorption coolers

The absorption of refrigerant vapors in lithium bromide is an exothermic process. In the absorber, the refrigerant is "sucked in" by the absorbing solution of lithium bromide (LiBr). This process not only creates a low pressure region that pulls a continuous flow of refrigerant vapor from the evaporator into the absorber, but also causes the vapor to condense (3, in FIG. 2) as it releases the heat of vaporization provided to the evaporator. This heat, together with the heat of dilution, generated by mixing the refrigerant condensate with the absorbent, is transferred to the cooling water and released in the cooling tower. Cooling water is a utility at this stage of cooling.

Regeneration of lithium bromide solution

As the lithium bromide absorbent absorbs the refrigerant, it becomes more and more diluted, reducing its ability to absorb more refrigerant. The absorbent must be re-concentrated to continue the cycle. This is achieved by continuously pumping the diluted solution out of the absorber to the low-temperature generator (5 in Figure 2), where the addition of residual heat (hot water, steam or natural gas) boils (4, Figure 2) Refrigerant from the absorbent. This generator is often used to recover waste heat from the plant. As soon as the refrigerant is removed, the reconcentrated lithium bromide solution is returned to the absorber ready to resume the absorption process, and the free freon is sent to the condenser (6, in Fig. 2). Waste heat from steam or hot water is useful at this stage of regeneration.

Condensation

The refrigerant vapor welded in the generator (5 in Figure 2) returns to the condenser (6), where it returns to its liquid state when the cooling water raises the heat of vaporization. It then returns to the expansion valve where a full cycle is completed. During the condensation stage, the cooling water becomes useful again.

Various technologies for absorption chillers

Absorption chillers can be disposable, double or newer, which is a triple effect. Single effect machines have one generator (see diagram above, Figure 2) and have a COP less than 1.0. Double effect machines have two generators and two capacitors and are more efficient (typical COP values\u003e 1.0). Triple effect machines add a third generator and capacitor and are most efficient: COP\u003e 1.5 typical.

Pros and cons of absorption chiller systems

The main advantage of absorption chillers is lower energy costs. Costs can be further reduced if natural gas is available at a low cost or if we can use a low-grade heat source that is otherwise lost in the plant.

The two main drawbacks of absorption systems are their size-weight, and their need for larger cooling towers. Absorbent chillers are larger and heavier compared to electric chillers of the same capacity.

Vapor compression chillers are currently the most common type of refrigeration equipment. Cold generation is carried out in a vapor-compression cycle, which consists of four main processes - compression, condensation, throttling and evaporation - using four main elements - a compressor, a condenser, a control valve and an evaporator - in the following sequence: The working substance (refrigerant) in a gaseous state is supplied to compressor inlet with pressure P1 (~ 7 atm) and temperature T1 (~ 5 ° C) and is compressed there to pressure P2 (~ 30 atm), heating up to temperature T2 (~ 80 ° C).

Then the freon goes to the condenser, where it is cooled (as a rule, due to the environment) to the temperature T3 (~ 45C), while the pressure ideally remains unchanged, but in reality it falls by tenths of an atm. During the cooling process, freon condenses and the resulting liquid enters the throttle (an element with high hydrodynamic resistance), where it expands very quickly. At the outlet, a vapor-liquid mixture with parameters P4 (~ 7 atm) and T4 (~ 0С) is obtained, which enters the evaporator. Here, freon gives its cold to the coolant flowing around the evaporator, heating up and evaporating at constant pressure (in fact, it will fall by tenths of an atmosphere). The resulting cooled coolant (Tx ~ 7C) is end product... At the outlet of the evaporator, it has parameters P1 and T1, with which it enters the compressor. The cycle is closed. The driving force is the compressor.

Refrigerant and heat carrier

We especially note the separation of similar at first glance terms - refrigerant and coolant. A refrigerant is a working substance of the refrigeration cycle, during which it can be in a wide range of pressures, and also undergo phase changes. The coolant does not change (phase changes) and serves to transfer (transfer) heat (cold) over a certain distance. Of course, an analogy can be drawn by saying that the driving force of the refrigerant is a compressor with a compression ratio of about 3, and the coolant is a pump that increases the pressure by 1.5-2.5 times, i.e. the figures are comparable, but the fact of the presence of phase changes in the refrigerant is fundamental. In other words, the coolant always works at temperatures below the boiling point for the current pressure, while the coolant can have a temperature both below and above the boiling point.Classification of vapor compression chillers

By installation type:

Outdoor installation (built-in condenser)

Such units represent a single monoblock installed outdoors. Convenient in that it allows you to exploit unexploited areas - the roof, open areas on the ground, etc. It is also a cheaper solution. At the same time, the use of water as a heat carrier is associated with the need to drain it for the winter period, which is inconvenient in operation, therefore non-freezing liquids are used, both new salt and traditional - solutions of glycols in water. In this case, it is necessary to recalculate the operation of the chiller for each specific coolant. Note that all today's antifreeze solutions are 15-20% less effective than water. The latter is generally difficult to surpass - the high heat capacity and density by the standards of liquids make it an almost ideal heat carrier, if not for such a high freezing point.

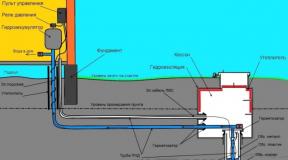

Indoor installation (remote condenser)

The situation here is practically the opposite compared to the previous version. The chiller consists of two parts - a compressor-evaporation unit and a condenser, connected by a freon line. Sometimes quite valuable areas are required inside the building, while space is still needed outside for placing the condenser, albeit with significantly lower requirements both in terms of area and mass. Indoor chillers have no problem with water use. We also mention the slightly higher energy consumption of the compressor and the increased pressure loss due to the extended route (from the chiller to the condenser), which, by the way, is also limited in length by the compressor.

By the type of condenser version:

Water cooling

However, in some cases water-cooled condenser is used. In this case, the condenser is a plate, plate-fin or pipe-in-pipe heat exchanger. Water cooling significantly reduces the size of the condenser and also allows for heat recovery. But the resulting heated water (about 40C) is not a valuable product; often it is simply sent for cooling to cooling towers, again giving off all the heat to the environment. Thus, water cooling is really beneficial if there is a consumer of heated water. In any case, water-cooled chillers are more expensive than air-cooled chillers, and the entire system as a whole is more complex in design, installation and operation.Traditionally, cooling towers are used to cool the condenser of refrigeration machines, in which water heated in the condenser is sprayed through nozzles in a stream of moving outside air, and in direct contact with the air is cooled to the temperature of a wet outside air thermometer, then entering the condenser. This is a rather bulky device that requires special maintenance, installation of a pump and other auxiliary equipment. Recently, so-called "dry" cooling towers or condenser coolers have been used, which represent a surface water-to-air heat exchanger with axial fans, in which the heat of water heated in the condenser is transferred to air, which is circulated through the heat exchanger by axial fans.

In the first case, the water circuit is open, in the second case, it is closed, in which it is necessary to install all the necessary equipment: a circulation pump, an expansion tank, a safety valve, and shut-off valves. To prevent water freezing when the chiller is operating in cooling mode at negative outdoor temperatures, the closed loop is filled with a water solution of antifreeze liquid. When a condenser is water cooled, the heat of condensation is also wasted and contributes to thermal pollution of the environment. If there is a heat source, such as a hot water system or a process line, it may be useful to use the heat of condensation during the cold generation period.

By the type of hydronic module:

With an external hydronic module

The remote hydronic module is used, firstly, when the built-in power is not enough; secondly, if redundancy is required (note that one standby pump is allowed in the built-in hydronic modules); thirdly, if for some reason the internal installation of the pumps is desirable. The system becomes flexible, and the length of the route is practically unlimited, because the pumps are also very powerful. At the same time, there are ready-made pumping stations that include pumps and an expansion tank and automation, and are compactly assembled on a base frame.

By type of condenser fans:

Chiller options

- free cooling function. Practically indispensable for chillers operating in cold seasons. A reasonable question arises, why use a vapor compression cycle for cooling, if it is already cold outside. The answer comes by itself - the coolant should be directly cooled with street air. In the refrigeration system, the most common temperature schedule is 7 / 12C, which means that theoretically, at street temperatures below 7C, it is already possible to use free cooling. In practice, due to under-recovery, the area of \u200b\u200bapplication is somewhat narrowed - at temperatures of 0C and below, the refrigeration capacity from freecooling reaches nominal values.

Body pump - this is the chiller operating mode “for heating”. The vapor compression cycle works in a slightly different sequence, the evaporator and condenser change their roles and the coolant is not cooled, but heated. By the way, let us note that although the chiller is a refrigeration machine, which gives three times more cold than it consumes, it is even more efficient as a heater - it will give four times more heat than it consumes electricity. The heat pump mode is most common in public and administrative buildings, sometimes used for warehouses, etc.

Compressor soft start - an option that allows you to get rid of high starting currents, exceeding the working ones by 2-3 times.

Chiller typology

The source of cold in air-water air conditioning systems is a chiller - a water-cooled chiller. There are chillers of various types depending on the method of condenser cooling, the type of equipment: monoblock or with a remote condenser, with or without a built-in hydronic module, operating mode (cooling only or cooling and heating). Manufacturers are constantly modernizing their equipment based on the latest technological and design developments.The range of chillers produced in recent years has been significantly updated due to the widespread use of new more efficient types of compressors: scroll, single-screw, twin-screw, which are gradually replacing reciprocating compressors in the range of small, medium and large capacities. The range of chillers with a built-in hydraulic module has expanded, including those with an accumulation tank.

Plate and surface heat exchangers are more often used as evaporators, which made it possible to reduce the dimensions of the units and their weight. Recently, manufacturers have begun to release chillers based on environmentally friendly R407 ° C freons,. Depending on the method of condenser cooling, refrigeration units are divided into air-cooled and water-cooled chillers. Chillers with an air-cooled condenser are most widely used, when heat is removed from the condenser by air, more often outside.

This method of heat removal requires installing it outside the building or the use of special measures that provide this method of cooling. Air-cooled condenser chillers are available in a monoblock design, when all the elements of the chiller are in one unit, and chillers with a remote condenser, when the main unit can be installed indoors, and the condenser cooled by outside air is located outside the building, for example, on the roof or in the yard . The main unit is connected to an air condenser installed outside the building with copper freon conduits. Monoblock Chillers

Axial Fan Chillers

Monoblock chillers are available with axial fans and centrifugal fans. Axial fans cannot work on the ventilation network, therefore, chillers with axial fans should only be installed outside the building, while nothing should prevent the air from entering the condenser and the fans blowing it out. Axial fan chillers can be manufactured in various versions: 1 - standard, 2 - with full heat recovery, 3 - with partial heat recovery, 4 - for cooling an aqueous non-freezing solution of ethylene glycol in the operating temperature range from + 4 ° C to −7 ° FROM.

It is possible to design a chiller with an additional method of regulating cold output. With the versions of chillers 1, 3, the heat of condensation is transferred to the outside air and is irretrievably lost. With the versions of chillers 2 and 4, additional shell-and-tube heat exchangers are installed that duplicate the condenser completely in version R (using 100% condensation heat to heat water) or partially (using 15% condensation heat to heat water).

In option 4, an additional shell-and-tube condenser is installed on the discharge line after the compressor in front of the main air condenser. Chiller configuration can be: ST-standard; LN - with a reduced noise level, which is achieved by the device of a sound-absorbing casing for the compressor and a decrease in the rotation speed of the axial condenser fan in comparison with the standard configuration; EN - with a significant reduction in noise level, which is achieved by installing a sound-absorbing casing for the compressor, increasing the living area of \u200b\u200bthe condenser for air passage and lowering the rotational speed of the axial fan, as well as installing the compressor on spring anti-vibration mounts, using flexible inserts on the discharge and suction pipelines of the refrigeration unit contour.

The requirements for the sound power level created by a working chiller with axial fans when installed outside the building may not be very high if there are no special requirements for the noise level in the building where this building is located. If such restrictions exist, it is necessary to calculate the sound pressure level in the room of the noise emitted by the chiller, and if necessary, use chillers of a special configuration.

Centrifugal Fan Chillers

Centrifugal fan chillers are designed for indoor installation. The main requirements for these units: compactness and low noise level associated with indoor installation. This type of chiller uses centrifugal fans with a low rotation speed, most of the sizes of small and medium capacity have a scroll compressor that is characterized by low noise level, in sizes with a sealed piston compressor it is placed in a special soundproof casing. The side panels of the casing of such chillers have a sound-absorbing coating from the inside, along with the standard ST configuration, low noise SC configuration, where a semi-hermetic piston compressor is placed in a noise-absorbing casing and there are flexible inserts on the discharge and suction pipelines of the refrigeration circuit.

When choosing this type of chiller and its placement, it is necessary to ensure a free supply of cooling air to the chiller and the removal of air heated in the condenser. This is done with the help of suction and discharge air ducts, and a ventilation network is formed consisting of a centrifugal fan, an air heater (chiller condenser), air ducts, intake and exhaust ventilation louvres. The dimensions of the latter are selected based on the recommended air speeds in the cross-section of the grilles and air ducts.

It is necessary, on the basis of aerodynamic calculation, to determine the pressure loss in the ventilation network. Pressure losses in the ventilation network must correspond to the pressure developed by the centrifugal fan, with the value of the air flow cooling the condenser. If the pressure of the centrifugal fan is less than the pressure loss in the ventilation network, it is possible to apply a more powerful electric motor to the centrifugal fan by special order. Ducts must be connected to the chiller using flexible inserts so that vibration is not transmitted to the ventilation network.

Chiller performance

Depending on the capacity, the chillers are equipped with three types of compressors: scroll compressors for low (recently shifted towards medium) capacity, single-screw compressors for medium and high capacity twin-screw compressors for medium capacity, hermetic piston compressors for low capacity and semi-hermetic piston compressors for average performance. Scroll and screw compressors as more effective in a certain range of performance compared to piston compressors gradually replace the latter. Chillers are available in two versions: working only in the chiller mode and working in two modes: the chiller and the thermal one. In air-cooled chillers, which provide for operation in the heat pump mode, reversal of the refrigeration cycle is provided, in water-cooled chillers, water circuit reversal is provided.Chiller diagram with integrated hydraulic module

In the embodiment, the chiller unit includes: a circulation pump on the return pipe, a membrane expansion tank, a safety valve for water, a drain valve, a water filling unit, a pressure gauge, and a differential pressure switch.

Energy-saving technology in chillers

When developing modern climate control equipment, special attention is paid to the problem of energy conservation. In Europe, the amount of energy consumed by the equipment during the annual operation cycle is one of the main criteria for making a decision when considering proposals submitted for tender. Today, a significant potential for improving energy efficiency is the development and creation of climate technology, which is able to cover the load schedule as accurately as possible under constantly changing working conditions. For example, according to studies conducted by Clivet, fluctuations in the average load on the air conditioning system during the season are up to 80%, while working at full capacity is needed only a few days a year.

At the same time, the daily schedule of thermal excesses is also uneven with a pronounced maximum. Traditionally, two identical compressors are installed in chillers with a capacity of 20–80 kW and two independent refrigeration circuits are made. As a result, the unit is able to operate in two modes at 50% and 100% of its rated power. The new generation of chillers with refrigerating power from 20 to 80 kW allows for three-stage capacity control. In this case, the total refrigeration capacity is distributed between the compressors in the ratio of 63% and 37%.

For new generation chillers, both compressors are connected in parallel and operate on the same refrigeration circuit, that is, they have a common condenser and evaporator. Such a scheme significantly increases the energy conversion coefficient (KPI) of the refrigeration circuit when operating with a partial load. For such chillers, at 100% load and outdoor temperature 25 ° С KPI \u003d 4, and when operating at 37% KPI \u003d 5. Considering that 50% of the time, the chiller operates with a load of 37%, which gives significant energy savings.

For the effective implementation of the new solution, microprocessor controllers are installed on the chillers, which allow:- control all operating parameters of the equipment;

- adjust the set value of the water temperature at the outlet of the chiller in accordance with the parameters of the outdoor air, technological processes or commands from a centralized control system (scheduling);

- select the optimal power control step;

- in case of real need, quickly and efficiently perform a defrost cycle (for models with a heat pump).

As a result, minimization of short-term compressor starts automatically occurs, optimization of compressor operation time and adjustment of water parameters at the outlet of the chillers in accordance with real needs. As the tests showed, on average, only 22 compressors turn on during the day, while the compressors of conventional chillers turn on 72 times.

The average annual KPI of the chiller reaches 6, and the energy saving, when using modern chillers instead of the usual ones, is 7.5 kWh per 1 m2 of the area of \u200b\u200bthe serviced object per season, or 35%. Another important advantage provided by the use of new chillers is that the need to install bulky storage tanks disappears, and the circulation pump built into the chiller body eliminates the need for an additional pump station.

As is known, the type of compressors used is of great importance for the accuracy of the execution of the chiller load schedule. Traditionally, high-capacity chillers used piston or screw compressors. A piston compressor has a large number of moving parts and, as a result, low efficiency due to large friction losses. During operation of reciprocating compressors, a high level of noise and vibration occurs, and there is also a need for their regular maintenance. Screw compressors, in turn, have a complex structure, and, as a result, a very high cost. The production of screw compressors is not very profitable.Maintenance of such compressors is laborious and requires highly qualified personnel. In recent years, new SCROLL compressors have appeared on the market, which are devoid of the characteristic disadvantages of reciprocating and screw compressors. Scroll compressors have high energy efficiency, low noise and vibration and are maintenance free. This type of compressor is simple in design, very reliable and, at the same time, inexpensive. However, the performance of Scroll compressors, as a rule, does not exceed 40 kW.

The use in modern chillers of many small but very reliable compressors such as Scroll, as well as several refrigeration circuits, made it possible to obtain a very “maneuverable” chiller that is capable of delivering the required refrigerating power with high accuracy. Obviously, the use of such a chiller makes it unnecessary to install a pump station, and a wide selection of pumps of different capacities built into the chiller body solves all issues related to the circulation of chilled water. Of particular note are the very small inrush currents of the new equipment. After all, the launch of small Scroll compressors with low power consumption occurs alternately, in accordance with the increase in load on the unit.

For all chillers of the latest generations, a modern microprocessor control system allows you to adjust the set value of the water temperature at the outlet of the chiller in accordance with the parameters of the outdoor air, technological processes or commands from a centralized control system (scheduling). From an economic point of view, using a large number of Scroll compressors and installing an integrated circulation pump instead of a separate pump station is more profitable than using expensive, powerful and complex semi-hermetic compressors. Advantages and disadvantages of chillers

Benefits

Compared to split systems in which gas refrigerant circulates between the chiller and local units, chiller-fan coil systems have the following advantages:- Scalability. The number of fan coils (loads) on the central refrigeration machine (chiller) is practically limited only by its performance.

- Minimum volume and area. The air conditioning system of a large building may contain a single chiller, occupying a minimum volume and area, the facade's appearance is maintained due to the absence of external air conditioning units.

- Virtually unlimited distance between the chiller and fan coil units. The length of the routes can reach hundreds of meters, since with a high heat capacity of the liquid coolant, the specific losses per linear meter of the route are much lower than in systems with gas refrigerant.

- Wiring cost. To connect chillers and fan coils, ordinary water pipes, shutoff valves, etc. are used. Balancing water pipes, that is, balancing the pressure and flow rate of water between individual fan coils, is much simpler and cheaper than in gas-filled systems.

- Safety. Potentially volatile gases (gas refrigerant) are concentrated in the chiller, which is usually installed in the air (on the roof or directly on the ground). Pipe wiring accidents inside the building are limited by the risk of a flood, which can be reduced by automatic shut-off valves.

disadvantages

- Chiller-fan coil systems, in the strict sense, are not ventilation systems - they cool the air in every air-conditioned room, but do not affect the air circulation. Therefore, to ensure air exchange, the chiller-fan coil systems are combined with air (roof) air conditioning systems, the chillers of which cool the outside air and supply it to the premises through a parallel forced ventilation system.

- Being more economical than roof systems, chiller-fan coil systems certainly lose in cost to VRV and VRF systems. However, the cost of VRV-systems remains significantly higher, and their marginal productivity (volumes of refrigerated rooms) is limited (up to several thousand cubic meters).

- Some aspects of refrigeration design

- The chiller is overall (all three dimensions noticeably exceed a meter, and the length can exceed 10m) and heavy (up to 15 tons) equipment. In practice, this means the almost unconditional need for the use of unloading frames to distribute the mass of the chiller over a large area with the choice of acceptable support points. Standard frames are far from always suitable for each specific case, therefore, most often, special design is required.

- The VMT-Xiron chiller has 1-4 compressors, 1-12 fans, 1-2 pumps, which causes a whole gamut of negative vibrations, therefore, the chiller is installed on vibration mounts of the corresponding load-bearing capacity, and all pipelines are connected through vibration inserts of the corresponding diameter .

- As a rule, the connecting diameters of pipelines of a chiller are smaller than those of a main pipe (usually one, sometimes two sizes), so a transition is required. It is recommended to install a vibration insert directly at the chiller and immediately after - a transition. Due to significant hydraulic losses, it is not recommended to remove the transition from the unit.

- In order to avoid clogging of the evaporator on the coolant side, a filter must be installed at the inlet to the chiller.

- In the case of a built-in hydraulic module, a check valve is required at the outlet of the chiller to prevent water from moving against the design water.

- To regulate forward and reverse flows, a jumper between them with a differential pressure regulator is recommended.

- Finally, the documentation should always pay attention to which coolant the data are for. The use of non-freezing coolant by an average of 15-20% reduces the efficiency of the refrigeration system.

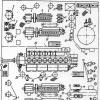

The hydraulic circuit of the chiller, hydraulic module

The scheme of operation of the chiller with an air condenser and a winter start-up system (monoblock design, without hydraulic module)

Specification

- Danfoss compressor

- High pressure switch KR

- Stop valve Rotolock

- Differential valve NRD

- Linear receiver

- Stop valve Rotolock

- Filter drier DML

- Sight glass SG

- Solenoid valve EVR

- Thermostatic control valve TE

- Filter drier DAS / DCR

- KR low pressure switch

- Stop valve Rotolock

- AKS temperature sensor

- FQS Fluid Relay

- Electric shield

The scheme of operation of the chiller with an external air condenser and a winter start-up system (without hydraulic module)

Specification

- Danfoss compressor

- High pressure switch KR

- Stop valve Rotolock

- Oil Separator OUB

- Check valve NRV

- Differential valve NRD

- KVR condensing pressure regulator

- GBC ball valve

- Air cooling condenser

- Ball valve GBC

- Check valve NRV

- Linear receiver

- Stop valve Rotolock

- Filter drier DML

- Sight glass SG

- Solenoid valve EVR

- Coil for Danfoss Solenoid Valve

- Thermostatic control valve TE

- Brazed plate evaporator type B (Danfoss)

- Filter drier DAS / DCR

- KR low pressure switch

- Stop valve Rotolock

- AKS temperature sensor

- FQS Fluid Relay

- Electric shield

Scheme of operation of the chiller with a water-cooled condenser and with condensing pressure regulation

Specification

- Danfoss compressor

- KP high pressure switch

- Stop valve Rotolock

- Condenser water cooling plate solder type B (Danfoss)

- Water control valve WVFX

- Filter drier DML

- Sight glass SG

- Solenoid valve EVR

- Coil for Danfoss Solenoid Valve

- Thermostatic valve TE

- Brazed plate evaporator type B (Danfoss)

- Filter drier DAS / DCR

- KP low pressure switch

- Stop valve Rotolock

- AKS temperature sensor

- FQS Fluid Relay

- Electric shield

Hydraulic module diagram for a single-pump chiller

Specification:

- Thermally insulated open tank

- Pump

- Ball valve

- Collapsible connection

- Pressure gauge

- Consumer outlet

- Water inlet

- Bypass valve

- Coarse filter

- Duct control relay

- Visual fluid level control

What is a fan coil: how it works and how to choose a device

A fan coil is an indoor unit of a chiller-fan coil type air conditioning system that can cool or heat the air entering it. It is used to maintain the necessary indoor climate throughout the year. This article discusses the principle of operation of such devices, their varieties, as well as the main pros and cons.

By the principle of operation, the fan coil is very similar to the indoor unit of the split system. The main difference is the coolant: instead of the refrigerant, the fan coil uses ordinary water or a non-freezing solution. The liquid cools or heats the incoming air, which is brought to the desired temperature and returned to the room. The resulting condensate is diverted to the street or sewer using a pump.

As in the case of heating radiators, often several fan coils are often installed in the same room at once - the required number depends on the power of the devices and the area of \u200b\u200bthe room. In addition, they can be connected to the supply ventilation, which allows the use of devices in a mixed mode (to mix the air received from the inside with fresh air).

Temperature control is carried out using the electronic system control unit, temperature sensors and various valves. Complex air conditioning systems also use central air conditioners, which are responsible for cleaning and humidifying the incoming air.

Types of chiller-fan coil systems

There are two main types of chiller-fan coil systems:- Single-zone system. It is mainly used for servicing large areas with uniform heat distribution, since all single-circuit fan coil units connected to it are heated and cooled at the same time.

- Multizone system. It uses fan coils with double-circuit heat exchangers, which allows to separate the supply of cold and hot water. Devices in such a system can simultaneously provide different air temperatures in different rooms.

Varieties of Fan Coils

All fan coil units operate on the same principle - devices differ only in installation method. Four main types of fan coils can be distinguished:- Cassette

- Floor standing;

- Wall mounted

- Channel.

- Single-threaded (air is discharged from the device in one direction);

- Dual-flow (two air flows in different directions from the device);

- Four-flow (models of this type produce four air flows, which makes them the best choice for air conditioning large areas).

How to choose a fan coil

When choosing a fan coil, the following device parameters should be considered:- Type (cassette, floor, wall or channel);

- Power (the minimum indicator in watts can be obtained by multiplying the area of \u200b\u200bthe air-conditioned room by 100);

- Energy efficiency (relevant only for large air conditioning systems, since fan coils consume quite a bit of electricity);

- Noise level (it is recommended to use devices with quiet fans, the noise level of which does not exceed 60 decibels).

Advantages and disadvantages of fan coils

Chiller-fan coil systems are popular due to a number of advantages compared to traditional split systems. Among the advantages can be identified:- Scalability. The distance between the units in split systems does not exceed 15 meters due to the refrigerant used in them. At the same time, the distance between the chiller and the fan coil can exceed hundreds of meters, which makes it easy to expand the system if necessary.

- Universality. Unlike air conditioners in standard split systems, fan coils are able to function non-stop throughout the year.

- Safety. Fan coil coolants are much safer in comparison with gas refrigerant used in split systems.

- Large system sizes. Due to the impressive dimensions of the chiller-fan coil system, its installation is advisable only in spacious buildings.

- Poor filtering quality. Filters for air purification built into fan coil units do their job much worse than their analogs in split systems.

- High installation complexity. Due to the large size and weight of the chiller-fan coil systems, it takes a lot of time and effort to install them.

Drycoolers: features and types of devices

Drycooler, or - is a fan apparatus used to cool the coolant by blowing it with street air. It is used both in small air conditioning systems - the fancoil chiller, and in large industrial enterprises. On this page you can find basic information about drivers, as well as a list of the most famous manufacturers of these devices.

The principle of operation of a drycooler

The design of the drycooler includes three main components:- Plate heat exchanger. It can be V-shaped, horizontal or vertical. Most often made from aluminum or copper. Efficient heat transfer is ensured by the high number of fins, and, as a consequence, the large surface area of \u200b\u200bthe heat exchanger.

- One or more fans. Most drycoolers are equipped with axial cooling impellers with a radius of 200 to 350 mm. In large devices with V-shaped heat exchangers, fans with a diameter of up to 1000 mm are allowed. In addition, centrifugal fans can be used in high performance industrial cooling systems.

- Protective and regulating automatic equipment responsible for maintaining the required temperature of the coolant and changing the speed of the fans.

- The heated coolant (ordinary water or non-freezing solution) is fed to the inlet of the drycooler, where its temperature drops to the temperature of street air. The cooling level can be adjusted by changing the fan speed. The fluid is supplied using a circulation pump. After that, the coolant is fed back to the equipment to be cooled, and then the cycle repeats.

Advantages and disadvantages of dry cooling towers

Drycoolers have several advantages. These include:- High energy efficiency;

- Ecological safety (energy carrier circulates in a closed loop, and, as a result, does not evaporate, keeping the level of air humidity at the same level);

- Easy to install, operate and service;

- Low cost of equipment;

- Easy scaling (new blocks are easily added to the existing cooling system);

- When working with drycoolers, you can use any non-freezing solutions.

- The performance of the devices depends on the temperature of the street air (problems may occur during periods of peak temperatures in winter and summer);

- Drycoolers consume more power than standard evaporative cooling towers.

Scope of Drycoolers

Due to their good energy efficiency and low cost, drycoolers are popular in a number of applications. They can work both independently and as auxiliary equipment together with refrigeration units. In particular, dry coolers are used:- In industries requiring large volumes of coolant;

- In the industry for cooling coolants in refrigeration and molding equipment, as well as heat removal from extruder engines, machine tools and generators;

- In construction, to reduce the temperature of refrigeration units and generators;

- For free cooling of air in public and industrial buildings (freecooling).

- A large assortment of models and configurations of drycoolers allows you to choose an installation with suitable characteristics for any operating conditions, so every year their popularity only increases.

The chiller with a remote condenser is reminiscent of a chiller based on a water condenser in design. The chiller itself is installed indoors, and the condenser is outside. Between themselves they are connected by a system of freon pipelines. Similar chillers are available in several versions. They can vary in power and can be equipped with automatic control systems. The compact indoor unit does not require much space indoors, and the remote condenser is reliably protected from weather conditions.

The main difference of such a chiller from analogs with a water condenser is that in its circuit:

- It is not necessary to use an intermediate coolant and powerful circulation pumps. The probability of freezing of the coolant is minimal, so there is no need to use a dual-circuit cooling system.

- Only the chiller itself should be located indoors, while the noisiest part of the equipment is the condenser, which is installed on the outer wall of the building or its roof, which reduces the noise level in the room and saves the interior space. Both units are interconnected by pipes with refrigerant.

5 reasons to purchase chillers from AquilonStroyMontazh

- Attractive prices and flexible discount system

- All necessary supporting documents

- Warranty service for purchased equipment

- Huge selection of products

- High quality and the shortest lead times

SUBMIT YOUR APPLICATION

Advantages of a chiller with a remote condenserSuch chillers have a number of advantages:- Easy maintenance of the installation. The automation system is reliably protected from adverse weather conditions. Since the entire piping system is located indoors, there is no need to use non-freezing liquids. As a coolant, you can use ordinary water. Therefore, this type of chiller is usually made on the basis of a refrigeration unit with a water condenser. Chillers of this type can be operated year-round for air conditioning of industrial premises.

with a remote condenser from a chiller with a built-in condenser (monoblock) is the absence in its body of the final heat exchanger - a condenser. For this reason, it is also called a "non-condensing" chiller. The capacitor itself is present in the design, but is implemented as an assembly mounted separately from the chiller.

Fundamentally, the operation of non-condensing chillers does not differ from that of monoblock structures, but it looks different in a schematic way (see Fig.): An intermediate heat carrier (usually water) moves along a looped circuit passing through a heat exchanger (evaporator) of a refrigeration unit. There, heat is transferred from the coolant to the refrigerant (freon). Freon evaporation is provided by a system of valves, temperature and pressure sensors, and its circulation is provided by a compressor. This part of the circuit is common to all types of chillers.

In non-condensing chillers, the internal (freon) circuit is only partially located in the housing of the refrigeration unit and has conclusions for connecting its external part, in which the condenser is located.

The principle of the location of the final heat exchanger separately from the main refrigeration equipment helps to significantly increase the cooling capacity of the entire system, without a significant increase in energy consumption. A similar effect is achieved by installing capacitors in places of free interaction with the outside atmospheric air - on the roofs of buildings or on open areas near them. In this way, air-cooled condensers are mounted. Liquid-cooled condensers can (and preferably) be installed indoors by moving the heat exchanger of the additional water circuit out.

Advantages and disadvantages of a remote condenser chiller

Compared to a chiller with a built-in condenser, the “non-condensing" chiller has many positive qualities, namely:

- - a more favorable ratio of indicators of cooling capacity and energy consumption;

- - lack of need for additional heat removal from the room in which the chiller is located;

- - the possibility of the initial layout of the chiller with condensers of various designs, dimensions and power, or alteration in a similar way to an already installed system. In the latter case, there is no need to replace the refrigeration machine;

- - low noise due to the placement of cooling fans outdoors. This feature also allows you to use the most economical option of equipping the condenser with axial fans;

- - effective cooling through "free cooling" (free cooling without forced blowing) in the cold season;

- - multigrade use with liquid-cooled condensers (with ethylene glycol as a coolant in the auxiliary circuit). In the case of cooling with running water, it is possible to continuously obtain hot water (if there is a consumer).

The disadvantages of a chiller with a remote condenser are more often manifested in the following:

- - more complex, and therefore - more expensive installation in comparison with monoblock units;

- - the use of liquid-cooled condensers significantly increases the cost of the entire system;

- - the limited length of the connecting paths between the chiller and the remote condenser.

- However, the last of the drawbacks is very doubtful, as experienced adjusters know many ways to eliminate it.

Air-cooled condensers are chillers that are used to heat or cool a heat transfer fluid. Water or antifreeze (propylene or ethylene glycol) is used as a heat carrier. Depending on the principle of operation and heat removal, chillers can be divided into air-cooled and water-cooled models. Most often, air-cooled units are used. In modern systems, air chillers act as heat carriers. The heat from the coolant is taken over by the evaporator, and is responsible for the discharge of this heat to the outside. The easiest way to transfer heat to the outside is to transfer it to the outside air. This is exactly what the condenser in air chillers does.

Air cooling condenser

A modern air-cooled condenser is presented in the form of a tubular-fin heat exchanger. The principle of operation is that the working substance flows through the tubes of the refrigeration circuit. As this substance is often called.Tubes and lamellas are blown outside. In the process of blowing, the hot tubes with refrigerant are cooled. It is also necessary to achieve high efficiency of the chiller itself for quick cooling of the refrigerant. There are several ways to achieve this goal.

First, special fins are mounted on the tubes for cooling. For this, copper tubes are most often used in combination with aluminum fins. The thickness of the ribs and their frequency must be designed based on considerations of the efficiency of the system and maximum heat dissipation. This will achieve the greatest efficiency of the entire system.

Secondly, it is important to design correctly design features heat exchangers.

Design features of modern air-cooled condensers

It must be ensured that, from a structural point of view, the maximum amount of air passes through the condenser. At the same time, a high level of heat removal will be provided. There are several ways to achieve such results.Initially, all the capacitors were made rectangular, and installed them vertically. They were mounted on the sides of the refrigerator itself. With the development of technology and changing approaches, this design has been modified and improved. To do this, they began to use new capacitors with a W-shape, which allowed to significantly improve work efficiency.

This solution helped to optimize the air flow as much as possible and provide efficient and quick cooling. Chillers began to work more productively, while reducing power consumption for condenser fans. It was also possible to improve the heat sink and lower the overall condensation temperature.

It should be understood that even a decrease of 1 ° C in the condensation temperature improves the efficiency (cooling capacity) of the operation of the refrigeration machine. This solution leads to an increase in energy efficiency by 3%, while maintaining the same generated refrigeration capacity.

Varieties of air-cooled chillers

Fans for air-cooled condensers

A fan is used to drive outside air through a condenser. Often, it must be installed on top of the refrigeration unit: air is drawn in from the sides of the chiller, then passes through the condenser, thereby cooling it, and then is thrown back into the street strictly vertically upwards.In addition, considerable attention is paid specifically to fans, since they are represented by the second largest energy consumers only after a compressor and, possibly, a pump.

Axial Fan Chillers

The process of cooling condensers occurs through the influx of air from the environment. The main advantage of using such equipment is a unique opportunity to use for the implementation of air conditioning systems, including unused space. Its main disadvantage is noise, which inevitably is a concomitant component during the operation of mechanisms. To minimize or eliminate such a drawback, manufacturers use special fans that are equipped with a low noise level and have specially shaped blades. It is worth noting that quite often this leads to an increase in certain dimensions of the structure, which is why the consumer may be offered such an alternative as low noise or small sizes. Quite often they produce a chiller with a remote condenser when it is located on the street, and the refrigeration module itself is indoors.

Centrifugal Fan Chillers

A chiller equipped with a centrifugal fan must be installed inside buildings. Both the influx of cooling air and the removal of heat are due to the duct system. In turn, centrifugal fans, which are characterized by an impressive static set, which makes it possible to overcome air duct resistance, are able to move air. An important advantage of this type of equipment is all the seasonality of the work performed, it can be used under various weather conditions, as well as ambient temperature. In order to avoid a lack of installations for the units, a special area of \u200b\u200boverall size inside the structure should be strictly allocated. In addition, the creation of a mandatory duct network will require additional costs.

Chiller principle of operation - refrigeration cycle

is a type of refrigeration machine that is used for all types of cooling. This device operates due to the refrigeration cycle of the vapor compression type. A similar cycle is also used in conventional air conditioners. In general, artificial cold is obtained using simple physical processes - expansion, compression and condensation of working substances or refrigerants.The concept and features of the refrigeration cycle

The principle of operation will help to quickly determine the model of the chiller when buying. And here you can not do without determining the refrigeration cycle. This is a circular process that is used when cooling in chillers. The refrigerant cycle includes 4 basic steps:- Compressor. This unit is a key component of every refrigeration unit. It maintains normal refrigerant flow in the system. The compressor enters the refrigerated low-pressure refrigerant in the form of steam, which undergoes compression to increase pressure and temperature. Due to the small number of moving components, the compressor is characterized by high reliability, low vibrations and minimal noise during operation.

- air condenser. Steam comes here, which under pressure transforms into a liquid state. This process is called condensation. It is necessary to discharge the heat removed by the refrigerant into the environment.

- Flow regulator. At this stage, liquid refrigerant passes through the flow regulator, cooling and reducing pressure.

- Evaporator. Here the low-pressure refrigerant boils, taking heat from the air inside the room and transforming into a gaseous state. After the refrigerant in the form of gas again enters the compressor and the refrigeration cycle is repeated.

"Warm" operation

There are chillers that operate in the reverse refrigeration cycle, creating cold instead of heat. This process is similar to the reverse mode of the air conditioner. Here the condenser acts as, taking heat from the outside and transferring it to the coolant. The latter is more correct in this case to be called a coolant.Chillers have long been used to equip air conditioning systems. The scope of their use is quite wide: from offices and private homes, to medical institutions and large industrial workshops. The installations have gained such popularity due to their high efficiency, ease of use, and a variety of design options.

Depending on the installation location of the heat exchanger, the chillers can be monoblock (the chiller and condenser are in the same housing) or with a remote condenser unit. Most often prefer a one-piece design, which also includes a pumping station. The most common option is systems with an air-cooled condenser. This design is mounted on the street to provide a full flow of air to the heat exchanger.

When is a remote capacitor used?

There are situations when it is necessary to separate the chiller and the heat exchanger. If the installation is used in the warm season, it successfully functions in the usual modification. But if the air temperature drops and reaches negative values, the possibility of equipment failure due to freezing of water increases. To avoid this, water is removed from the system and the chiller is mothballed.

When it is required to ensure continuous operation of cooling equipment, water is replaced with a more expensive non-freezing liquid at a cost. The above procedures are quite time-consuming and costly in financial terms, since only professional workers with relevant experience should perform them.

The task is greatly simplified if you use not a monoblock chiller, but equipped with a remote condenser. In this case, you can do without draining or replacing water with another liquid. The chiller and pump station are located in a separate room, which is heated, and the heat exchanger is taken out to the street, since it still requires a large flow of air.

The principle of operation of the installation and its configuration does not change. The main elements of the chiller will be:

- Compressor unit

- Evaporator.

- Heat exchanger.

- Throttle device.

The only drawback is the need to create a route connecting the cooling unit and the condenser. You must also consider the difference in height between the blocks. Therefore, when selecting equipment, you should pay attention to these two parameters and determine in advance a convenient installation location.

It is not difficult to choose a chiller in the Smart Trading catalog; you can always count on the help of qualified managers who not only recommend high-quality equipment at a reasonable price, but also arrange delivery and professional installation.