The proterm leopard boiler does not turn on. Error codes for gas boilers Proterm - malfunctions and solutions. ⚫ Faulty outside temperature sensor

⚫ Floor-standing gas boilers of the Proterm "Medved" series 20 30 40 50 KLOM

This section lists some of the fault codes along with the appropriate corrective action that the user can take to get the equipment working again.

If after that the equipment does not start to work - call a specialist from the service department.

⚫ Insufficient pressure in the heating system

⚫ Explanation: It is required to feed the heating system with water. If the error repeats over time, then there is a leak.

The problem can be both in the boiler (for example: the expansion tank is faulty) and in the pipeline of the heating system.

Check the pressure in the heating system, inspect the pipelines to understand where the leak is.

⚫ Flame loss

This error means irreversible blocking of automatic ignition and cessation of gas supply through the gas valve, i.e. LOSS OF FLAME. Such a blockage can occur in cases where, being in the open gas valve mode, the automatic ignition does not receive a return signal about the presence of a flame from the ionization electrode.

The boiler will turn off and the display will show error F1. This malfunction can also be caused by the operation of safety elements - an emergency thermostat or a combustion products thermostat. Low inlet gas pressure, incorrect electrical connection (phase and zero reversed) can also cause flame loss. To clear the fault, press the RESET button (fig.1, pos.5). If the fault cannot be cleared with the RESET button, contact your service organization.

⚫ Explanation: Most often means that the gas is not connected, less often - overheating. If the boiler does not hold the flame when ignited, check that the boiler is plugged in correctly. In most cases, it is enough to rearrange the plug on the other side.

⚫ Faulty heating water temperature sensor

⚫ Description: Indicates a malfunction of the boiler temperature sensor or a decrease in the temperature of the heating medium below 3 °C. The boiler will be blocked, as switching on at a temperature below 3 °C is not allowed due to the possible formation of ice. Contact a service organization.

⚫ Explanation: Incorrect sensor readings can cause such an error. Most often this means that the sensor needs to be replaced. It is necessary to check the sensor circuit, if it is faulty, replace the sensor.

Often such an error occurs when starting the boiler in the cold season, when the water temperature in the system has dropped below 3 ° C. To start the system, it is necessary to increase the temperature of the coolant in the boiler.

⚫ Boiler overheating

⚫ Description: Indicates that the heating medium temperature is above 95 °C. The boiler will shut down. After the temperature of the coolant drops below 95 °, the boiler can automatically resume operation.

⚫ Explanation: If the water circulation in the system is disturbed, overheating may occur. It often occurs in floor-standing boilers of high power. It is necessary to eliminate the cause of overheating and restart the boiler. You may need to reset the thermal fuse.

⚫ Faulty DHW sensor

⚫ Description: The boiler will stop working to heat the boiler. This malfunction does not affect the heating mode.

⚫ Explanation: Incorrect readings of the DHW sensor can cause such an error. Most often this means that the sensor needs to be replaced. Check circuit/replace sensor.

⚫ Faulty outside temperature sensor

⚫ Description: The boiler operates without restrictions, but the temperature of the coolant is controlled by the boiler sensor. If the boiler is not operating in equithermal mode, then such a message cannot appear.

⚫ Explanation: First of all, check the circuit - is it connected, is there a break. If everything is in order, replace the sensor.

⚫ Wall-mounted gas boilers of the Leopard series

This section lists the main fault codes along with the appropriate corrective actions that the user can take to restore the operation of the equipment.

Other faults should only be repaired by a qualified technician.

When a fault code image appears, press the "RESET" button.

If after that the equipment does not start working, call a specialist from the service department as soon as possible.

⚫ Insufficient pressure in the heating system

⚫ Description: The pressure drop of the circulating water in the system (below the value of 0.7 bar). The boiler switches off automatically.

⚫ Explanation: Increase the hot water pressure in the heating system to a value in the range of 1 - 2 bar. After adding water to the heating system, the boiler will automatically resume operation. If the drop or increase in water pressure in the heating system recurs, call an authorized service.

⚫ Flame loss

⚫ Description: The flame went out as a result of stopping the gas supply to the boiler

⚫ Explanation: Turn off and after a short pause turn on the boiler again with the main switch (RESET). If the problem persists, call an authorized service.

⚫ Faulty heating water sensor

⚫ Description: The boiler cannot continue to work because. no information to what temperature the water is heated.

⚫ Explanation: Check temperature sensor circuit. If there is no open or short, then the sensor must be replaced. Contact customer service.

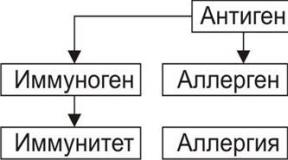

Proterm heaters are equipped with a self-diagnosis system. Due to this, errors in the operation of the Leopard boiler are displayed in the form of codes on the display. Their decoding will help determine the location of the problem in order to quickly restore the device to working capacity.

Features of the operation of the Protherm Leopard boiler

The device has a cast-iron base, which gives a high efficiency of 90-92%. A double-circuit gas boiler works simultaneously for heating and hot water supply (DHW). The design is equipped with a bithermic heat exchanger of the "pipe in pipe" type. Water circulates through the outer tube for the heating system, and through the inner tube for hot water.

Built-in mode "Winter-Summer" allows you to save on fuel consumption. The boiler can run on gas from the main or from a cylinder. The combustion chamber is open and closed.

Error codes

Usually the manufacturer indicates the meaning of the faults in the instruction manual. But not everyone understands the technical language, moreover, the user manual may be lost. Therefore, we provide transcripts in the table.

| Symbols on the display | Meaning | Remedy |

| A6 | Low room temperature. | If the temperature drops to 0 degrees, the equipment will freeze. Connect a radiator to heat the room. |

| F0 | The pressure dropped below 1.5 bar. | What to do:

|

| F1/F29 | The flame went out. Lightning light flashes. | Fuel supply cut off:

|

| F2 | The water sensor in the heating system is out of order. | Measure the resistance of the sensor, inspect the integrity of the wiring, tighten the connections. |

| F3 | The appliance has overheated. | What to do:

|

| F4 | The DHW temperature sensor is not working. The lightning diode blinks. | Tighten the contacts from the sensor to the electronic board. Replace defective element. |

| F5 | The external temperature sensor is defective. If it is not present, the system gives a signal about power outages. |

|

| F6 | Failure of the differential relay, fan, thrust sensor. | Verify:

|

| F7 | Communication problems. No contact between LCD and electronic module. |

|

| F8 | Fuel valve failure. | Diagnosis of wiring, valve coils. |

| F9 | Settings failure. | Reconfigure the metrics. |

| F10 | Short circuit (short circuit) of the temperature sensor at the feed. | Testing with a multimeter, installing a new part. |

| F11 | Short circuit of the NTC controller on the return line. | |

| F12/F13 | Short circuit NTC hot water heater. | |

| F14 | Closed collector NTC. | |

| F15 | Short circuit NTC venting. | |

| F16 | Short circuit NTC thrust. | |

| F17 | Short circuit NTC manifold return. | |

| F18 | Short circuit NTC water heater grounding. | |

| F19 | Short circuit NTC hoods. | |

| F20 | The thermal fuse has switched on. | Reduce the temperature in the circuit, inspect the fuse. |

| F21 | Blockage of the device due to an increase in the set values. | Contact the service center. |

| F22 | Little water in the system. |

|

| F23/F72 | Not enough fluid. Thermosensors on both lines give different readings. | Make sure the sensors are working. |

| F24 | The amount of coolant has been reduced. The temperature is rising too fast. | Same as F22. |

| F25 | Too hot water comes out when you open the faucet. | Adjust the settings on the thermostat. |

| F26 | The valve winding current is not correct. | Call the experts. |

| F27 | The burner flame is signaled, although no fuel is supplied. | Diagnostics and replacement of the ionization electrode. Inspection of contacts, wiring. |

| F28 | The first ignition attempt failed. | Try again. |

| F30 | Blocking sensor contacts are open. | Repair the chain, put a working element. |

| F31 | Short circuit of the blocking sensor. | |

| F32/F33 | Anti-freeze mode is on. The fan does not rotate correctly. | Adjust the fan rotation, turn off the mode in the warm season. |

| F35 | Poor combustion products. | Clean up:

|

| F36 | Determining the presence of traction. For products with an open combustion chamber. | Light a match and bring it to the control window. In the presence of thrust, the flame will deviate to the side. Otherwise, it will burn evenly. |

| F37 | The fan blades are spinning abnormally. | Connection diagnostics. |

| F38 | When measuring, the frequency does not meet the standards. | Master's call. |

| F39 | Error in self-diagnosis. | |

| F41 | The fuel supply is adjusted incorrectly. | Change your settings. |

| F42 | Defective coding resistor. | Checking the state of an element. |

| F43 | The vehicle model is identified incorrectly. | Service call. |

| F49 | Low voltage on the eBus. | |

| F55 | Problems with the CO sensor. | |

| F58 | No contact with preheat. | |

| F60 | Fuel valve control problems + | |

| F61 | Problems with the regulation of the gas valve - | |

| F62 | The valve does not work. | |

| F63 | EEPROM problems. | |

| F64 | AOS error. | |

| F65 | Electronic parts overheat. | |

| F66 | The IIC bus is not working properly. | |

| F67 | Flame error. | |

| F70 | OSN problems. | |

| F71 | Opening of the water flow sensor. | Tighten connections. |

| F73 | Bad pressure sensor connection. | |

| F74 | Pressure controller wiring problems. | Loop replacement. |

| F75 | The pump is on but the pressure is not rising. | System restart. |

| F76 | The thermal fuse on the primary radiator has failed. | Installing a good fuse. |

| F80 | SH error. | Seek help from a specialist. |

| F81 | Circulation pump malfunction. | |

| F82 | Problems with the anode tester. | |

| F90 | No connection to the APC module. | |

| F91 | The sensor on the APC module is faulty. |

Users sometimes complain that the Leopard boiler hums and makes noise during operation. Check the heat exchanger for scale. If the tubes are overgrown with plaque, clean them. For this, a reagent pump is used. The system is pumped, then washed with clean water.

At the first sign of a problem, do not delay the repair. Inspect the equipment, find the cause of the breakdown. Sometimes it's just the wrong settings, then you should follow the instructions. If you smell gas in the room, quickly turn off the valve and contact the gas service.

Of course, most readers are concerned about the issue of "technical treatment" of heating devices and how to fix the problem. Before covering this issue, you need to know the device, product characteristics and its capabilities.

The diagram shows the device of a gas boiler Proterm of a Czech manufacturer.

The main technical indicators include:

- Efficiency: 90-92%.

- Possibility of adjustment: "winter-summer".

- The function of heating water in boilers.

- Installed overheating protection.

- Ability to work in several directions: on main gas and liquefied coolant.

- The gas boiler is made on a cast-iron base.

This is the minimum set specifications for a simple layman, which you need to know. More detailed information is indicated in the technical data sheet attached to the purchase of the product.

Types of Czech gas-fired boilers

The manufacturer offers the domestic buyer to purchase equipment of its own production, which are divided into:

- by the number of circuits: a double-circuit version of the boiler or a single-circuit design;

- with installation orientation: wall or floor version.

On the domestic market, you can purchase various modifications of Proterm heating equipment.

Types of gas boilers Proterm are the most interesting for the domestic market

On sale there are many modifications. The most common are gas two-chamber boilers with biometric heat exchangers: Leopard and Lynx.

The equipment is made at a high technological level and complies with EU standards. However, no matter how good the technique is, it tends to fail at the most inopportune moment.

Read below about malfunctions of heating devices and troubleshooting methods.

Gas boiler Proterm Leopard equipment malfunction.

There are certain error codes, thanks to which you can understand what happened to the equipment. The most common malfunctions of the boiler leopard 24.

F0

Signals to us about a decrease in the pressure of incoming water with values below 0.6 bar. If the heating water pressure is low, the system switches off automatically. This is signaled by a built-in diode (see the "Pointer" symbol).

In this case, it is necessary to increase the value of the incoming liquid to the level of 1.2-2 barrels. After stabilization of the pressure, the boiler will automatically resume operation in the planned mode.

F1

The flame is gone. The gas supply was interrupted and the wick went out. You need to pay attention to the emergency thermostat. Try to restart it.

Another reason may be a turned off draft sensor (we are talking about boilers and chimneys).

Another problem that affects the disappearance of the flame is the wires are reversed: phase and zero.

The loss of the flame can be caused by a problem with the automation responsible for ignition, the gas valve and malfunctions in the control system.

F2

The heating water sensor has failed. In this case, the malfunction is due to a break in the above element. It is possible that t0 of the cooling water has crossed the mark below 3 0 С. The system is disabled. The resistance of the sensor needs to be checked. Pay attention to the cables running from the sensor to the control panel. Find out, t 0 RH, inspect the system for freezing.

F3

Often malfunctions of the gas boiler Leopard 24 associated with overheating. Cooling down, the system resumes its work. It is necessary to check the heating pump: it may be clogged.

Photo: Heat exchanger of the Leopard 24 gas boiler.

Check the condition of the heating filter and check the heating water heat exchanger. The reason is the same: clogging of the working elements.

On a note. In work, use the non-freezing mixture recommended by the manufacturer: "AlycolTermo".

F4

The water sensor is out of order. There was a short circuit of the sensor responsible for the t 0 mode of the tank. In this case, the operation of the boiler will continue in the mode: “Heating water heating”.

Heating of incoming water is switched off. The reason may lie in the resistance of the sensor.

Please note that when the circuit is broken, the error code is not displayed! The control unit will show that the storage tank and or the sensor are not connected.F5

External sensor failed operating in equithermal regulation mode. Attention should be paid to correct connection of the sensor and the element itself.

It is clear that this is an incomplete list of possible technical failures in the operation of Proterm gas boilers.

For more detailed instructions and errors, see technical documentation. In addition, you can get knowledge on the Internet.

There are plenty of videos on the net that talk about problems and how to fix them.

For example, learn how and with what, at home, to clean the heat exchanger.

Without a doubt, some of the problems can be fixed on your own. But most breakdowns require the intervention of specialists.

In matters of safety and quality elimination of technical failures in the operation of gas-fired boilers, it is necessary to seek the help of specialists at a service center.

Gas boiler Proterm Leopard malfunction shows 104.Do not take risks and self-medicate. This may lead to serious problems. Therefore, you will have to shell out money from your pocket for unplanned re-repairs.When choosing a technical assistance center, pay attention to the availability of certificates and the duration of the center: how long the company has been providing this kind of service.

Speaking of quality, it makes no sense to use the workshops located near your home. Moreover, the masters go to you at the specified address.

Carry out regular preventive maintenance of the equipment. This is the key to the stable operation of the gas boiler.

Finally

No matter how manufacturers praise their products, problems still arise. Separate elements and blocks fail. This cannot be avoided.

This means that it is necessary to approach the issues of technical problems calmly and carefully.

High-quality repairs with a guarantee for the work performed can only be given by specialists of the service center. They use original parts and accessories.

If you are confident in your abilities, you can take on some of the work to eliminate deficiencies. But this is a risk: keep that in mind. Good luck to you!

This article contains all possible malfunctions and options for their elimination, as well as error codes for Proterm boilers (Protherm). All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article.

Error code F00 - Malfunction of the heating temperature sensor (NTC2)

Feed sensor (NTC 2) disabled.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

Error code F01 - Faulty heating temperature sensor (NTC5)

Return sensor (NTC 5) disabled.

Error code F10 - Faulty heating temperature sensor (NTC2)

Short circuit of the supply sensor (NTS).

Error code F11 - Damage to the heating temperature sensor (NTC5)

Short circuit of the return sensor (NTC 5).

Error code F13 - Malfunction of the boiler sensor (NTC 1)

Sensor short circuit: shunt instead of sensor at X16:

- Check sensor connections.

- Check sensor cables.

- Check sensor.

Error code F20 - Overheating fault (97C measured by heat flow sensor) (NTS)

No heating water flow in the Protherm boiler circuit:

- Make sure the pump is working properly.

- Unlock the pump.

- Make sure the heating taps are open as well as the bypass.

- Check Status plate heat exchanger if the fault occurs in hot water mode.

- Check the condition of the heat filter.

Error code F22 - Error: no water in the installation (less than 0.3 bar) (Cp)

- Leaking heating system - fill the system.

- PSU leak - make sure there are no leaks.

- Expansion tank defective - Check expansion tank.

Error code F23 - Error: the maximum difference between the supply and return temperatures has been reached (35K) (NTS)

Water circulation problem (low flow):

- Check the connector for the thermal output and return sensors.

- Check pump speed.

- See error F20.

Error code F24 - Water circulation malfunction (temperature rises faster than 10K / s) (NTC2, NTC5)

Poor pump performance or low water pressure:

- See error F20.

- The heating taps are closed, the bypass does not work.

- The pump is disabled or blocked.

Error code F25 - Error in the receipt of combustion products (only for options with an open chimney) (K11)

The protection device (K11) in the draft outlet has detected an excess of smoke.

Troubleshooting Help:

- Check the exhaust pipe (connector, length, diameter, whether it is blocked or the chimney is blocked).

- Check the air supply to the room.

- Check thermostat.

Electric exhausts in the room with the device are prohibited.

Error code F26 - Error lack of required current through the stepper motor gas valve

Stepper motor disabled or defective:

- Check the stepper motor connector.

- Check engine.

Error code F27 - Error in the receipt of the flame signal (ionization current) despite the closed gas valves

Violation of the process logic:

- Check the flame detection electrode.

- Check the main board of the Protherm boiler.

- Check the tightness of the gas fittings.

Error code F28 - No flame detected during ignition

- Incorrect gas valve settings - check gas valve setting.

- Gas valve defective - check gas valve.

- Ignition electrodes are defective - check the condition of the electrode (corrosion).

- Bad grounding - fix.

Error code F29 - Error: loss of flame during burner operation (FL)

- Insufficient or no gas - check the gas supply circuit (gas cock open).

- Carbon deposits on the ionization electrode - check the condition of the electrode (corrosion).

- Faulty ignition and flame control system - check ignition circuit connections.

Error code F33 - Malfunction of the differential relay (Pr)

The switch does not move to the off position. (OFF) when the fan is in the off position:

- Check differential relay (manostat).

- Debris in the path of the air flow control system (pitot tube, impulse tube).

- Blockage or icing in the smoke exhaust or air intake path.

- Front wind support.

Error code F42 - Faulty coding resistor

Coding resistor not as expected - check the coding resistor (R1) on the schematic.

Error code F61 - Main circuit board error

Gas valve control fault:

- Check all connections to the main circuit board.

- Check the electronic board.

- Check the product code.

- Restart the device.

Error code F62 - Electronic board error

Gas valve closing failure.

Error code F63 Main board error

The main board memory is defective.

Error code F64 - Main circuit board error

Quick changes in heat flow sensor and return parameters.

Error code F65 - Electronic board error

The temperature of the main board is too high.

Error code F67 - Boiler main board error

Flame signal failure on the main board.

Error code F68 - Fluctuating flame signal (FL)

See error F28.

Error code F70 - The user interface is not compatible with the electronic board

Invalid product code:

- Check the product code.

- Check the card identification number.

Error code F72 - Constant temperature difference between the supply and return sensor (NTS)

Heat flow and return temperature mismatch (constant difference):

- Check temperature sensor connector.

- Replace faulty sensor.

Error code F73 - Malfunction of the heat circuit pressure sensor (Cp)

Pressure sensor shorted or disconnected:

- Check sensor connector.

- Check sensor.

Error code F74 - Electrical malfunction of the pressure sensor

Electrical failure of the pressure sensor.

Error code F77 - External equipment malfunctions

External Gas Valve / Condensate Pump - Check equipment connections.

Error code F83 - Error: there is no water in the installation and the temperature does not rise when the burner is lit (NTC2, NTC5)

The circuit is not vented properly - see F22.

Error code F84 - Constant temperature difference between supply and return sensor (NTC2, NTC5)

- Flow and return temperature sensors reversed or disconnected - check temperature sensor connector.

- Faulty temperature sensor - Replace faulty sensor.

Error code F85 - Malfunction of supply and return sensors (NTC2, NTC5)

The flow and return temperature sensors are connected to the same pipe - check the temperature sensor connector.

Errors of floor boilers Proterm

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

Error F1 - Loss of Flame

This error means an irreversible blocking of the automatic ignition and stopping the gas supply through the gas valve, i.e. loss of flame. Such a blockage can occur in cases where, being in the open gas valve mode, the automatic ignition does not receive a return signal about the presence of a flame from the ionization electrode. The boiler will turn off and the display will show error F1. This malfunction can also be caused by the operation of safety elements - an emergency thermostat or a combustion products thermostat. Low inlet gas pressure, incorrect electrical connection (phase and zero reversed) can also cause flame loss.

To clear the fault, press the RESET button.

If the failure cannot be corrected, contact a service organization.

Error F2 - Malfunction of the boiler temperature sensor

Indicates a malfunction of the boiler temperature sensor or a decrease in the temperature of the heat carrier below 3 C.

The boiler will be blocked, as switching on at temperatures below 3 C is unacceptable due to the possible formation of ice.

Error F3 - Boiler overheating Protherm

Indicates that the coolant temperature is above 95 C.

The boiler will shut down.

After the coolant temperature drops below 95 C, the boiler will automatically resume operation.

Error F4 - Malfunction of the boiler sensor

The boiler will stop working to heat the boiler. This malfunction does not affect the heating mode.

Error F5 - Malfunction of the external temperature sensor

The device works without restrictions, but the temperature of the coolant is regulated by the boiler sensor.

If the device is not operating in equithermal mode, then such a message cannot appear.

2017-05-03 Evgeny Fomenko

The device and principle of operation of Proterm boilers

Let us consider in more detail the most popular models of the manufacturer Protherm.

Proterm Gepard 23 MTV (MTV)

This model of a wall-mounted double-circuit boiler belongs to the middle price segment. Equipped with the function of heating liquid for household needs, the power of the device is 23 kW. There are two modifications of the model on the market, natural (MOV) and forced (MTV) removal of the combustion product.

It is possible to control the operation of the boiler using a room thermostat or an outdoor temperature sensor. The design provides for a liquid crystal display, with the help of which the operation of the device is monitored.

Gepard 23 MTV does not need to be connected to a chimney system, since it has a coaxial smoke exhaust system, which makes it possible to install it in a room without a chimney. The built-in heat exchanger is made of stainless steel, a sensor is provided that controls the pressure in the system.

Works in two modes winter/summer, power adjustment happens thanks to a modulating torch. Water reaches the set temperature after 3 seconds after opening the tap, the efficiency is 91%.

The function of protection against freezing and overheating of the system is provided. From the pros - very easy to use, does not pollute during operation environment, affordable price.

Proterm Lynx

The installation method is wall-mounted, the boiler is designed for space heating and hot liquid heating. Depending on the area of the room, there are two power options 24 kW and 28 kW. Due to the forced removal of combustion products, it is possible to install it in a room without an equipped chimney, or if it is not technically possible to equip it there.

Boiler Proterm Lynx

Boiler Proterm Lynx

Despite the low cost, it has a good efficiency of 94%, while fuel consumption is low. It has two modes of operation: economical and comfortable. Thanks to the built-in electronics, automatic ignition occurs, and the burning of the flame is also controlled.

Water heating temperature control is carried out using an NTC sensor, which is installed at the outlet of the secondary heat exchanger. Equipped with a three-stage circulation pump, frost protection is provided when the temperature drops below 5 degrees.

Proterm Skat

Model range 6 kW, 9 kW, 12 kW, 18 kW, electric boiler, has the ability to step power adjustment, runs very quietly, suitable for heating small areas.

Boiler Proterm Skat

Boiler Proterm Skat

The device is single-circuit, designed for space heating, the efficiency is 98%, it is connected to a 220 V network. Due to the large number of functions, there is an excellent possibility of remote control.

Proterm Bear 40 KLOM

This is the most popular model in this line of floor cast iron gas boilers, as well as the Proterm KLOM 20, 30,40,50 models. This model is often used together with a solid fuel boiler as an additional heating device.

Boiler Proterm Medved 40 KLOM

Boiler Proterm Medved 40 KLOM

A definite plus is ease of use, high efficiency of 92%. Also in the Medved series there is a Proterm 40 KLZ line, which is equipped with a built-in 90 l boiler, it is possible to replace individual cast iron sections which significantly reduces repair costs.

Proterm Panther (Panthera)

Designed for heating offices, houses and providing hot water. Modifications with an open combustion chamber or sealed are possible. The throughput of hot water is 13-15 liters, the maximum heated area of \u200b\u200bthe room is up to 260 square meters.

It can work with low pressure, the presence of frost protection of the heating system, has a high degree of safety. Thanks to the display, it is possible to monitor the operation of the boiler.

Boiler Proterm Panther

Boiler Proterm Panther

The design provides for two heat exchangers, one for providing heat in the heating system, the other for hot water. Suitable for systems where it is necessary to maintain a minimum temperature, there is a “comfort” mode, when it is turned on, hot liquid flows from the tap after 2 seconds. There is a self-diagnosis system.

Proterm Jaguar

It belongs to the most inexpensive models of wall-mounted gas boilers, designed for an apartment or residential building. There are two options for power 11 and 24 kW, throughput 10 liters per minute, automatic flame modulation, independent operation of two circuits.

Boiler Proterm Jaguar

Boiler Proterm Jaguar

Basic error codes

f1

Error F1 (f1). Loss of flame, ignition blocked and gas supply to the gas valve cut off. This happens when the board does not receive a signal about the presence of a flame from the ionization electrode, while the gas valve is open, the protective mechanism is activated and the boiler is turned off.

It could also be due to insufficient gas pressure. To eliminate, press the restart button, and check if the gas valve is open, and it will be useful to check the plug in the socket, turn it over, changing the polarity.

Also, often the error F01 indicates an overheating of the thermostat, to eliminate it, try pressing the restart button on it. This problem very often occurs in the Proterm KLOM model.

f2

Error f2 (f2). The temperature sensor of the heating circuit has failed, or the temperature of the coolant has dropped below 3 degrees. The appliance is locked out because ice may form. Often this indicates a failure of the sensor, check it and, if necessary, replace it with a new one.

Heating circuit temperature sensor

Heating circuit temperature sensor

However, this situation can be caused by starting the device in the winter season, when there is really insufficient temperature in the system. To start the system, raise the temperature in the system.

f3

Error f3 (f3). This error indicates that the boiler has overheated and means that the permissible critical maximum of 95 degrees has been reached, the protection is activated and the boiler automatically turns off.

Wait until the temperature drops below this indicator, the boiler will start on its own. If this situation occurs again, reset the thermal fuse.

f4

Error f4. The DHW sensor failed, when this failure occurs, the boiler normally works to heat the heating circuit, and the heating of the liquid for domestic needs stops. Often, such a breakdown indicates either that the sensor is out of order and needs to be replaced, or the contacts are oxidized, clean and inspect them.

f5

Error f5. Damage to the external temperature sensor. With such a malfunction, the device works, but the temperature control is carried out by the boiler temperature sensor. To eliminate, check if there is a mechanical break in the boiler-sensor circuit, if there is no break, it needs to be replaced.

Boiler temperature sensor Proterm

Boiler temperature sensor Proterm

f6

Error f6 (f6). Indicates a break in the exhaust gas sensor. Ring the connecting wires between the sensor and the board. Perhaps the board is out of order, take it to a service center for diagnostics, or the sensor itself is faulty. This breakdown can be caused by a faulty ignition transformer, check it.

f7

Error f7. The instructions describe the error as a disconnect. This gap can be anywhere, and means that when connected to the controller, a signal does not come from one of the elements, or there is not enough voltage at the terminal on the control board.

It is necessary to visually inspect all the wires, ring them for a break, check all the connectors. It is also possible that the board itself has failed and needs to be repaired. If nothing can be found, seek qualified help from a specialist.

f8

Error f8 Indicates the opening of the NTC sensor circuit and the grounding of the DHW boiler. Ring this chain of connections, disconnect and reconnect these elements, as the contacts may have come off. If these manipulations do not work, replace the sensor.

f10

Error f10. Indicates a short circuit of the NTC temperature sensor on the supply line.

This fault appears on the display if:

- Happened short circuit in NTC device installed at the input of the OF. In this situation, it needs a complete replacement.

- Also possible if the voltage level in the circuit has decreased up to 0.40 V.

- A short circuit has occurred in the device plug. What to do in this situation? Only its complete replacement, it is not subject to repair.

f15

Error f15. Sensor short circuit reverse thrust. The combustion products controller is located at the top of the boiler, it is connected to the fan pipes.

It is necessary to disassemble, clean all the terminals, remove deposited formations from the tube. If this procedure did not bring results, a replacement with a new device will be required.

f20

Error f20 (f20). The safety temperature limiter has tripped. The flow temperature sensor may be connected incorrectly, causing the temperature to rise higher. allowable rate(95 degrees) or an open circuit has occurred.

Temperature limiter for gas boiler

Temperature limiter for gas boiler

Call her, if you do not find a malfunction, try reconnecting it. Check if the pump is working, bleed air. If you have not been able to solve this problem yourself, seek help from a specialist.

f22

Error 22. This problem indicates a low fluid pressure in the heating circuit of less than 0.3 bar.

Possible reasons for this:

- Fluid pressure sensor failure. Need to be replaced.

- Malfunction or blockage of the pump, or its work is not regulated. Clean it out and check for proper operation.

Add fluid to the system. Check all elements for leaks, as pressure may drop due to a leak, if it is found, eliminate it.

f23

Error f23. Excess acceptable level temperature difference between flow and return.

f24

Error f24. Low level liquid in the heating circuit, the temperature rises very rapidly.

Perhaps this happened due to:

- Pump interlocks, or its insufficient performance.

- Happened system airing, and, as a result, the pressure has decreased, blow it out.

- Highway overlap. See if all taps in the system are open.

f25

Error f25. The protection system against the penetration of carbon monoxide into the room has been triggered. Why does the boiler turn off? When this malfunction occurs, the relay contacts open due to a violation of the air flow circulation.

The reason may be:

f28

Error f28 (f28). Extinction of the flame when turned on.

The following causes of this malfunction are possible:

It will also be useful to clean the entire ignition group, including the burners.

f29

Error f29 (f29). Extinction of the flame during the operation of the boiler.

Consider the possible reasons:

- No gas supply to the boiler. Perhaps there is no gas in the line, you need to contact the gas service.

- Check grounding devices, phase, zero.

- The reason may also be burner clogging, to do this, remove the casing from the boiler by unscrewing the two bolts. Next, view the condition of the burner, if necessary, clean it.

f33

Error f33 (f33). The antifreeze protection system in the fan is activated. The contact in the relay does not close.

It is possible for several reasons:

f55

Error f55. Faulty carbon monoxide sensor.

You need to check the following:

- Status of contactors and relays. If sticking is found, then use fine-grained sandpaper to clean and degrease them.

- Maybe, faulty control board and it needs to be replaced.

f62

Error f62. Gas valve defective.

What should be done.

Read also...

- How to cook semolina porridge in milk and water without lumps correctly and how much: recipes and proportions with photos and videos, including for children In what dishes should semolina be cooked

- The most famous national Ukrainian dish

- The history of mushroom picking in Russia

- Birthday May 5 Characteristics of a man